Replacement of historic railroad bridges at Amsterdam East Access

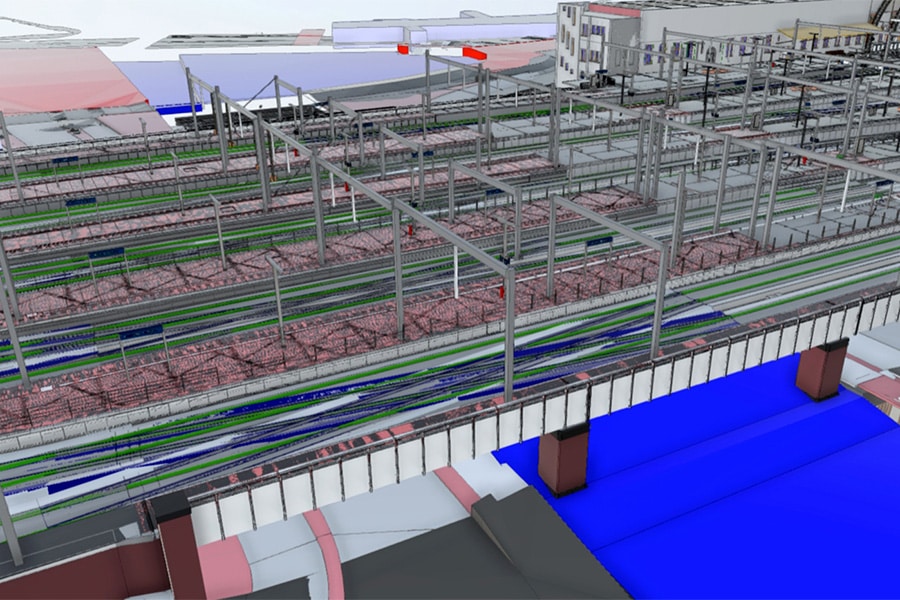

ProRail's ambition is to renew and improve the Netherlands' aging rail infrastructure. In line with this vision, four steel and one concrete railroad bridges will be replaced on the east side of Amsterdam Central Station over the next five years. These five bridges, four of which are more than a hundred years old, are an important part of the rail network that connects Amsterdam to the rest of the Netherlands. Rebuilding the station and adapting the infrastructure are necessary to accommodate more trains and passenger growth by 2030.

Starting in 2024, one rail bridge will be replaced every year. A necessary step due to the aging of the current bridges and the need to expand the platforms. Iv is working with Dura Vermeer, Hollandia, Takke Breukelen, Sterk, CRUX and Mammoet on the Oostertoegang Amsterdam project. Commissioned by Dura Vermeer, Iv is responsible for the integral design of the five railroad bridges.

The design

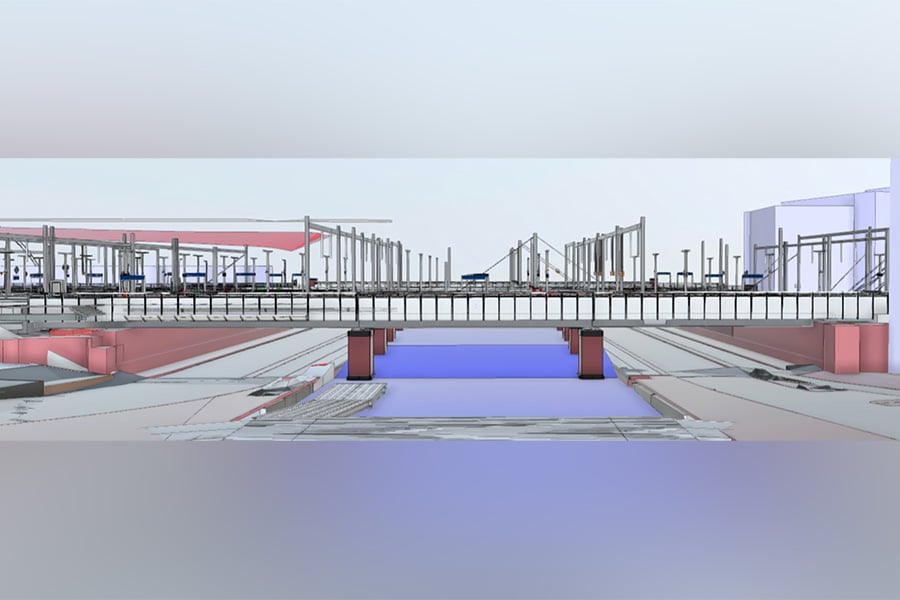

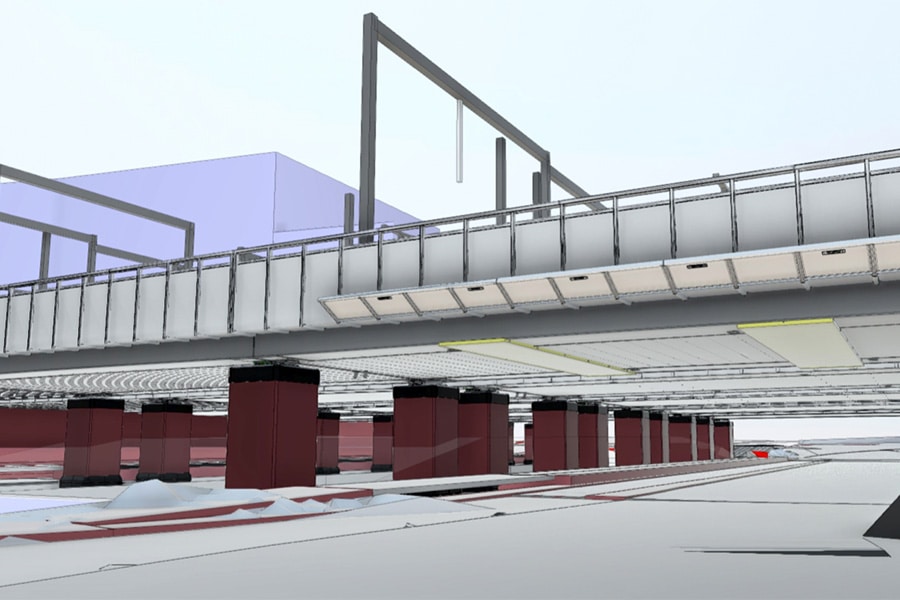

Four of the five bridges will have completely new piers, abutments and foundations. For the fifth bridge, the existing abutment will be retained, which presents a specific challenge in this project. Each bridge consists of three spans on concrete piers and abutments. Iv developed the tender design of the steel bridges and supporting structures into the final design. Following the final design, Iv was involved in the fabrication and installation of the steel bridges.

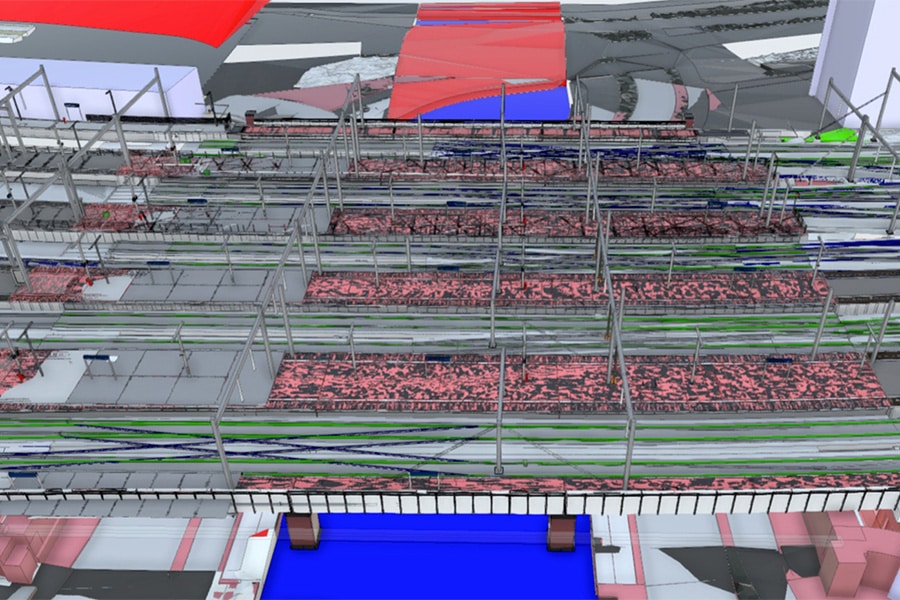

Although the bridge sections are similar, they are not 100% identical. This requires an accurate and efficient design process. By (partially) automating the computational analyses and optimizing the modeling and drawing work, the design of these bridges could be completed with minimal effort, without increasing costs. It also allowed the contractor's requirements and preferences to be easily tested for feasibility. Mathematically, Iv demonstrated that the bridges can be supported by the foundation and that the steel bridges meet all requirements.

In rail projects, there are hard physical constraints to ensure safe rail passage. For example, a fixed height of the rail tracks is necessary. This follows from the connecting track bodies and structures. The ensuing height of the platforms is also essential, to facilitate safe boarding and alighting of train passengers. There are also constraints from underpass elements such as streetcar tracks and roads. All these aspects have been included in the design to enable functional use.

Special challenges

The replacement project of the historic railroad bridges presents several unique challenges. The substructure plays a crucial role, particularly through the use of existing stamped concrete. This old concrete presents uncertainties in cohesion and stiffness. The uncertainties were addressed in the design by considering the upper and lower limits of the properties (strength and stiffness) of the stamped concrete. To ensure the safety of the structure, a longitudinal force analysis was performed. This analysis also served as a design tool to optimize the supports. This approach reduced the number of piles required, both saving costs and improving the sustainability of the project.

Another particular challenge in this replacement task involves Bridge 5, which uses the existing abutments and foundations. These were originally designed to early 1990s standards, which differ from today's Eurocodes. To ensure that these existing sections can carry the new loads, Iv first conducted an archival study with old drawings and calculations. These were then modeled to assess whether the existing substructure is strong enough to safely support the renovated bridge.

Permitted drilling zones

Drilling through the old concrete structure presented significant safety risks and challenges. Strict adherence to the contractual requirements on the allowable drilling zones in the existing structure therefore posed a challenge. Together with the client, we looked at the possibilities within the specified requirements to arrive at an optimal and safe design that met the requirements.

Strict planning

The availability of train sections is often determined two years in advance. This means that the timing of major work, such as the installation of a bridge, is determined far in advance and the schedule must be strictly followed. This became a challenge when the original steel contractor went bankrupt. A replacement then suddenly had to be found and the design changed. These challenges require creativity and innovation, as well as intensive cooperation and coordination between all disciplines. To give hands and feet to this, there was a joint working day every Wednesday in Amsterdam. A dynamic day where executing parties, the design manager and colleagues from Iv and Dura Vermeer came together and together sought the best solutions for this project.