Durable rubber level crossings at Amstelveen line sidings

Customized solution for every railroad construction

The renovated Amstelveen Line will have an entirely new stabling area for streetcars in the Legmeerpolder. In addition to stabling areas for the rolling stock, there will also be locations for minor maintenance on the streetcars, among other things. The sidings will be accessible to personnel thanks to a large number of solid rubber level crossing paths, sustainably made from 100 percent recycled car tires.

Depot reference, United Kingdom.

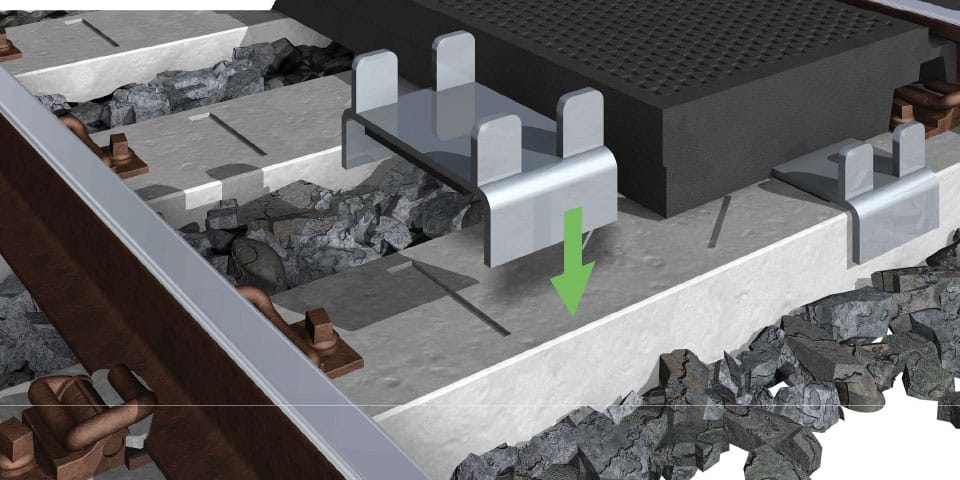

The complete rubber level crossings are supplied by Alom, engineer and supplier of railroad materials. The crossing supplied by British company Rosehill Rail manufactured level crossing system has many advantages, states Alom director Mark van den Rijen. ''The solid rubber level crossing panels can be installed quickly and efficiently. For the installation of the panels with a length of 1.80 meters and a weight of about 200 - 250 kilos, you do not need large cranes. Two panels, thanks to so-called lifting pins, can be lowered simultaneously into a roof profile between the rails. Panels can also be removed again separately and easily with these lifting pins for track maintenance and inspection purposes, without having to dismantle the entire level crossing.''

Depending on the use of the transition, level crossings can be applied in different strengths. The "baseplate" is for lighter use by, for example, pedestrians and cyclists. These panels support the sleepers and are connected together at the bottom with steel plates. When heavy traffic uses the crossing, the Rosehill Rail 'Rodded' system is used. These panels have an integrated steel frame connected together with bolts protected by rubber cover plates

The baseplate for lighter traffic is coupled with a steel frame at the bottom.

The level crossing panels are produced in a press using an innovative and environmentally friendly "Cold Curing" method to ensure a long service life. Van den Rijen: ''These level crossings are wear-resistant, extremely low-maintenance and can withstand many years of heavy traffic and all climate conditions.''

Overpasses can be customized for switches or can be cut for other special rail infrastructure. Alom is developing a laying plan for such specific situations. ''Rosehill level crossings can also be laid in curves. We design a custom solution for each rail construction in question,'' Van den Rijen states. ''At the Amstelveen Line sidings, the panels are also applied around the sand filling installation and quick service point.''

According to Van den Rijen, Rosehill's system offers a solution because train traffic in the Netherlands will increase in the coming years. ''Then it is important that rail availability also increases. The Netherlands has a total of some 2,500 level crossings. 1800 of these are located on public roads and are public crossings. Shortening out-of-service periods for track maintenance is an important element in this.''

''You can think of Alom as the railroad industry's all-encompassing supermarket,'' Van den Rijen believes. ''To stay in that equation: you can come to us for a crate of Heineken all the way through to delicacies and all kinds of special ingredients. But we also like to think along, we have added value for our customers. We can offer customization for specific requests from our customers. We (co)engineer our own rail systems, what we come up with we can also deliver. For example, we developed our own rail system for the North-South line in Amsterdam. We are extremely proud of that.''