Torrent of new machines

Brexit or not, for JCB, the world just keeps spinning. The British construction equipment manufacturer continues to innovate and share the results with that same world. Trade press from across Europe were immersed in the big load of new machines and digital tools in early June.

To start with the biggest piece of news, the Hydraload 555-210R is not only JCB's first rotary telehandler/ telescopic handler, it should above all become a gamechanger on construction sites where a lot of prefabricated elements are built or sewer pipes are installed, for example. With its 20.5 meter elevator height and a maximum lifting capacity of 5.5 tons, it can replace mobile and even fixed cranes and also do a multitude of other moving jobs. As a telescopic handler with platform, "normal" use is of course also possible. The outrigger system is very flexible: it can be used wide and narrow and has an automatic levelling system, making set-up lightning fast.

Still this year, the Hydraload 555-201R will be launched in Europe. It should become a gamechanger on construction sites where a lot of prefab elements are built.

Voor lifting work, a 2-meter-long jib can be used and attachments are automatically recognized, with setting of the correct load graph. Still this year, the Hydraload 555-201R will enter the European market, adding to the existing series of Loadall telehandlers the largest and most advanced.

Continuing with electric

The prototype of the all-electric 1.9-ton mini excavator 19C-IE is now production-ready and available from the fall. It is five times quieter than the diesel version and intended for use outdoors - in the city, for example - or in buildings and tunnels for digging or demolition work. Other electric news is the new Teletruk 30-19E. This compact telehandler is also fully electrically powered and is intended in part to replace and complement the forklift, but with some distinctive advantages. For example, its telescopic mast allows it to move pallets farther and higher: up to 1900 kg at 2 meter distances, its turning radius is minimal. With the absence of the elevator column, forward visibility is greatly improved, and its lower body now allows it to simply enter containers. Its handling also exceeds that of the forklift. Moreover, it operates quietly, both for bystanders and in the new Command Plus cab.

Lord Bamford tells the European trade press why the all-electric Teletruk 30-19E is such a big step forward.

Small news

Much small news is worth mentioning, such as both compact vibratory rollers CT160 and CT260. There is a choice of two drum widths, they have better visibility and are easy to operate. Among the dumpers, a second - 6 ton - version has been added, the 6T-1HiViz. Safety is at the same high level as the 7-ton HiViz launched last year, and visibility has been further improved, without the addition of sensors or cameras. By lowering the center of gravity, stability has been increased. In addition, it can be equipped with JCB's SiteSafe cab.

The electric mini-excavator 19C-IE shown as a prototype last year will actually become available during this year.

Cleaner diesel engines

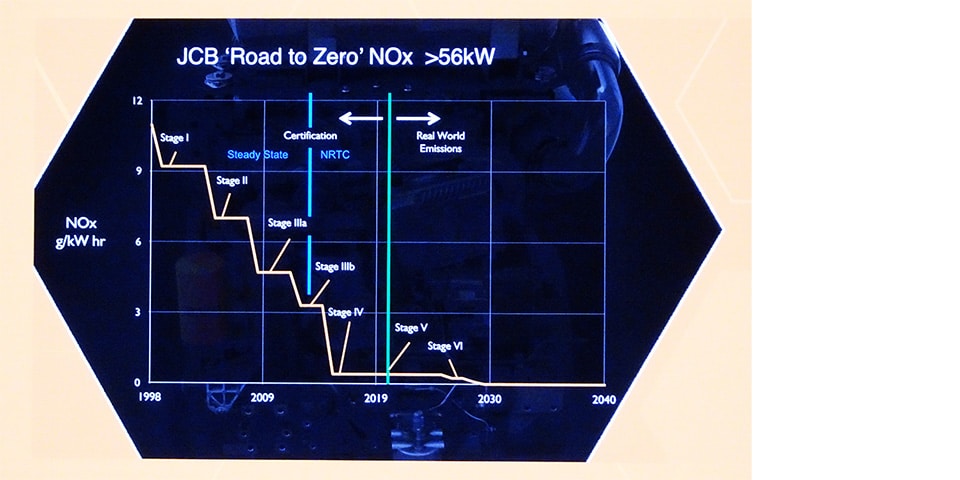

JCB maintains that the diesel engine will be used for a long time, but obviously a very clean one. A lot of work is being done on that. Its own DieselMax engine series is completely ready for Stage V and can already be found in the necessary machines. JCB calls it "almost zero emission," which is a big promise from the statement, "We want to be part of the solution, not part of the problem. JCB has already produced a quarter of a million diesel engines so the stakes are high. Incidentally, JCB is now using Cummins diesel engines for its heavier machines, it was announced.

The assembled trade press got to take a look at JCB's impressive Uptime Center at its headquarters in Uttoxeter, UK.

Digital tools

Uptime is the buzzword of 2019. At JCB, it is increasingly the starting point for customer relations. JCB machines are inherently reliable and this must be proven optimally in practice. This is possible through large-scale monitoring of machine data. At five and soon even six locations around the world, JCB has so-called Uptime Centers, from which customers are helped to keep their machines working 24/7. JCB's LifeLink system has been supplemented for that purpose with an "Operator app" (the iOS version is already there now, Android will follow later this year) and with a Fleet management system.

JCB calls the Stage V version of its own DieselMax engine "nearly zero emission," and in this chart shows how close we are to that point.