Efficient excavation process Juliana Canal thanks to Trimble machine control

Virtually all of the machines used to excavate and install the rock in the Juliana Canal are equipped with Trimble Earthworks machine control. Thanks to the great accuracy of this system, machine operators see exactly what they (should) be doing. Niels Timmermans, product specialist at SITECH explains how Trimble machine control contributes to an efficient excavation process of the canal.

Most companies know SITECH as the Trimble dealer for machine control. They supply GPS systems, measurement sets and all the software and associated cloud solutions. So too for the widening of the Juliana Canal. For this, the machines are equipped with Trimble machine control, from excavator to bulldozer. Niels: "Trimble machine control systems help contractors complete work faster with less reworking, setting out and dimensional control. In the case of the Juliana Canal widening project, we are doing this in collaboration with PS Survey, a client of ours and responsible for sizing the project. They made the designs for the machine control. However, the question was How are you going to set this all up? We wrote a plan for this. This is also how our services and products come into their own even better: thinking about the machine controls in advance, so that you can set up the process optimally."

Three base stations

Some 60 GPS machines are at work in the widening of the Juliana Canal. Of these, 55 are equipped with Trimble machine control. According to Niels, there are few projects right now where so many machines are working at the same time. "When it comes to machine control, you set a number of priorities to make the project run as efficiently as possible. For elevating the Juliana Canal, accuracy in particular was very important. With that in mind, we decided to work with three base stations. The work on the Juliana Canal is also divided into three work sections, so each work section has its own base station. The advantage of this is that data continuity is always guaranteed. Suppose one base station should fail, we can always fall back to another base station."

Always up-to-date work information

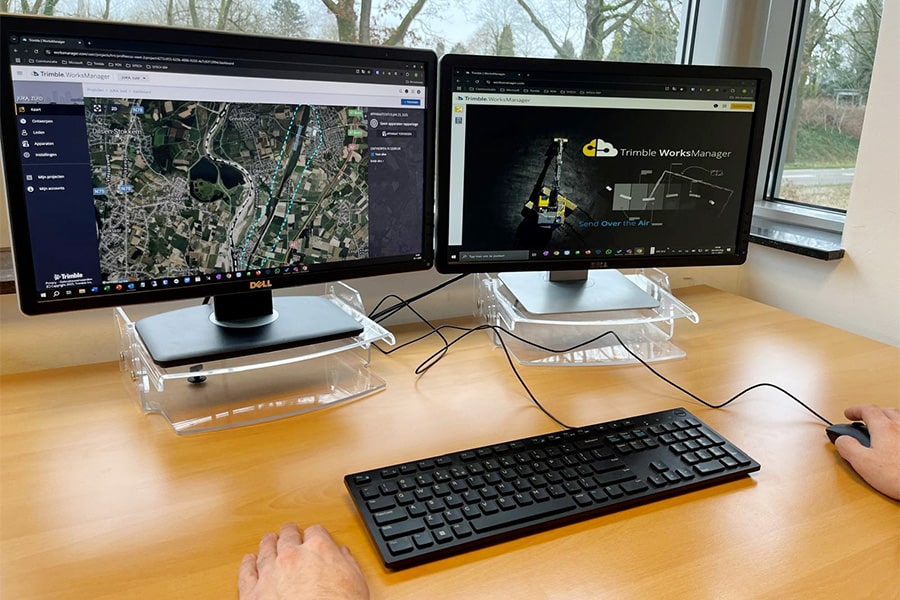

A second important requirement was data transfer to and from the machines. Trimble works with the cloud environment Worksmanager. This gives you the ability, as a general contractor, to enter into so-called partnerships with your subcontractors who supply the machines. "So all the machines were already linked together in the cloud via Worksmanager even before they were deployed on the project. So on day one, the machine operators could get straight to work because they had the most up-to-date 3D excavation model. Whereas our help desk normally gets a lot of calls on a first working day, because drivers have to get used to the system, now it remained very quiet. So no downtime or delays, which saves a lot of time and costs. An additional advantage of the Trimble Worksmanager is that a design is also immediately updated in the event of a possible change. The operator receives immediate notification of this. So the risk of errors from working with an outdated design is also very minimal."

"For us, the Juliana Canal is an exemplary project, because we have been able to think along beforehand. Machinists can start work right away every morning without nagging and downtime, which makes for more efficient, better and, above all, more enjoyable work."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met SITECH Netherlands BV.

Contact opnemen

Contact opnemen