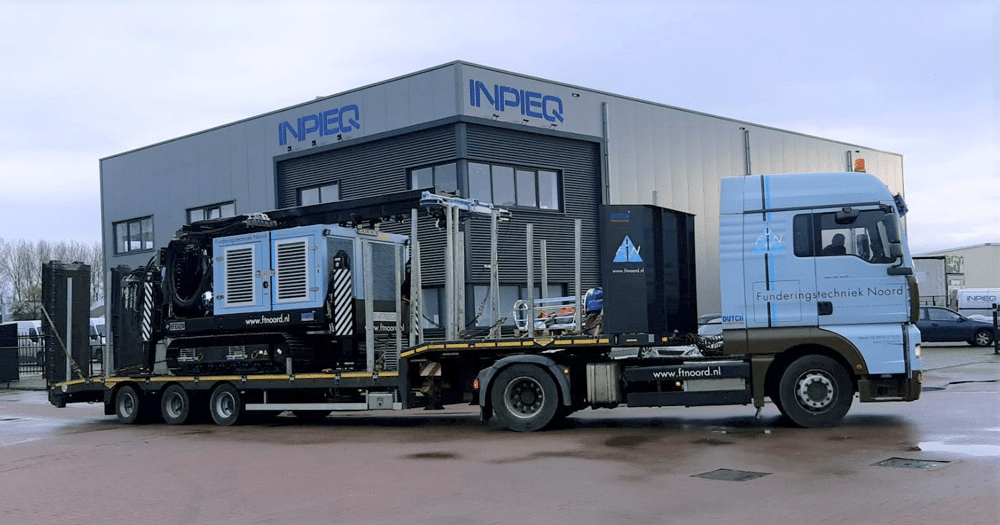

Inpieq ramping up with customer-specific solutions

This is easier to achieve within one sector than somewhere else. For example, foundation work usually requires the use of heavier equipment, which cannot easily be powered by a battery pack. Nevertheless, even in this close-knit world, Frank van Deursen is regularly talking about electrification. The owner of Inpieq is getting more and more requests for electric foundation machines. "That's very interesting, but also a huge challenge. We now have a request for a larger machine with a 350 kW electric motor, but that comes at quite a cost. Then the question is: is this profitable?"

Inpieq therefore sees hybrid foundation equipment as a good intermediate solution, of course in combination with a Stage V diesel engine. "Then such a machine falls 10 to 15% more expensive, which is manageable. If a piling or drilling rig is not yet due for replacement, we can adapt it to the latest emission values if necessary," says Van Deursen, who does point out another problem. "Electrical equipment up to about 65 kW of power can still be connected to the mains, but above that you soon have to deal with power current. As a result, there will be increasingly stringent requirements for clients in terms of power supply on the construction site."

CLEAR REVERSAL

Van Deursen therefore speaks of an interesting period, in which Inpieq is certainly not sitting still. A clear turnaround was made two years back, with a greater emphasis on service, flexibility and innovation, leading to the new construction of customer-specific machines. "We want to work closely together and listen to what the market wants. As a result, Inpieq is increasingly developing into a one-stop-shop, with its own grout unit, pile registration system and all related services in addition to foundation equipment. As a result, the customer only needs to look for a pipe or drill body."

The Steenberg-based company provides a complete range of services to relieve customers of their worries. Consider, for example, combining maintenance with the periodic inspection of stationary equipment. Van Deursen notices that the diesel engine is disappearing from stationary machines because of the choice for electric. For example, Inpieq supplies a unit on batteries and with 45 kW of hydraulic power. This can be used flexibly to drive a foundation machine or grout unit. The interest in this concept is high due to the many foundation repairs in large cities. "We are noticing a change from piling to grout-injection drilling. Although the pile is slightly more expensive, it is vibration-free, making it certainly interesting in densely built-up areas."

MODULAR CONSTRUCTION

With the IFD-2.0, Inpieq has developed a foundation machine for this work that is as compact as it is powerful and flexible, delivering a maximum drilling torque of 20 kNm over the entire leader and powered by an electric power pack on tracks. Since modular construction based on one type of upper structure is used, a limited lead time can be guaranteed. By varying mast, tracks and support legs, this principle can be applied for both piling and drilling lines. "With this concept we can go in all directions, which makes it price interesting. Build in a free-fall winch and a piling rig is created." This idea is also reflected in its bigger brother IFD-20, with a maximum drilling torque of 200 kNm.

With the DLS Registration System, developed entirely in-house, Inpieq proves that data management (read: less paperwork) goes hand in hand with ease of operation for the operator. The IGP grout mixing and pumping unit and IFD drilling rig are also a feat of technical ingenuity. What else is in the pipeline? "We want to expand the hydraulic drilling and piling series to four or five models and are working on a range of three grout unit models. Right now, the IGP-300 with a 300-liter grout pump in a very compact frame is the largest model in this line."