Concrete on roll offers innovative solution for sealing and against erosion

Concrete is almost synonymous with construction, and its applications in civil engineering are many. Precast concrete allows structures to be made in a factory hall, efficiently and under controlled conditions. But what if concrete has to follow a difficult geometric shape, for example, the one that corresponds to the soil or slopes at the site of the project, including its unevenness? Then a formwork should be placed, against which liquid concrete is poured. For solid structures this is the usual way of working, but if a thin layer of concrete is sufficient, a significant over-thickness will be poured, especially if the concrete is to be placed on a slope. This means a waste of an expensive raw material and, in addition, there is little efficiency in placing and then removing the formwork.

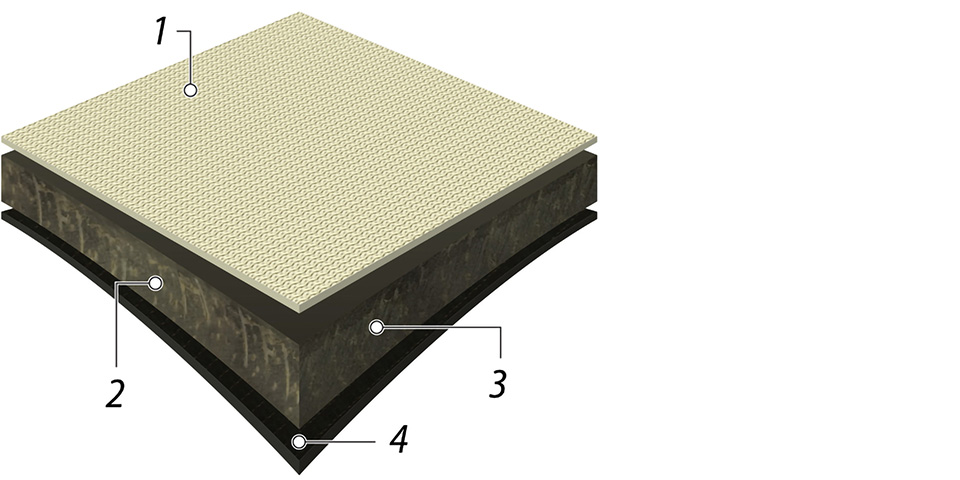

Schematic cross-section of Concrete Canvas with (1) Fibrous top layer to hydrate, (2) 3D fiber structure, (3) Dry concrete mix, (4) Waterproof backing of PVC geomembrane.

Concrete Canvas®, innovation at its best

The product consists of a waterproof backing with a layer of dry concrete mix on top, protected with a solid fibrous structure. The concrete mat comes in rolls in sizes of 1m width, and length depends on the type of mat. There are several weights per m2 possible: 7, 12 and 19 kg/m2. Mark Griffiths of Wales-based Concrete Canvas Technology is available for advice on the design of typical applications. According to his experience, a team of 3 men places approximately 200 m2/hour. Once the mat is placed, it is excessively sprayed with water. Then the curing process begins and after 24 hours 80 % of optimum strength is achieved.

The project is underway, the dikes of the tank pits are being lined with the Concrete Canvas concrete mat. Two tanks are already finished, at the system of double tanks work is in progress....

Applications:

- Sealing the drainage ditch around the canopy

- Tank pit safety lining

- Waterproofing of canals, watercourses, reservoirs, storm drains

- Protection from erosion of embankments

- Preventing erosion at overflows

- Preventing weed growth next to busy rail lines, refineries

- Repairing existing concrete infrastructure

Advantages:

- Easy to place

- The shape adapts to the existing situation, so perfectly in contact

- Dimensions adaptable to project geometry

- Continuity of construction, without open joints

- Almost all weather conditions are suitable for plaasten

- The PVC waterproof sheets are easy to weld together

- Prevents growth of shrubs and grasses, so low maintenance

- Eco-friendly because of low CO2 footprint

- Long life, uv-resistant and chemical resistant

Concrete Canvas applied as a seal for a firewater basin.

Due to the smooth surface of Concrete Canvas and its low roughness coefficient, the flow velocity at discharge is high. Therefore, there is little deposition of silt.

Steven De Maesschalck of Texion is already enthusiastic. He was present on projects where pouring concrete on slopes posed a major problem for the contractor. Concrete Canvas concrete on roll makes concrete sealing on a steep slope easy. At the top, the mat is placed horizontally in the slope, preventing undercutting. Vertical applications, for example as waterproofing against a wall, are also possible. The mat is then shot at the top.

For information and advice for projects in the Netherlands Etienne van der Kuij of ProTanks Trade (kuy@protanks.eu)