Favorable MKI value due to sophisticated concrete deliveries

During the tender phase, Mebin was engaged by BAAK to help think about the concrete supplies for the Blankenburg connection. Thanks in part to the deployment of two mobile plants at the project site on deep water and three fixed (back-up) plants in the vicinity, the environmental impact (MKI value) is kept as low as possible.

Initial discussions with BAAK were held as early as 2016, recalls Bas Pije, commercial manager at Mebin. "After being awarded the contract, we delved further into the details and spent about a year and a half doing all the preparations. By the end of November 2019, we had a final agreement. In the period before that, by the way, we did supply some concrete mortar for, among other things, pouring various work floors in the project. But that is only a fraction of the quantity in our main contract: supplying 350,000 m3 concrete mortar over a five-year period culminating in 2021 and 2022."

Short supply lines

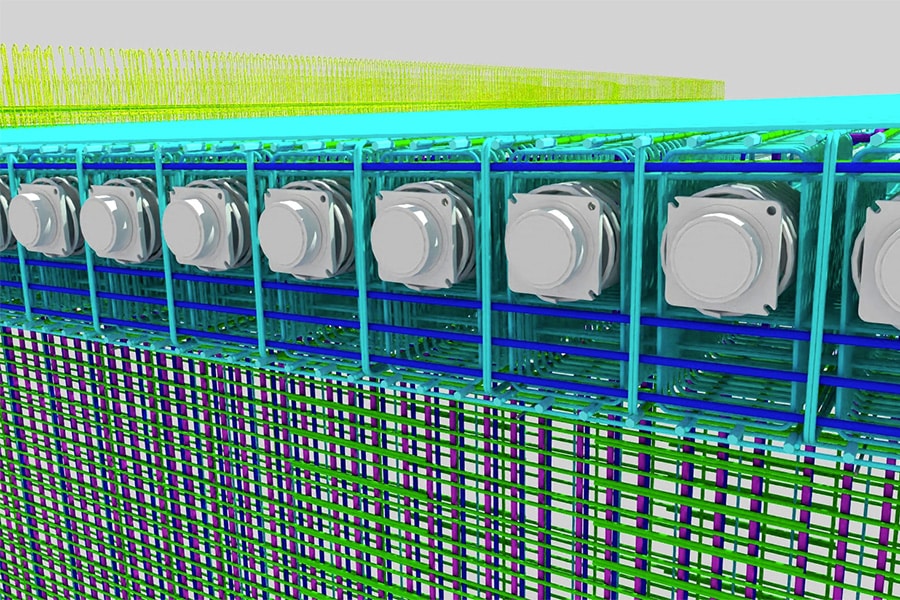

In order to minimize disturbance to the surroundings, it was decided to set up a mobile power station on the project site on both the north and south sides of the Scheur. Pije: "On the north side we selected a suitable location on the project together with BAAK, right next to the cofferdam. On the south side, a mobile power station will be set up on our own site at ENCI. We are also using our permanent plants in Maassluis and Spaanse Polder (both located on the north side) and Europoort on the south side. Indeed, the challenge lies mainly in the short time frame in which we have to deliver a large quantity of concrete mortar. Thanks to the mobile plants, transport distances are short and there will be no disruption to the surrounding area." Walter Speelman, Marketing and Product Manager at Mebin, adds: "For the supply of raw materials, there are also no traffic movements on public roads. In fact, the sites for the mobile plants are located at a deep-water quay, so we can use large ships that unload 2,000 tons of raw materials in one go."

Only at peak times are the fixed power plants partly switched on to ensure continuity or deal with possible outages, Pije explains. "A continuous dump sometimes lasts up to three days uninterrupted. That requires a lot of preparation and coordination in advance." Speelman: "We therefore have our own concrete planner stationed on site to coordinate and guarantee quality, even with varying outdoor temperatures. After all, we are dealing with many different qualities and mixture compositions from regular strength class 30/37 to high-strength concrete C75."