Smart sliding system for new bridges at the Darmstadt interchange

One of Germany's most important traffic arteries, the junction between the A5 and A67 near Darmstadt, between Mannheim and Frankfurt, is in need of renovation. The four existing bridges showed defects in load-bearing capacity and have now been completely demolished and replaced by four new bridges, including additional lanes. The new bridges have an architecturally attractive design. In order to install the new bridges with as little disruption to traffic as possible, a special sliding system was chosen.

The company Eiffage Infra Süd-West (part of Eiffage) is the main contractor for the redevelopment of the thoroughfare. The Belgian company Iemants, also part of Eiffage, carried out the manufacture and assembly of new steel bridges. The engineering firm Iv collaborated on the design.

Design of the main bridge

The main bridge consists of two adjacent, virtually identical bridges and is also known as the Zentralbauwerk. The basic design for these bridges was provided by the client. Iemants assessed the accompanying sliding concept and developed it further to ensure that the loads during assembly remained below the permissible values.

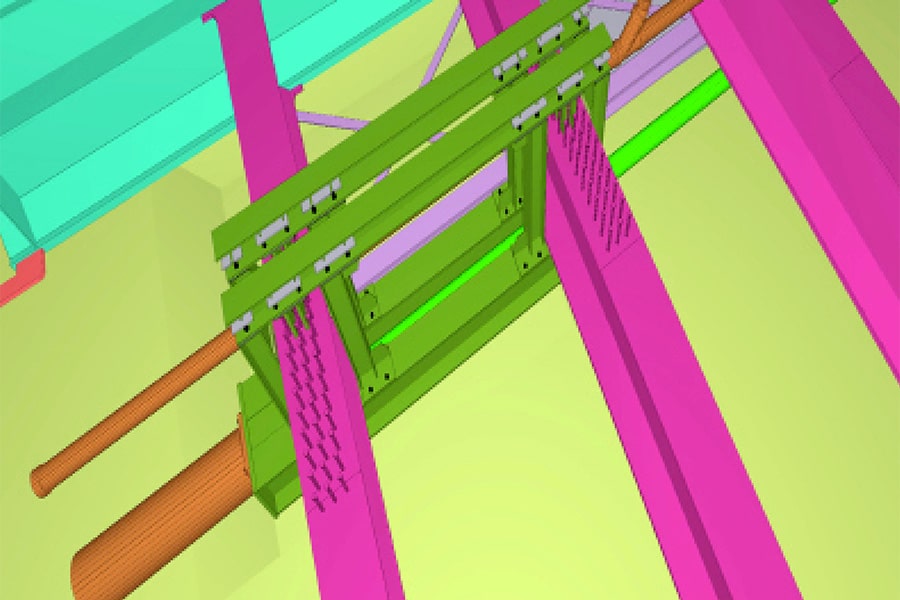

The new bridge has a very slender design, which means that the force transfer to the body plates from the temporary supports is critical. The methodology had to be revised in order to achieve better force transfer. Iemants devised and implemented a new design for the sliding shoes for this purpose. This resulted in a sound and manageable implementation.

Design description

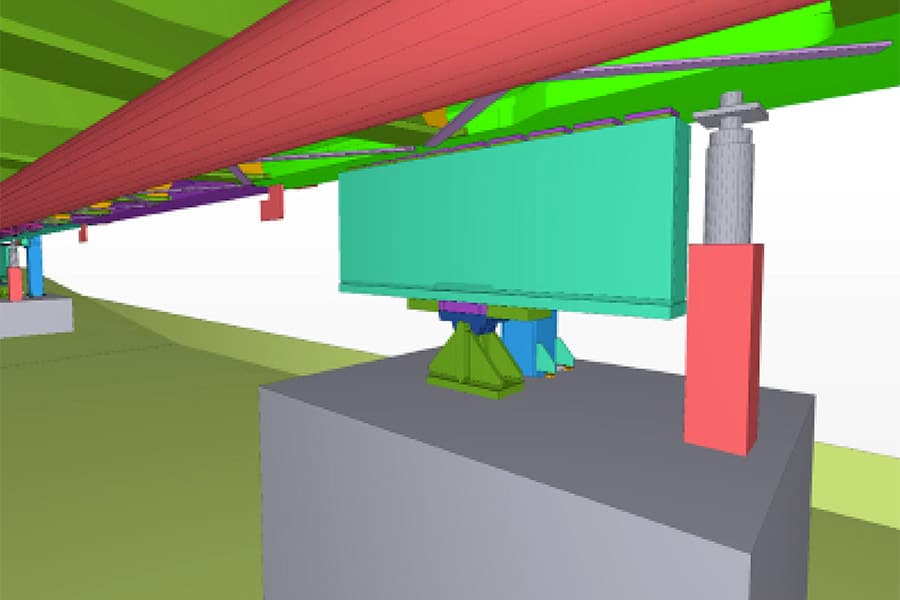

The new bridge complex meets the highest German standards and is characterized by a modern look, with striking color accents. The interior of the Zentralbauwerk features strips in various colors, from green to purple, adding a unique aspect to the bridge.

A single bridge consists of two large continuous slab girders spanning multiple supports. The height of the slab girders follows the moment distribution. Cross girders with dowels are placed between the main girders. A concrete deck is poured over the cross girders, creating a steel-concrete composite deck. A single bridge is approximately 16 meters wide and has a length of approximately 160 meters, with a main span of 72 meters and two side spans of 38 meters.

A complex retractable system

A major challenge was shifting the bridges. Custom-made sliding shoes with bearings, load distribution plates, and a sliding surface made of polished stainless steel and polytetrafluoroethylene (PTFE) were developed for this purpose. This system ensured balanced and predictable friction and movement. In collaboration with Iemants, Trelleborg developed special rubber blocks that were incorporated into the sliding shoes. These blocks enabled flexible support, guaranteeing correct load distribution.

Iv collaborated on the detailed development of the retraction system, which consists of a drive system with cables and a support system with sliding shoes. In addition, Iv carried out structural testing of the bridge during the various construction phases of assembly. Based on this, adjustments and optimizations were made.

The bridge was pulled from the front construction site using cables and a support frame over specially developed sliding shoes. Because an existing highway had to be crossed, finding sufficient temporary support points and space was a challenge. Although each bridge ultimately has three main spans, additional intermediate support points in the main spans were used for the sliding process. By making clever use of abutments and taking these into account in the design, sufficient space was found to absorb the launching and support forces.

The pull cables have a fixed point at the abutment, where a pull frame has been developed. A jacking mechanism has been incorporated into the cross girders at the rear of the bridge, which can pull on the cable. This allows the bridge to pull itself across the road, as it were. The bridge crosses the highway at an angle and has a skewed connection at the abutments. A fairly large end cross girder has also been provided here.

The bridge has a different span each time it is moved and also cantilevers out as it moves. This causes the bridge deck to bend at the front. A temporary beak has been mounted at the front of the bridge. The beak can absorb this deflection and, as it were, lift the bridge back onto the next support.

Because the bridge deforms and undergoes vertical angular rotation when passing the temporary support points, the sliding shoes have been designed to be spring-loaded and hinged, enabling them to follow the curvature of the bridge.

The bridge is also equipped with jacks near the sliding shoes. These can be used to lift the bridge so that inspections and any repairs to the sliding surfaces can be carried out. Just like a sled on ice, the bridge can also slide sideways when moving. To prevent this, lateral supports have been installed, which also include a jacking mechanism to push the bridge into the correct position. At the final support points, the bearings have been extended and the bridge is wider in this area. The lateral supports must be able to pass this widening. To this end, they can be partially dismantled. The sliding surfaces of the lateral supports can also hinge, so that the bridge does not get stuck when there is a small horizontal angle rotation.

Ensuring that implementation remains manageable and secure

The sliding shoes worked so well during installation that the process was quick and smooth, with no wear and tear. Although the design seems simple, it took a lot of creativity and technical ingenuity to carefully calculate the many installation steps and ensure the safety and manageability of the project at every stage. The bridges have now been completed and handed over.