Smart pole mattress design thanks to extensive automation

For the widening of the A10 motorway at the De Nieuwe Meer junction, the TriAX construction consortium faced a complex challenge: building on a postage stamp, with little space and even less time. Traditional solutions, such as preloading with sand, were simply not possible. That is why it was decided to base the expansion of the A10 South on a pile mattress. CRUX Engineering was called in for the design, which, thanks to extensive automation developed with the help of sister company CEMS, was able to offer an optimized design.

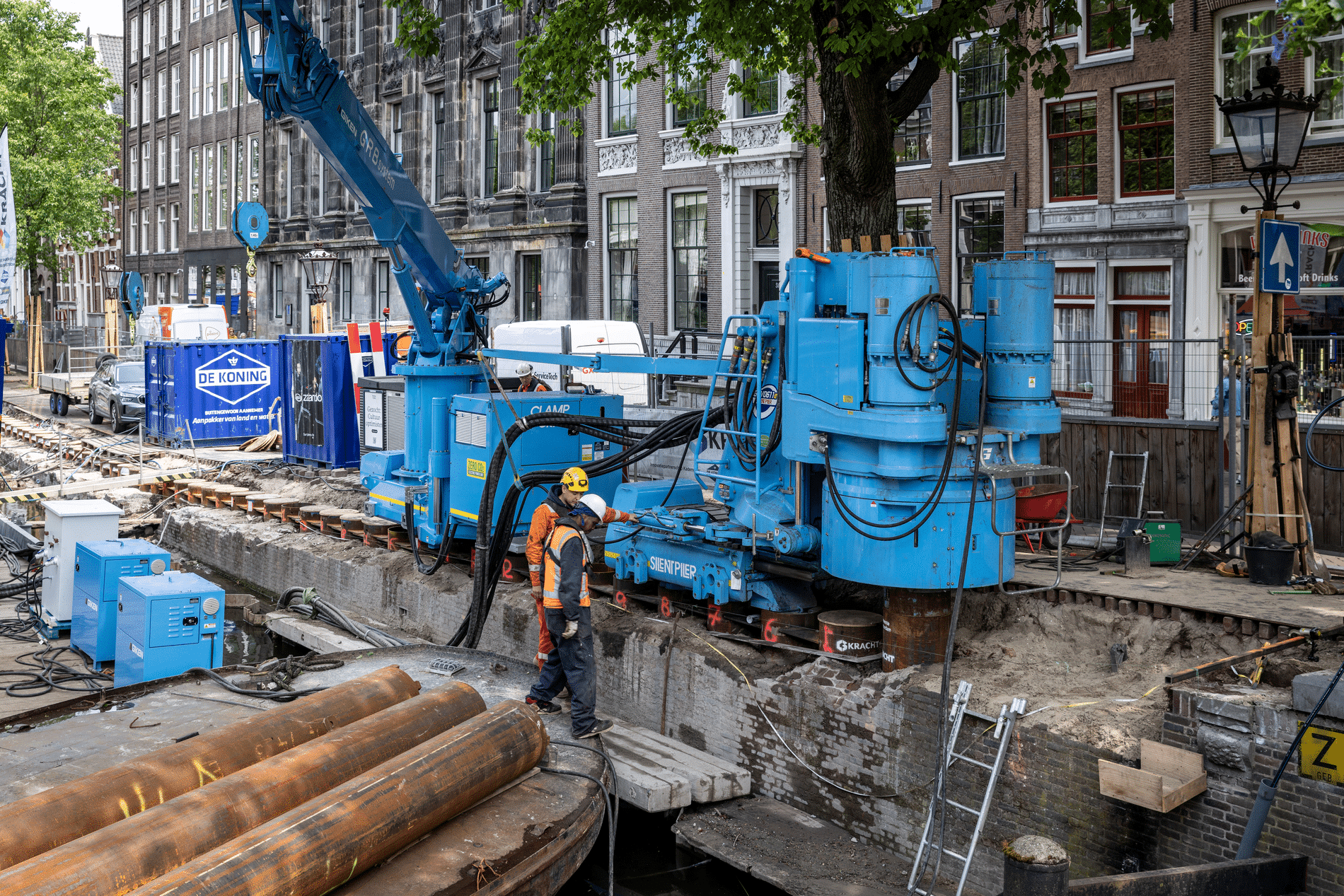

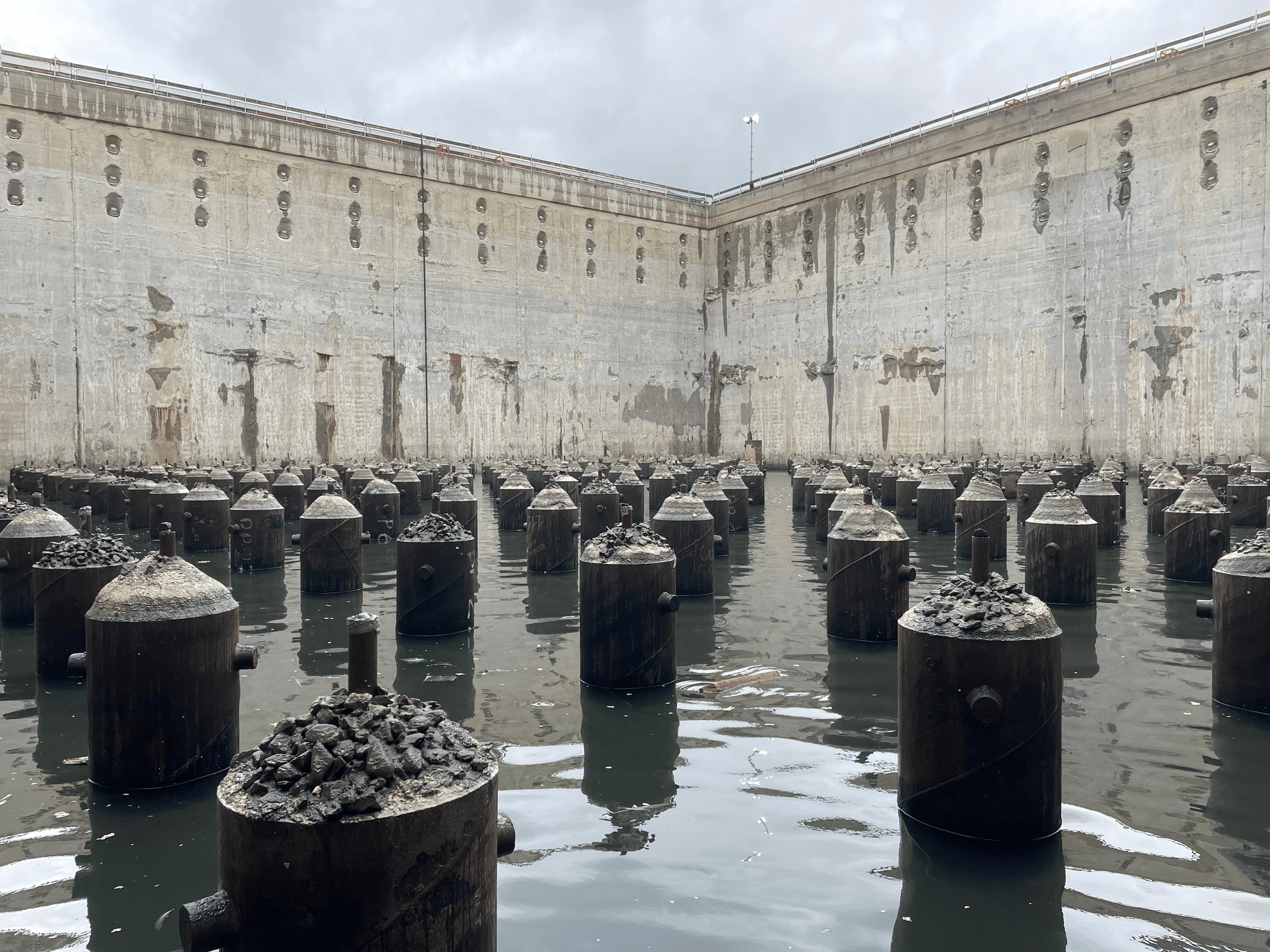

The pile mattress consists of foundation piles with a diameter of 300 to 450 millimeters, topped with concrete covers measuring 1 meter square, explains Johan Zwaan, geotechnical specialist at CRUX. “On top of that comes a geogrid and a layer of granulate, which together form a stable floor on which the road can be further constructed.” Designing such a structure is anything but simple. “Historical modifications to the A10 South, construction phases, interfaces between different disciplines, loads during construction and use, pile lengths, stability of the existing A10 South, and the impact on the surrounding area must all be taken into account. For example, the former ING building De Schoen is only 1.5 meters away from the work area.”

Complex calculations

CRUX used finite element calculations in Plaxis to model the entire subsoil, including the pile mattress and construction phasing. “This requires complex analyses in which all parameters are considered for each phase and even information about the construction of the original A10 South is taken into account. These are complex calculations that usually take a lot of time and are characterized by a lot of repetition,” says Zwaan. “Normally, calculations are made per 100 meters of road length, but thanks to extensive automation, many more calculations could be performed in less time, with an average of one calculation per 35 meters. This resulted in a customized solution for the specific design solutions and required pile foundation per cross-section.”

Optimizing instead of modeling

“We used Python scripts to link Plaxis to the project data, which meant that models were largely constructed automatically,” explains Pablo Vásconez, geotechnical specialist and software developer at CEMS. “Geometry, soil parameters, construction phasing, and water levels were thus imported consistently and error-free. Whereas engineers normally spend a lot of time on repetitive modeling, the focus was now on the quality of the results and optimizations in the design.”

Lighter and more effective design

This approach had several advantages. First, it enabled faster and more reliable work, because the basis of each model was correct and uniform. “In addition, automation made it possible to calculate many more scenarios and locations than usual, resulting in a lighter and more effective design. The risk of human error was also significantly reduced,” says Zwaan. “And through PileCore, also a CEMS product, the pile length of the foundation was further optimized. In total, around 3,500 piles were considered over a length of 1.3 kilometers of pile mattress.”

If you want to use smart automated tools, it is important to start with automation at an early stage because it often involves a customized solution and therefore requires development time that only pays off later in the project, advises Vásconez. Zwaan adds: “Whereas many projects only try this at a late stage of the design process, and therefore often fail, TriAX has shown courage by choosing this approach from the outset. The result is a more efficient and robust design within the tight constraints of available space and design time for the project.”