Integration testing for Spijkenisse Bridge renovation successfully completed

In order to continue to safely control, operate and monitor the Spijkenisse Bridge over the Oude Maas, all electrical installations and systems are being renewed. Thanks to extensive testing of the controls, virtual commissioning and the application of the automation standard 3B-Building Block, the project risks are minimized. The integral Factory Acceptance Test (iFAT) recently took place at Yunex Traffic in Zoetermeer. A milestone in this challenging project for which VSE supplies the drives for the bridge traps.

The Spijkenisse Bridge is an important link for road traffic and shipping. It has two bridge traps and opens about 7,000 times a year to allow large ships to pass. Spare parts for the decades-old traffic and bridge technical equipment and the controls of the bridge falls are hardly available anymore. Failures can no longer always be solved quickly. The combination Yunex Traffic - Heijmans won the European tender from Rijkswaterstaat (RWS) to renew the technical systems and installations. Minimizing disruption, expert transition management and optimizing system integration were important EMVI criteria. The project officially started in September 2023.

3B Building block: high availability

The bridge will be equipped with the 3B Building Block, an automation standard developed by Yunex Traffic on behalf of RWS to control, operate and monitor (3B) all dynamic functions in the bridge. These include signaling and barriers. Gradually, seven bridges in the South Holland region are being equipped with this standard. This makes it less complex and more efficient for RWS to manage the bridges, which contributes to high availability and thus smooth traffic flow.

Environmental Management

For the renovation of the Spijkenisse Bridge, a large team of environmental managers was set up. "We are therefore dealing with many stakeholders," says Patrick Hoet, employed by Heijmans and project manager of the combination. "Among them are two municipalities, Province of South Holland, Port of Rotterdam Authority, road and shipping traffic and direct local residents and associations. The ports of Dordrecht and Moerdijk also depend on this bridge. All noses need to be in the same direction and many permits need to be arranged."

Always one hef available

The logistical challenge is also great. Nothing less than "the brain" of the bridge is being replaced! Robbert Geers, technical advisor at RWS, explains how this can take place without completely halting shipping. "The current electrical systems and installations are in the middle pillar of the bridge, the new installations will be housed in the two outer pillars. This allows us to build the new installations in parallel. Also, the bridge has two lifting sections. This allows us to convert one and continue operating with the other lift. In the summer vacations, when there is little commercial traffic, we convert the lift on the Hoogvliet side and in the autumn vacations the lift on the Spijkenisse side."

Collaboration Day

RWS and the combination used a collaboration day from the start to discuss differences in interpretation of requirements, among other things. Patrick Hoet: "In the beginning, contract partners are often separate islands between which bridges have to be built. As the first designs came and we talked about solutions, the cooperation became easier and easier."

Drive

VSE was involved by the combination Yunex Traffic - Heijmans halfway through the Final Design as a partner for driving the lifts. "Given the current labor shortage, we don't have enough engineers for that ourselves," says René Prins, technical manager of Yunex Traffic and of the combination. "Siemens supplies the components for the drive and VSE, as a partner of Siemens, has a lot of experience with that. We got to know each other in 2023 at the Energy Trade Fair and immediately had a click. They knew exactly what they were talking about and were able to change gears quickly."

Specialist work

Radboud van Dusseldorp, commercial manager at VSE: "Our engineers are specialists in building high-end control solutions, and that is exactly what they enjoy doing. So a challenge like the Spijkenisse Bridge is something we enjoy taking on! We like the cooperation with Yunex Traffic very much." René Prins agrees, "We sit at the table as technicians among ourselves and want to work together more often in the future. I'd rather invest a little more in a partner who knows what he's doing than having to solve problems myself afterwards."

Siemens Technology

The hoists' winches are driven by SIMOTICS 1-PH8 short-circuit anchor motors with SINAMICS S120 variable speed drives. For calculating, controlling and monitoring the motion profile, VSE used a Siemens Drive Controller and for safe control of the system a Siemens Safety Controller. ′

Testing and simulation

In order to limit disruption and meet the established timeframes, all installations and systems are designed and extensively tested beforehand in the factory using simulation software, BIM and 3D models. Patrick Hoet: "A renovation while the store remains open always involves restrictions. For example, we cannot simply turn off a barrier for a test, not to mention the limited space available to do the replacement work." Robbert Geers: "We don't want to encounter any residual issues during the Site Acceptance Test (SAT) in the field that could jeopardize the delivery date. That's why we test as much as possible in the factory. This is also faster than on-site testing."

Minimizing risks

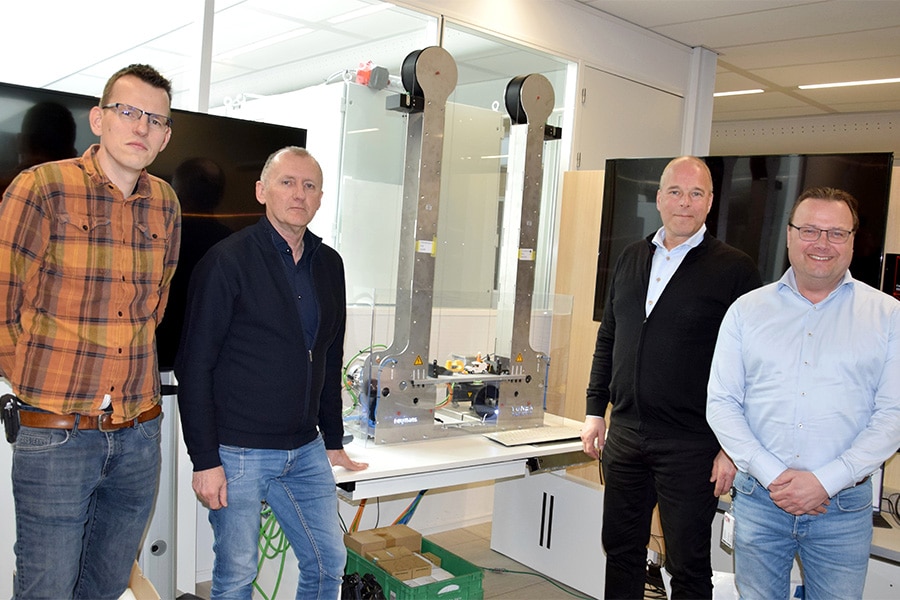

VSE used design technology NX MCD and SIMIT from Siemens to simulate and virtually commission the drive system. During the iFAT, the control boxes for the first bridge trap were linked to a scale model of the bridge. From then on, the project became very tangible for all involved. "The beauty of such a scale model is that you see it move," said René Prins. "It is an investment, but you need it in order to do extensive testing without running the risks you would face in the field. Working with simulations and models is safe, time- and cost-efficient." Radboud van Dusseldorp: "After testing the control boxes for the first lift on a scale model, we only needed to test the software for the second lift virtually."

Integration Testing

For the iFAT at Yunex Traffic, all systems were linked: the drive and the traffic and bridge technical installations (cameras, barriers, lighting, etc.). Robbert Geers: "A model is nice, but when you tie together the hardware that will also be outside, you get even closer to the real situation." After a successful iFAT, the contract partners can work confidently toward the physical conversion. The mechanics from VSE who connected the cabinets inside will also do the same outside so that everything runs smoothly. Meanwhile, the eastern lift of the Spijkenisse Bridge, on the Hoogvliet side, has been disconnected from the existing systems and will be connected to the new systems during the summer vacations. In the meantime, the lift will remain in the low position so that road traffic can still drive over it. The western lift will be converted during the fall break. Simultaneously with the installation of the new systems, the steel cables and electric motors used to lift the lifts will also be renewed.

Peak shaving and emergency power

An additional power supply will be built on the Hoogvliet side so that the bridge will be less sensitive to power failures. Initially, the idea was to use UltraCaps from Siemens as a power supply, but it was ultimately decided to use them only for peak shaving, the smoothing of energy absorbed and returned. "UltraCaps are fairly new and are now being used on large bridges for the first time," said Robbert Geers. "VSE advised us to use the UltraCaps only for peak shaving and suggested alternatives for the emergency power supply. This made the installation more robust and improved our availability."

Bridge over the North

In addition to the Spijkenisse Bridge, the tender includes the renovation of the Bridge over the North. By having the same team do two bridges in a row, RWS wants to achieve more efficiency. Robbert Geers: "In the beginning you have to get used to each other, but once a bond has been built, processes go faster and faster. About 30 to 40 percent of the efficiency is in team retention for the Bridge over North." Patrick Hoet: "By now we have become well attuned to each other, and during the test days we had good interaction. The enthusiasm of everyone involved gives energy. It's like a construction team the way we deal with each other now. We are taking lessons learned from the Spijkenisse Bridge to the Bridge over Noord. By also embedding these in the working method, we are gaining a lot of efficiency."