Forecast specialist delivers craftsmanship on new viaduct

For the realization of the Princess Alexia Viaduct, De Vries Voorspantechnieken is supplying all anchoring and prestressing systems needed to constructively reinforce the bridge deck. An intensive job given the large quantities, the tight pace and all that in the middle of the winter season that brings extra risks. Yet it is precisely this type of technically challenging project that fits perfectly with De Vries' expertise.

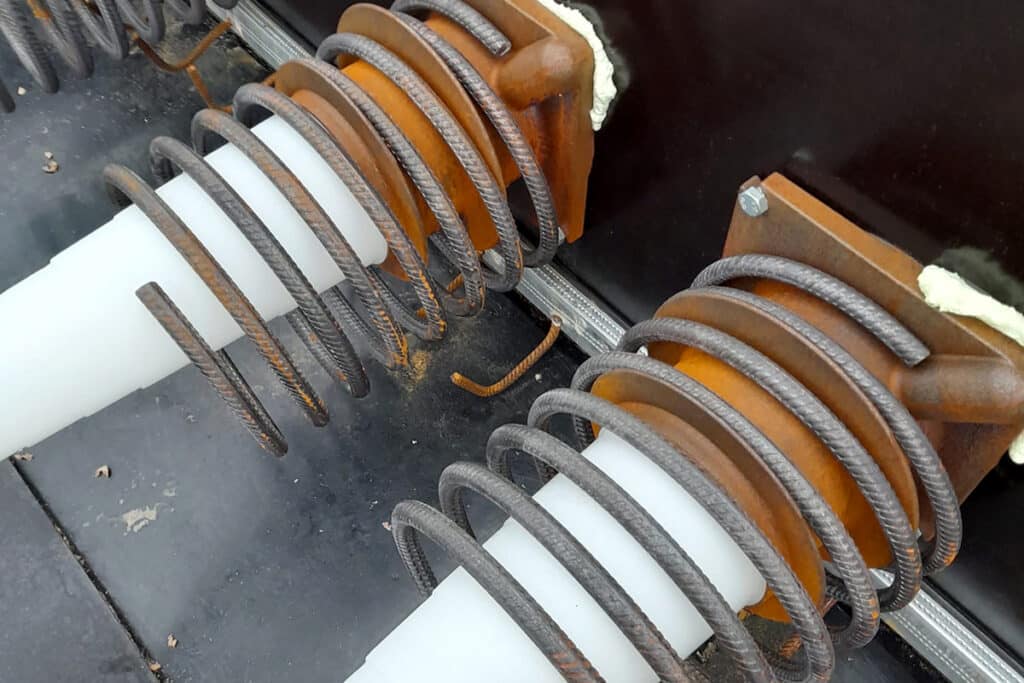

The scope includes the supply and installation of all prestressing systems in the deck of the viaduct, begins Paul Posthoorn, business manager of De Vries Voorspantechnieken. “Our work is closely intertwined with that of BAM Infra Nederland, with whom we maintain a long-standing partnership.” The casing tubes and reinforcement were installed by the construction company. It involves 66 prestressing tubes about 40 meters long. “The casing tubes of ribbed sheet steel with an inner diameter of 100 millimeters were delivered in lengths of 6 meters and coupled to full channel lengths,” explains Luuk Hendriks, work planner at De Vries Voorspantechnieken. “Although in this contract the braider takes the pipes with him, we check in advance of the pouring of the deck that both pipes and anchoring systems are correctly installed.”

From shrink preload to end preload

De Vries assisted BAM in the preparation to arrive at the most optimal design. “After all, the prestressing and anchoring systems are an integral part of the overall reinforcement configuration,” says Hendriks. “Just prior to the concrete pour of the deck on Dec. 13, we inserted the strands of 15.7 mm prestressing steel. “A total of about 80 tons of steel went in. On Monday, December 15, we brought in the 66 strands at about 20 percent prestressing strength. This is to prevent cracking. In the second week of January, the final prestressing will follow, where the cables will be fully tensioned. Then the channels will be finished, with the cable ends ground off, the tensioning heads sealed and the channels injected with a ready-to-use high-quality injection mortar. All this work is carried out by our own teams, guaranteeing consistent quality.”

Craftsmanship

The biggest challenge with this project, according to Posthoorn, is in the combination of numbers and schedule: 66 cables in a short time on a very wide bridge deck. ‘In addition, the time of year plays a role. Injection mortars may not be applied below 5 degrees Celsius and night frost can throw a spanner in the works. There are management measures, such as insulation or temporary heating, to deal with this.“

Versatile

De Vries Voorspantechnieken holds licenses from both Tensa International and BBR VT International. “Whereas most competitors have only one license, we deliberately choose two complementary systems,” says Posthoorn. “This allows us to deploy the optimal system for each project, fully tailored to the customer's requirements. This flexibility and degree of customization set us apart in the market. Just like our high level of craftsmanship, by the way, with highly trained pre-stressing engineers with many decades of

of experience.”

The expertise in longitudinal prestressing, transverse prestressing in prefabricated box girders, tube systems, ring prestressing, external prestressing and floor prestressing makes the De Vries Prestressing Systems rightfully a versatile specialist.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met De Vries Werkendam.

Contact opnemen

Contact opnemen