Volvo launches EC530e and EC550e : the 50-ton excavators that look beyond their class

Volvo CE is launching two 50-ton machines - the EC530E and EC550E - excavators born to excel in heavy excavation, massive excavation and large-scale construction site preparation.

The two excavators deliver the same the digging and lifting forces as 60-ton machines and feature the highest engine power in their class, with high tractive effort and slewing torque. Combined with large buckets, the EC530E and EC550E are ideally suited for filling 30- to 40-ton articulated dump trucks; fewer loading passes are required resulting in shorter cycle times. This combination increases productivity by 20%.

These 50-ton machines have the same features as the larger machines. The heavily reinforced undercarriage is as strong and durable as that of a 60-ton class excavator and is supported by lower and upper frames that are both equally strong. The support frame of the EC550E has a long and wide undercarriage for added stability for heavy loads. The undercarriage of the EC530E has the same transport dimensions (and ease of loading) as the Volvo EC480E excavator.

Not only is the undercarriage robust: the boom and arm also have a larger shaft that increases strength when the going gets tough.

IMVT technology increases fuel efficiency with 25%

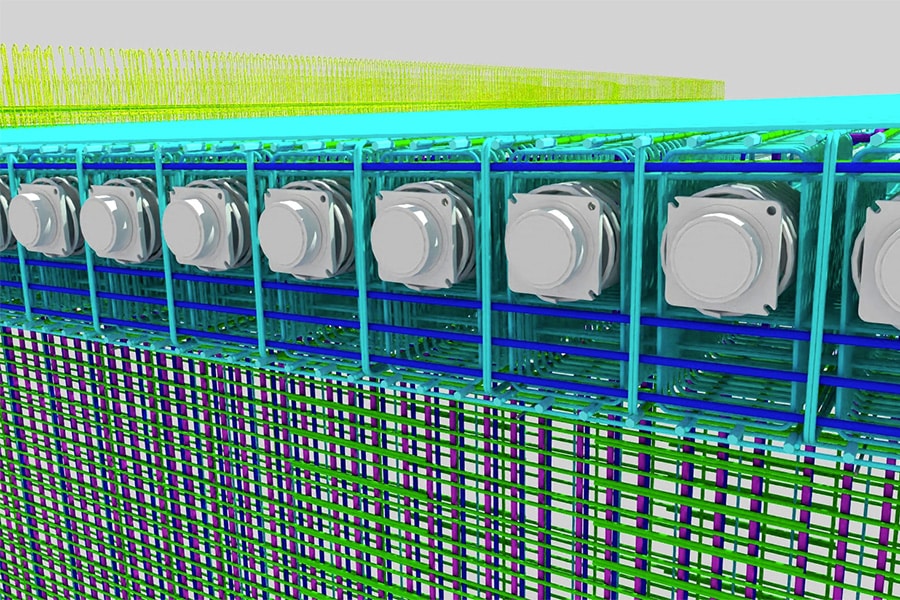

A low-emission Volvo D13J engine is at the heart of the EC530E and EC550E, but the combined fuel efficiency of up to 25% is possible thanks to the state-of-the-art electro-hydraulic system used in these machines. With intelligent electronic control, the Independent Metering Valve Technology (IMVT) provides both more precise operation and higher efficiency than a traditional mechanically coupled hydraulic system. Even better efficiency is achieved through optimization of the engine pump, which reduces engine speed while maintaining power, and an improved layout of the hydraulic lines. With all these features, the EC530E and EC550E guarantee a high level of control and efficiency for all applications.

The new system offers a range of intelligent features, including a very slow mode (useful for precise lifting and transporting) and the optional Comfort Drive Control. The Comfort Drive Control option helps reduce fatigue by allowing operators to control the machine using the joystick instead of the pedals.

Machinists can select different functions depending on the job and their own preferences. This includes boom/swing and boom/drive priority, allowing one function to take priority over another. The speed of lowering the boom can also be adjusted, giving extra control for tasks that require extra precision. Long days in the cab become less stressful thanks to boom and arm resilience reduction technology, reducing excavator shocks - a feature highly appreciated by operators.

Dig Assist machine control applications

Machinists are further assisted in their work by the optional Dig Assist applications - powered by the Volvo Co-Pilot tablet. These include 2D, In-Field Design and 3D software packages. On-board weighing is another useful feature that provides real-time bucket information (to ensure optimal filling) and records material moved by aisle, shift or day - providing valuable productivity data.

Volvo's quality attachments allow you to get the most out of your machine. The specially designed attachments - such as quick couplers, buckets, breakers and more - work in harmony with the specific features of these machines.

A second home

The Volvo Care cab is a wonderful place to spend the workday. Boarding is safe and easy thanks to bolt-on anti-slip plates and highly visible hand rails. To facilitate transport, the optional entry step and walkway can be folded down.

Once seated, operators enjoy a quiet, low-vibration and safe environment as the cab is protected by a ROPS structure that exceeds industry standards for this weight class. Furthermore, operators also enjoy exceptional visibility, an advantage that is further enhanced when a one-piece windshield is chosen. Technology also comes into play here with rear and side cameras coupled with the 360-degree Volvo Smart View option, particularly useful when working in tight spaces.

Uptime

The EC530E and EC550E are designed with high durability and maximum reliability in mind - even in heavy-duty applications. One of the smart measures is the elimination of hydraulic steering lines, reducing the number of connections required. The electrical system is also more robust thanks to connectors that meet the highest standards of protection against water ingress. Maintenance time and costs are further reduced with engine oil and filter change intervals extended to 1,000 hours and grouped filter access from the ground. Three-point access on the right side provides easy access to the AdBlue tank, which also features splash protection to prevent spills (and subsequent corrosion).

Volvo CE's portfolio of uptime services is key to ensuring long-term machine performance. Oil analysis, maintenance inspection and undercarriage inspections help keep machines in top condition, while easy-to-read reports - enabled by CareTrack telematics system - help owners keep track of productivity, fuel consumption and machine condition. For even less hassle, Volvo Uptime Centers monitor the machine and notify customers as needed.