Specialists deliver sustainable customization

Match choice to specific work or circumstances

To reduce emissions from construction machinery, Van den Heuvel is joining forces with three industry specialists. In cooperation with Accenda, eQuip and SDK Engineering, there is a tailor-made solution for every issue and application: retrofit (Stage V), hybrid, hydrogen or battery-electric. A fascinating conversation with the executives of four innovation partners.

Van den Heuvel - which in addition to being a dealer of the Sennebogen Crane Line also specializes in modifying and building cranes and foundation equipment - sees that customers in these niche markets are actively seeking sustainability. "We do not believe in one universal solution, nor do we pretend to have all the knowledge," states director Marc Timmerman.

"That's why we seek cooperation with parties who are specialists in electric drives, hydrogen technology or hybrid systems. Together, we can help customers choose the right route, suitable for their machine and the work to be done with it."

Practical solution

The collaboration with Accenda, eQuip and SDK Engineering arose from a shared vision: sustainable construction equipment requires technical insight, customization and knowledge of regulations. "All four companies bring in their own specialties," says Timmerman. "We integrate the systems in our workshop, provide CE marking, inspection and instructions. This is how we translate innovative technology into a workable machine on the construction site."

Together, the parties are able to offer a wide range of solutions, from retrofit to Stage V to full electrification or hydrogen. "There is no single best technique," Timmerman emphasizes. "The location, the work and the power demand determine what is technically and economically feasible. We therefore always ask the right questions of the end user before we advise."

Electric if possible

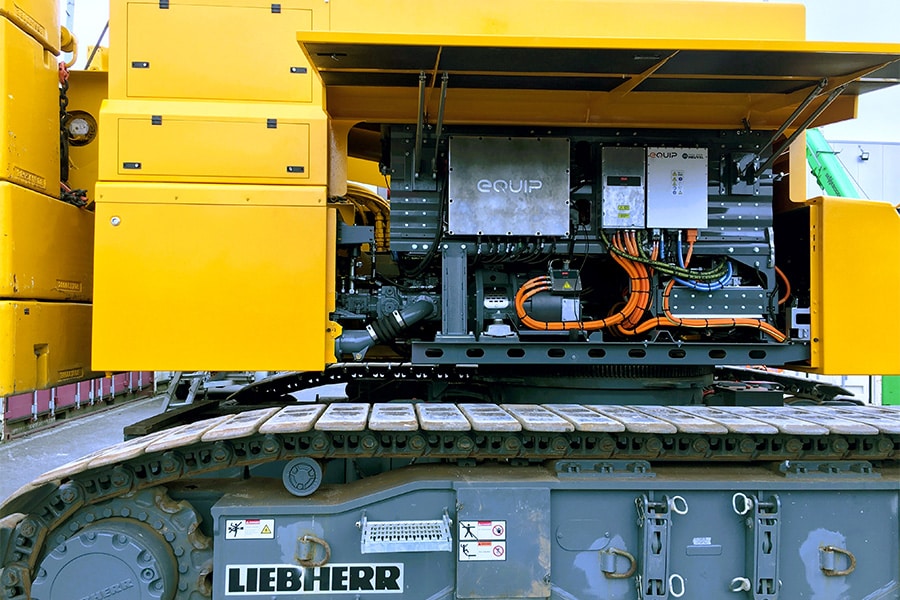

"If it can be done battery-electrically, that is the most efficient route in most cases," says Adis Bajric of eQuip, a specialist in electric drive systems for heavy machinery. "Batteries have the highest efficiency in terms of energy conversion and are reliable. But it requires a good charging infrastructure. If that is missing or the required power becomes too high, you look at alternatives to still be sustainable."

Timmerman agrees: "We have built cranes with battery packs of 200 to 400 kWh. Those can easily run for an entire working day and be charged overnight, provided you create a smart charging situation. In many cases this is quite doable, if you are willing to think differently. We firmly believe this is the future."

Hybrid and hydrogen

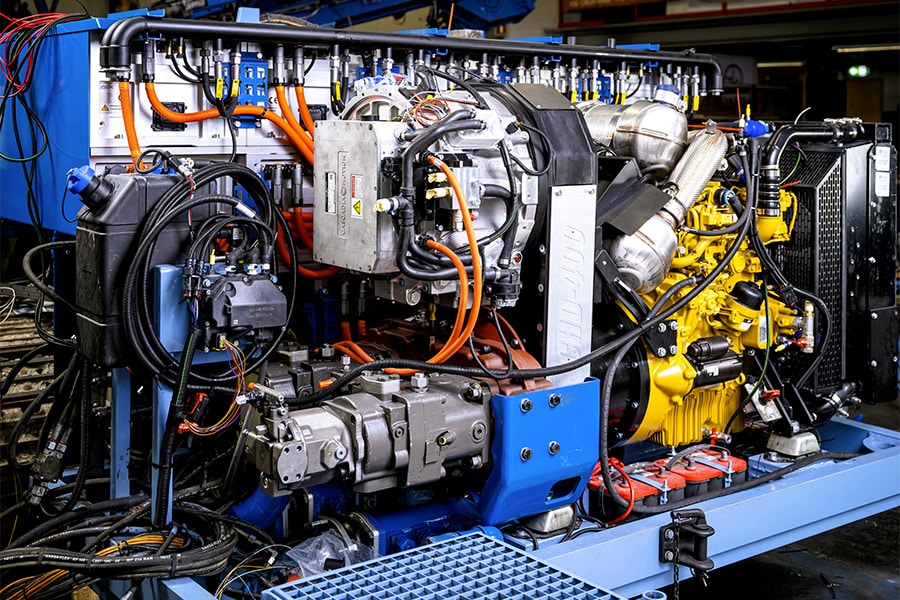

When battery capacity falls short or charging time is an issue, hybrid or hydrogen comes into the picture. SDK Engineering develops hybrid systems in which a smaller diesel power source works together with a battery pack. "Originally designed for fuel economy, but now further developed toward zero-emission," Steven de Kam explains. "With a larger battery pack, you can even operate fully electric, with the diesel engine as a backup or charger for the battery. The control is in the software."

For situations where long-term heavy work is done without charging capability, hydrogen offers an alternative. "We are betting on hydrogen fuel cells as a range extender," says Martin Seiffers of Accenda. "A hydrogen combustion engine is not completely zero-emission and has lower efficiency. With a fuel cell, you recharge the battery while working and you can provide peak power from the combined powers. So you can work with a smaller battery pack and still run a full work day."

Retrofit as an alternative

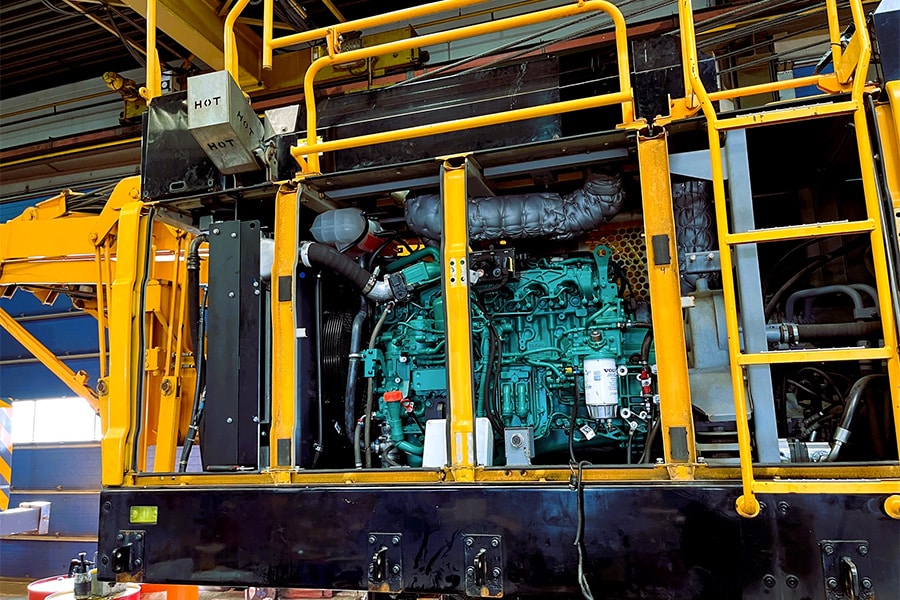

Another important pillar for Van den Heuvel is retrofit. "Foundation machines sometimes last up to 30 years," Timmerman knows. "If you upgrade such a crane from Stage II to Stage V, you already have a substantial environmental gain. Especially if you combine that with an overhaul. Retrofit is a cost-effective and sustainable solution for many companies."

Van den Heuvel has the knowledge for this in-house. "But for battery-electric, hybrid and hydrogen we rely on our partners. Accenda, eQuip and SDK have in-depth knowledge of drive systems, we of mechanical engineering, regulations and integration. In this way we strengthen each other and together come up with innovative solutions to energetically tackle the nitrogen challenges in the construction sector."

Reliable technology

Timmerman emphasizes that sustainability is more than incorporating a different system. "The whole machine has to be tuned to it. We take care of the right installation, tuning, security and link everything to the existing hydraulics plus controls. In the process, the system must also be robust. The end user must be able to trust that it just works and will continue to work."

According to Seiffers of Accenda, which is behind the creation of the first 100% clean hydrogen-powered excavator for Mourik Infra, a realistic approach is crucial. "Zero-emission equipment requires a different infrastructure as well as a different mindset. You can't do everything the way you're used to. But you don't have to. If you explain it well and use the right components, it's perfectly feasible." De Kam (SDK): "The technology is reliable, provided you apply it properly."

Fear of unknown

According to Bajric (eQuip), there are many misunderstandings surrounding the safety and reliability of zero-emission equipment: "This is mainly fear of the unknown, dangers you don't see. Many malfunctions stem from ignorance. Think of a muddy plug that goes into the machine without pardon or a construction cabinet that is half in water. If the battery then doesn't charge, it's not because of the technology but because of the circumstances."

The flywheel of sustainability is unstoppable, the four partners agree. "It may be going slower than desired, but it is an irreversible development," Seiffers judges. Bajric adds: "We are at the beginning of a technological change, just like the transition from horse and carriage to internal combustion engine. That didn't go smoothly either, with a gas station on every street corner." "At best, the customer who invests now is a bit ahead of the game, but he is taking the right step," says Timmerman.

One vision, multiple routes

The strength of the cooperation lies in combining specialties, always with one goal in mind: a reliable, safe and sustainable solution for the field. "Every customer, machine or application requires customization," Timmerman knows. "This is precisely why we join forces, together with the end user. Because only together do you really get ahead."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Van den Heuvel.

Contact opnemen

Contact opnemen