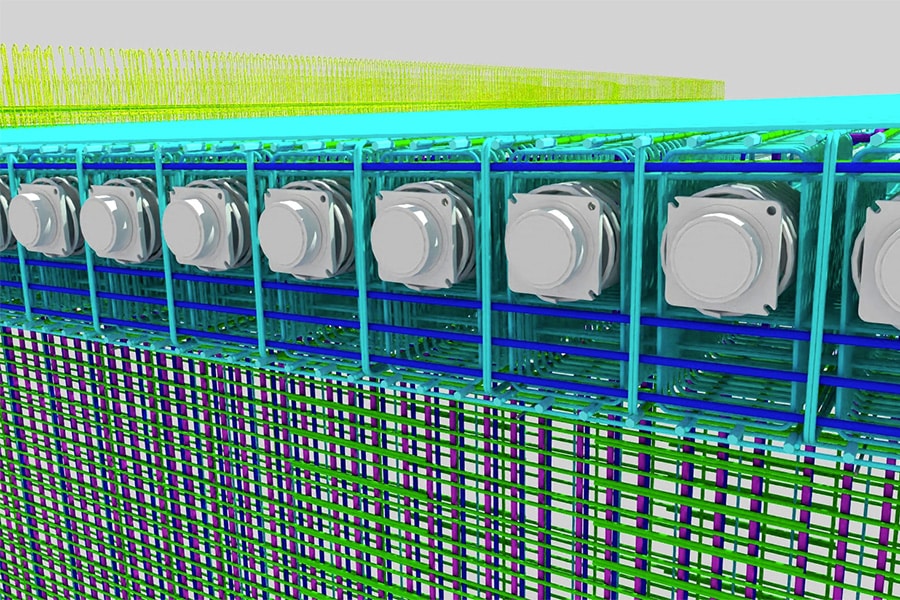

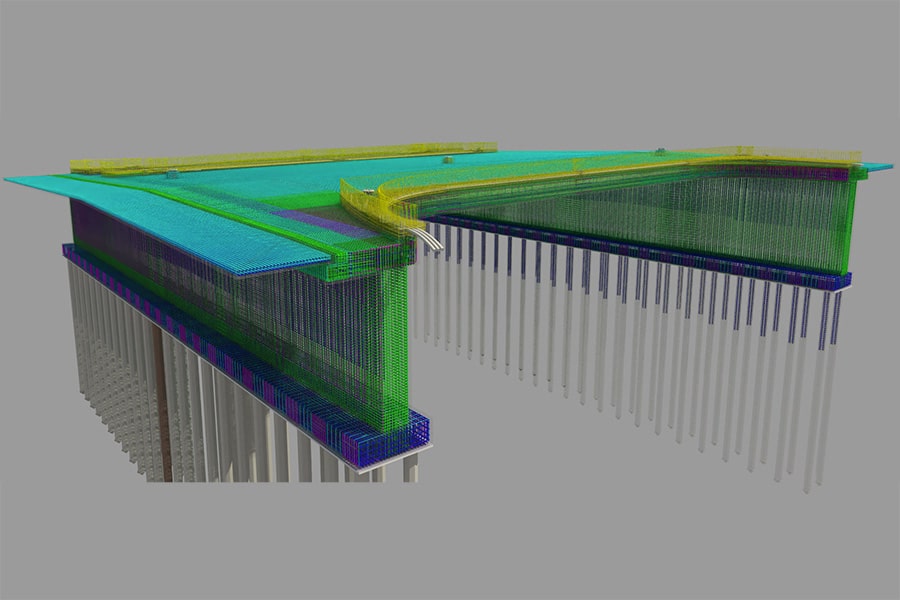

3D reinforcement model for Princess Alexia Viaduct

Following the Princess Amalia Viaduct a few years ago, Spanberg is now also working out the reinforcement for the future Princess Alexia Viaduct on Maasvlakte 2. The 3D reinforcement model also forms the input for Spanberg's bending machines, which also take care of applying the reinforcement.

The Princess Alexia Viaduct replaces the level crossing on Maasvlakteweg that now opens up the area around Princess Alexiahaven and the level crossing with the railroad, a utility strip and the Container Exchange Route. The new viaduct should ensure the safe and smooth flow of traffic to and from the Alexiahaven. "On the basis of a good and long-standing cooperation with main contractor BAM, and partly given our experience with the Amalia Viaduct, we have been awarded the work," says Dennis Knaap of Spanberg. Spanberg will be responsible for realizing the execution design and drawing out the reinforcement in 3D and 2D."

Eurocode

The Princess Amalia Viaduct has two decks, which are also present with the same dimensions in the new Princess Alexia Viaduct, Knaap continued. "Nevertheless, there is a substantial difference, as the newest viaduct has one more deck present, i.e. two axles. In the case of the Princess Alexia Viaduct, moreover, we chose to build part of the deck with prefabricated beams, because of the railroad line we cross." There is hardly any synergy with the earlier viaduct, according to Knaap, and that has to do with the changed principles in the Eurocode. "Over the years, the reinforcement has often become more finely meshed and staggered welds are often required. This makes the prefabrication of the reinforcement, among other things, by applying welding, but also by spider mats (roll mat) more difficult or if not impossible."

Lots of preload

The 3D rebar model is automatically read into Spanberg's bending machine. "Because the machine itself controls production, human error is minimized. Creating a 3D model does take time and energy, but the turnaround time of the whole thing is faster and failure costs in execution are reduced," Knaap emphasizes. "And that's just as well, because the lead time is relatively limited. Another challenge is the large amount of prestressing in the decks. When those cables are tensioned, enormous forces rest on the end of the deck, requiring more reinforcement locally. These are also the crucial places to model 100% clash-free." Design and construction of the Princess Alexia Viaduct began in the third quarter of 2024, with completion scheduled for the end of 2026.