Every bin is hit with new iXE3 option

The advanced 3D excavator control solution iXE3 now offers partial or full automation of boom, bucket, tilt bucket and even the tilt rotator, or rotary tilt. The accompanying "battle cry" makes the major advantages clear in three words: "Every bucket hits the mark.

"Get the most out of your machine with the new semi-automatic Leica iXE3 machine control for excavators." Thus the time-saving mode of operation is aptly described.

Leica Geosystems offers several tools to further increase excavator productivity. They all boil down to the extensive automation of crucial functions. We already knew the iXE

CoPilot, which automates the turning and rotation functions of a rotary tool. Also of interest is Leica TRM, the automatic tool recognition that ensures, that the correct bin is automatically selected in the machine control solution.

Complex work

Now a third and not the least functionality is being added: semi-automatic control of boom and attached implements, including the rotary attachment. This gives the operator all the room he needs to perform complex excavation work, such as making slopes and digging trenches, both faster and more accurately. And since time is money here as well, this will be music to the ears not only of the operator, but certainly also his employer and client. Moreover, this simplification of excavator operation reduces operator fatigue when working long days, fewer (costly) errors are made, and even less experienced operators can still achieve an optimal end result due to the semi-automatic functionality. The new semi-automatic machine control will also be available as a surface mount kit for existing machines.

Future of digging indication

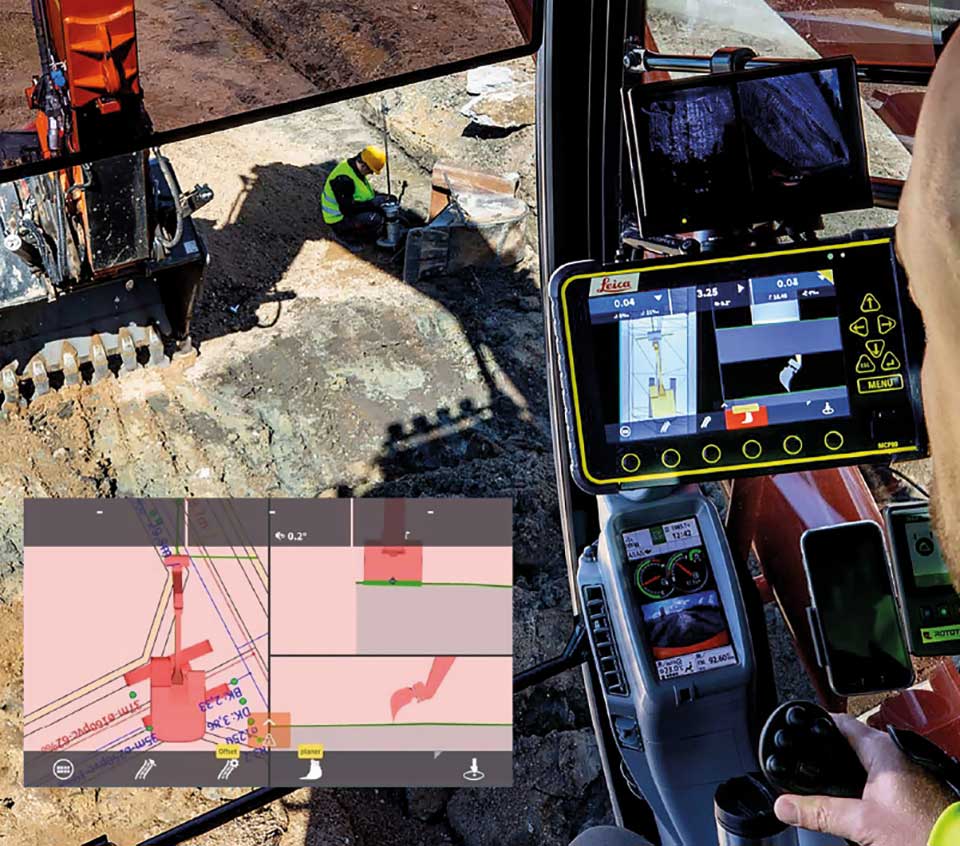

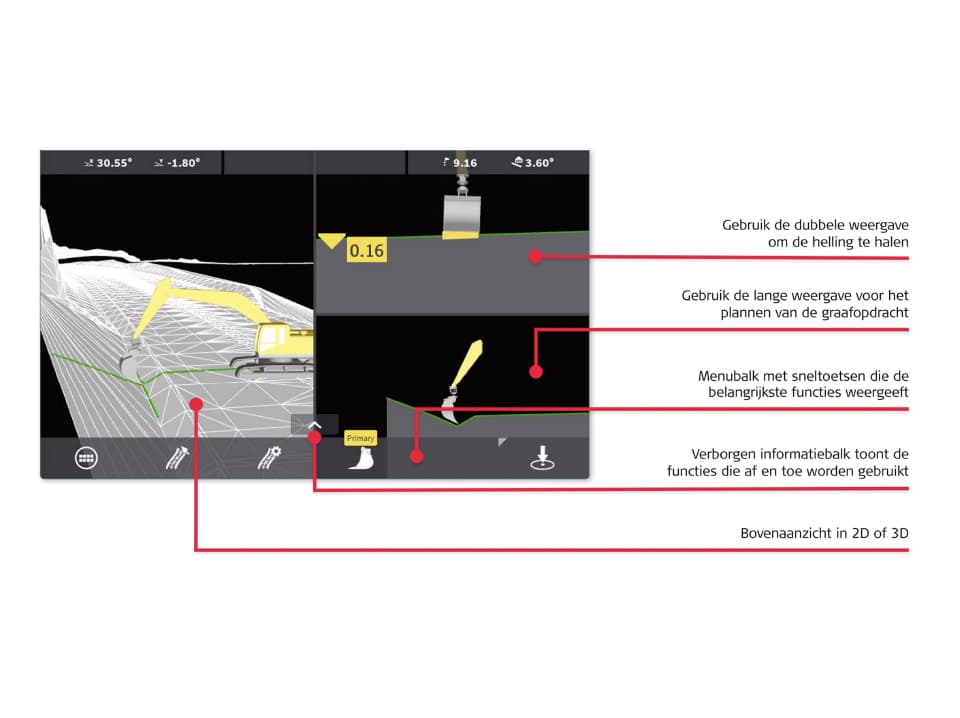

The new semi-automatic machine control is being added by Leica Geosystems as an option to the iCON iXE3 platform. This gives machine operators for all types and brands of (excavating) machines one platform with a simple and intuitive user interface. The display has an efficient menu structure with icons, giving the operator quick access to the functions he needs to select for the desired semi-automatic workflow. Leica Geosystems rightly calls the iXE3 platform "the future of excavation indication," in part because of its high accuracy.

The iXE3 machine control solution guides the operator using reference models and satellite navigation: the 3D-GNSS (Global Navigation Satellite System). Design information and real-time up/down indication are displayed on the screen in the cab, making it possible to work very quickly at the desired height. According to Leica Geosystems, the solution "increases operating time and operator satisfaction, while increasing safety and productivity."

It doesn't get any easier

The cable-free MCP80 control panel has an efficient menu structure with icons and it can handle all 3D applications in earth, road and hydraulic engineering. This gives the operator quick access to the functions he needs to select for the desired semi-automatic workflow. The control panel has a large touch screen with backlit buttons. It is easy to adjust to one's own settings and it is easy to carry from one machine to another. The docking station of the MDS series allows the operator to easily carry the panel from one machine to another. The most recent calibration values and hydraulic parameters are stored in the process. Once placed in the docking station of the other machine, the operator can simply turn the start key to continue his work.