A titate job consisting of 53 bridges, 74 PLCs and 3 control centers

"The Christmas Tree," was the test setup's pet name. Worldwide, never before had so many PLCs gone into a single project. Pilz did it, commissioned by the Province of South Holland, a project in which the automation of 53 bridges had to be modernized. The test setup at Pilz consisted of plates full of electronics that were stacked against each other. Project engineer Ricardo Duijser remembers that it was the management who, upon entering, just before Christmas, affectionately called the setup with all the blinking lights "The Christmas Tree. "Since then, that was the working title of our project," Duijser says.

The test setup was a dry simulation of the project. Duijser "The end result was a stable running system, which we dared to roll out with full confidence. We had done the first tests a year ago, on the Merwedekanaal. There we connected two control centers to eight bridges. That has now been working without failure for more than a year. We started the rollout of the rest, of a total of 53 bridges, in August 2018."

Each bridge can be dynamically linked to any power plant

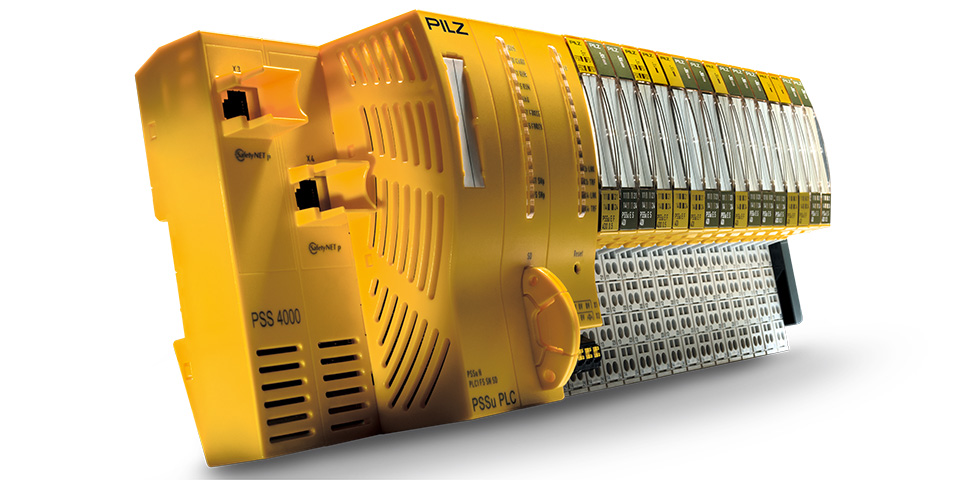

"Before, a bridge could be linked to a maximum of 2 power plants. That has now changed, each bridge can now be dynamically linked to each power station. That increases safety enormously," Duijser outlines. "In the old situation the PSS 3000 (Pilz Safety System) system was used, this has been phased out. The new PSS 4000 we applied in this rollout offers many more possibilities. By using the Ethernet protocol, there are no longer any BUS restrictions."

The scale of this project is unprecedented worldwide given the number of PLCs used.

In the context of availability, everything is interconnected. That makes it easy to convert a control center in the event of a failure. "The control center regulates the operation, per control center there are between 8 and 16 operating stations," Duijser explains. "The scale of this project is unprecedented worldwide given the number of PLCs used. It demands a lot from our organization and people. To briefly outline: A total of 23,694 lines of code were required to run the system. The project contains 554,989 local variables, 8698 of which are thrown into the proverbial ether to communicate with the outside world. As many as 319 Modbus connections are active to communicate with the control points. To get all the data to the right place, there are 540 SafetyNetp connections, our Ethernet-based safety protocol."

Using the Ethernet protocol eliminates BUS limitations.

All shoulders to the wheel

The rollout across the 53 bridges was started in August 2018. The bridges were modified, and the migration of the system took place in November. Duijser outlines, "Three power plants had to be converted one by one. Every weekend we took care of one power plant, with the corresponding bridges. Looking back, we can be satisfied with a real team effort. This titanic job shows what Pilz is like: putting our shoulders to the wheel together. We dare to go the extra mile because this kind of work binds us all together at Pilz. I'm proud of that."