The future-proof (sound) screen is here, thanks to clever engineering!

Four years ago five gentlemen knocked on Hennie Peek's door with a revolutionary idea for a new noise barrier, Wacerwall. The idea was ripe for further development and implementation, so where better to turn than to Peek Bouw & Infra? Nowhere, because the company has more than earned its spurs in the world of noise barriers.

Meanwhile, Peek Bouw & Infra is a fifth shareholder in Wacerwall. We speak with Hennie Peek and Jochem van Vliet, about the development of an idea with major implications for the way we will be looking at (sound) screens in the infrastructure sector in the near future.

Green and fresh: Wacerwall with vegetation.

From prefabricated to absolutely customized

"When the idea was presented to us, it worked on paper. We ran tests and, based on that, developed the product into what it is today," Van Vliet opens the conversation. What does Wacerwall consist of? "The materials used in the screens are EPS and concrete," Van Vliet explains. Peek adds, "We started by spraying concrete onto EPS. So the concrete is like a 'shell' around the EPS. That spray work was somewhat erratic, so we switched to pouring with self-compacting concrete around the EPS. The wall panels we make with this are quick to install, lightweight, completely modular and available in various heights. So applicable within any project where good shielding from sight, sound or light is needed."

Test setup planted Wacerall, RWS.

Wacerwall is offered in several ways: without foundation, as prefabricated elements or with foundation, to be built on site. "Wacerwall can be used as a permanent solution, or as a temporary solution. We also see Wacerwall applied in art objects," Peek says. "The bulk of our deliveries consist of foundation-free elements. Ideal, because you don't have to go into the ground, everything can be put down on a 'stand alone' basis. And that completely modular, so if you do need to be under the Wacerwall to dig up a cable somewhere, the corresponding element can simply be removed from the row, to be placed back later." Customization, with foundation is also interesting, we learn. Van Vliet explains: "In principle, with Wacerwall everything can be customized, making it a nice solution for railroads, provincial roads, municipal roads et cetera. Add to that the fact that it is a sustainable product with impressive performance -the tests don't lie- and you will understand why parties like RWS have already approached us."

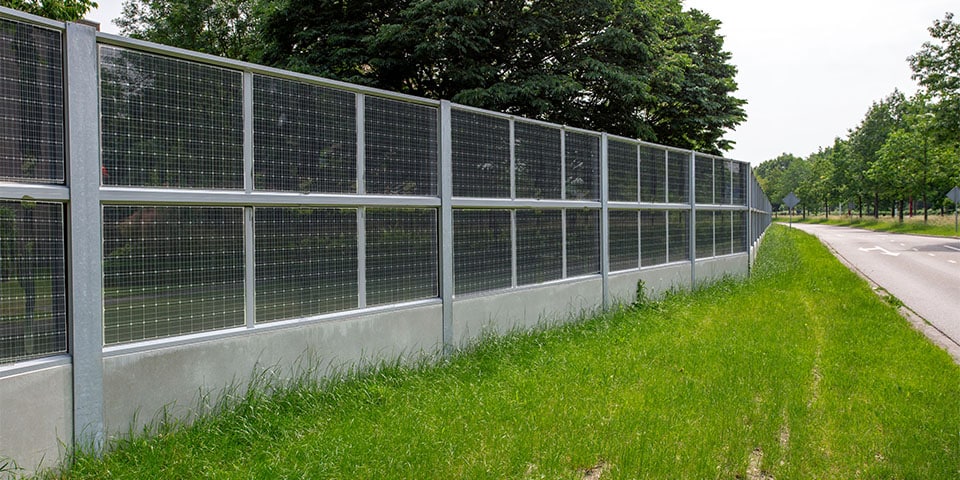

Wacerwall with solar panels, Nieuwegein.

Looking forward to tomorrow

Wacerwall is a future-proof product. Van Vliet notes, "It is 100% recyclable. Also, components can be reused perfectly well, all prefabricated parts of the foundationless screens are demountable and relocatable." Peek adds: "The best part is that the modular screens can simply be picked up in their entirety to be deployed elsewhere immediately ready for use. How circular do you want it to be?" It can be substantiated that the lifespan of Wacerwall is at least 50 years. "With that we comply with the GCW 2012 (guidelines for noise-reducing constructions along roads) rules. And as icing on the cake, we can announce that Wacerwall is the only screen included in RWS's DuboCalc. We're quite proud of that," says Van Vliet. With custom-made screens, the CO2 reduction up to 70 % and a 60% lower MKI score is possible compared to a modular RWS screen.

The development of Wacerwall is not standing still. "For example, Wacerwall is available with a special coating that breaks down the harmful substances in exhaust fumes," Van Vliet outlines. "We are currently running a pilot for RWS with planting for the benefit of greenery on structures on the A12 ring road near Utrecht. To top it all off, we are currently running a trial to apply solar panels to Wacerwall. With the increasing demand for energy-neutral or energy-positive roads, this is certainly interesting for the near future. We are taking this a step further and also testing panels in which the solar panels are fully integrated." In conclusion, Peek says, "All nice and innovative extras on a mature product, which is through its teething stages. Anyone who wants to can start making meters with Wacerwall today."