Beautiful work made together at replacement Langebrug Oud Ade

Main contractor Hegeman Bouw & Infra started last September - after the design phase which was completed in a construction team with the municipality and engineering firm Nebest Adviesgroep - to replace the deck of the wooden bicycle bridge.

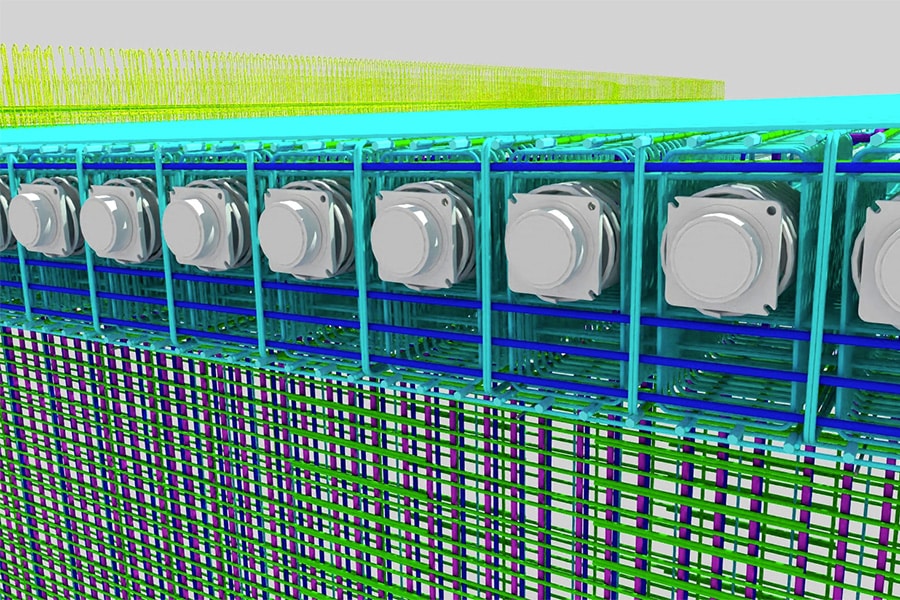

At the same time, the sheet pile walls along both approach bridges were renewed. Subsequently, the concrete car bridge will be replaced in its entirety: both the pile foundation, the piers, abutments, and the bridge deck. Kandt Aannemings- en Funderingsbedrijf was engaged for the foundation work.

Early involvement in solutions

Kandt has more than 40 years of experience in foundation work. "No challenge is something we avoid," says Bastiaan Verheul, project manager at Kandt. "In this project, the challenge is mainly in the accessibility, phasing and available working space when installing foundation piles and sheet piling. Main contractor Hegeman Bouw & Infra, after previous positive experiences with Kandt, decided to involve us in the project as early as the tender phase. Based on the experiences we have with each other, as a subcontractor we think along with the (im)possibilities of each specific project. By providing implementation support at an early stage and sometimes doing things slightly differently, you make a project feasible and doable."

Deployment of appropriate equipment

Knowledge and skill are important, so is the right equipment. Kandt has an extensive fleet of equipment and offers a suitable solution for each specific project. "When installing the 38 LeKa piles (length 18.00 - 21.00m) for the abutments and supports installed in the water, our 65-ton drilling rig was used," says Verheul. "With piles of those lengths, you normally need a large broker rig, but when -as in this project- there is no room for that, you need a compact machine with power." The KSC856, which Kandt built in-house, has enough power to drill the piles partly from a pontoon, partly from the existing abutment. "The 150m long dam wall (plank lengths between 6.00 - 17.00m) was partly pressed and partly vibrated. For pressing in a very limited space, we work with the help of a small mini-pressure rig. For the larger sheet piles, other equipment was again used." The anchoring and welding work on the purlin and cover gap were also taken up by Kandt. Verheul: "A beautiful project in which many different disciplines were applied, as many as five types of equipment were deployed and where, by thinking along with us, a feasible design was created to the satisfaction of all parties."