Report: from test drive to production line

It is still early when we gather at the DAF Test Track in Sint-Oedenrode for a fully catered DAF Experience, an event to which DAF sales organizations usually invite their dealers and customers. It promises to be a wonderful day, because not only will we get to drive the latest trucks (powered by diesel and electricity), we will also be given a tour of the factory and end the day with a visit to the museum.

Our experience begins on the site where every new truck undergoes its first few months of practical testing. As the test drivers greet us, another combination rumbles past. The track simulates potholes, cobblestones, bends, and slopes, conditions that together account for the equivalent of a million kilometers. Braking systems are tested to the limit here, as is the entire chassis. This is a place where no detail is left to chance. And today, we get to experience that for ourselves.

International Truck of the Year 2026

We have a wide range of latest-generation trucks at our disposal, including a series of battery-electric trucks that we put through their paces in the previous issue of GWW. Here on the test track, where we switch from a diesel truck to an identical model but with electric drive, it really becomes apparent how comfortable electric driving is and how good the electric trucks are. The quietness on board is impressive and the advanced powertrain, consisting of two separate electric motors and a central, integrated three-speed transmission, works phenomenally well. There are no noticeable gear changes. DAF's New Generation XD and XF Electric have recently been awarded the title of International Truck of the Year 2026. The jury praised the trucks for their exceptional energy efficiency, refined and powerful drivetrain, and advanced technical architecture.

More engines than trucks

From the test track, we head to Eindhoven for a tour of the factory. An impressive complex dating back to 1950, but continuously modernized. In 2024, the new engine factory was opened, where PACCAR engines are built in three shifts. Strikingly, 10 to 15 percent more engines are produced than trucks, because the engines also find their way into buses, coaches, and special vehicles.

20,000 parts

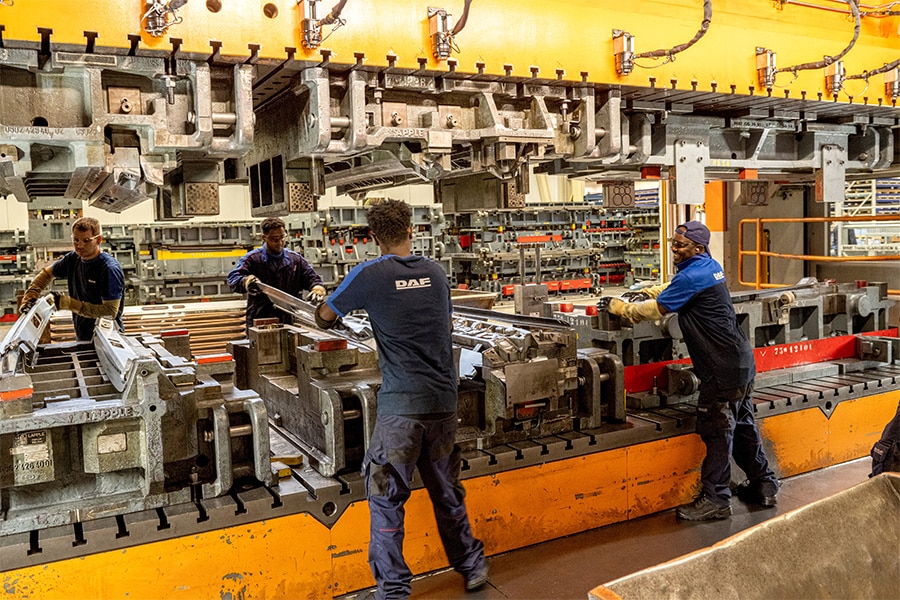

The tour continues through the sheet metal components factory, where 20,000 different parts are manufactured. The newest press dominates the hall: 11 meters high, weighing 680 tons, with a pressing force of 2,500 tons and a foundation that goes 20 meters into the ground. Thanks to four enormous dampers, the environment remains vibration-free. We also see robots welding with sparkling arcs, interspersed with skilled workers who still finish small series by hand. Exhaust pipes are cut, bent, and insulated, bumpers are glued and spot welded.

One line

Diesel and electric trucks are built side by side on the assembly line. The electric models skip the diesel steps and are temporarily moved to a separate area for the installation of batteries and high-voltage components. They eventually return for final assembly. The ambition is clear: in the future, everything must come together seamlessly on a single line.

Internal supermarket

The modular chassis, suitable for two, three, or four axles and various drive options, is delivered completely flat. Axles, sourced from Westerloo in Belgium, where the cabs are also built, are assembled before the chassis is tilted for further construction. Parts are delivered just in time from the internal ‘supermarket’: every fifteen minutes, a supply train leaves for the line. PACCAR's lean methodology is visible everywhere.

By the end of the afternoon, we reach the final stage. It is almost unbelievable that an entire truck can be assembled in just ten hours. As a brand-new truck in one of 3,000 possible colors slowly rolls out, we realize how streamlined this gigantic process is. We end the day at the DAF Museum, where the silence contrasts with the noise of the test track and the rhythm of the factory. The museum shows how far technology has come, and goes even further with its latest exhibition, ‘Design with Artificial Intelligence – Past & Future’. Highly recommended, and a fitting end to a day full of innovation, history, and craftsmanship.