Pumping operation

In order to build the many structures of the Blankenburg connection below ground level, a temporary lowering of the groundwater level is required. Henk van Tongeren Water & Techniek managed to build a gigantic drainage installation with many hundreds of pumps, kilometers of pipes and many (emergency) power generators within a very short time frame.

"On behalf of BAAK, we are performing the drainage work for a number of construction pits for the Maas Delta Tunnel and Holland Tunnel," says Guido van Tongeren of Henk van Tongeren Water & Techniek. "In addition to national coverage with drilling and well drilling services, we have specialized in groundwater management for the larger infrastructure projects over the past decades. We are contracted by BAAK as a subcontractor and master the complete range a drainage techniques."

Wide range of extraction systems

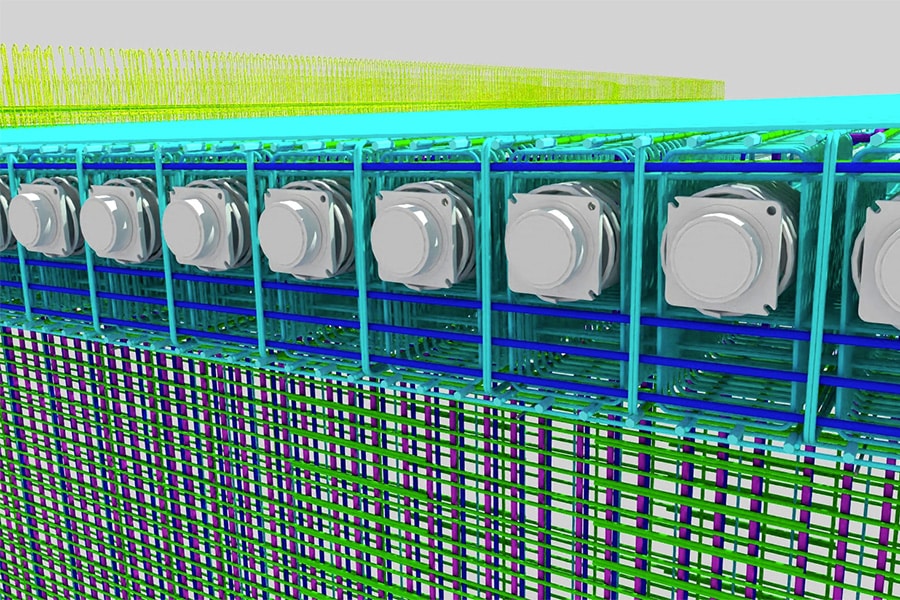

Henk van Tongeren Water & Techniek deployed a wide range of extraction installations and techniques for the construction of the Blankenburg connection, including horizontal drain dewatering, return dewatering, vertical vacuum and vertical gravity dewatering. "The biggest challenge was in the short time frame we had to commission the installations, both on the north and south sides of the Scheur," Van Tongeren acknowledges. "Apart from the many kilometers of pipelines and hundreds of pumps, at times we had more than 30 employees on the project, purely focused on pumping. In order to provide the desired service, we worked closely with our partner Tjaden (part of Hölscher Wasserbau), which also has a branch near this work site.

"Although the focus of our work is now behind us, we will certainly remain involved in this project until the end of 2022," says Van Tongeren. "For the Blankenburg connection, at least, we were able to put our technical expertise to full use. We put water to work. In character and with sustainable and innovative installation and groundwater techniques. "