Electric cable pulling based on pure hydropower

The company specializes in laying cables and pipes, installation of electrical and fiber optic cables and directional drilling. Van de Beek Kabels en Leidingen from Neerijnen has been realizing projects where cables and pipes have to be laid or pulled since 1977. The family business values quality and innovates constantly. "All in the interest of our clients, who like to see their projects run smoothly and be completed on time," explains Arie van de Beek. Van de Beek has been successfully doing business with HMS Machines of Gouda for more than 25 years. The latest 'feat' of HMS Machines bears the name 'WATUCAB'. It is no coincidence that we are the first to find this machine, which propels electric cable through pipes using water power, at Van de Beek. "We are always looking for innovative solutions and like to work with the very latest resources. With us, WATUCAB complements the traditional way of pulling cables and blowing fiberglass in a beautiful way."

Not pulling but pushing

"The big advantage of the WATUCAB is that the cable is pushed through the tube, so to speak, propelled by water power. That puts hardly any strain on the cable itself, unlike pulling on the cable with a winch," Arie explains. "With WATUCAB, we also reduce environmental pollution. A good example: you normally do a cable route of 2 kilometers in phases, depending on the length of cable you are processing. For that, the length that's on the reel does have to be dug open and drilled at once, when you're working with a winch in a trench.

With WATUCAB, the cable is laid entirely in casing. On the section of the route between any drillings, casing is now also installed. If necessary, the trench required for this can be closed daily. This provides a huge reduction in environmental nuisance."

Another big advantage is that the cable hardly experiences any friction from the tube, because there is a film of water between the cable and the tube wall. "So there is much less pulling on the cable and the cable experiences virtually no friction. So the forces on the cable are significantly less than with the traditional method. This keeps the cable optimally protected and you avoid potential damage to the cable that needs to be repaired or perhaps replaced. You understand that this makes the power company very happy. A repair in the form of splices is costly and every splice is a potential weak link in the power grid."

How long do you want the cable to be?

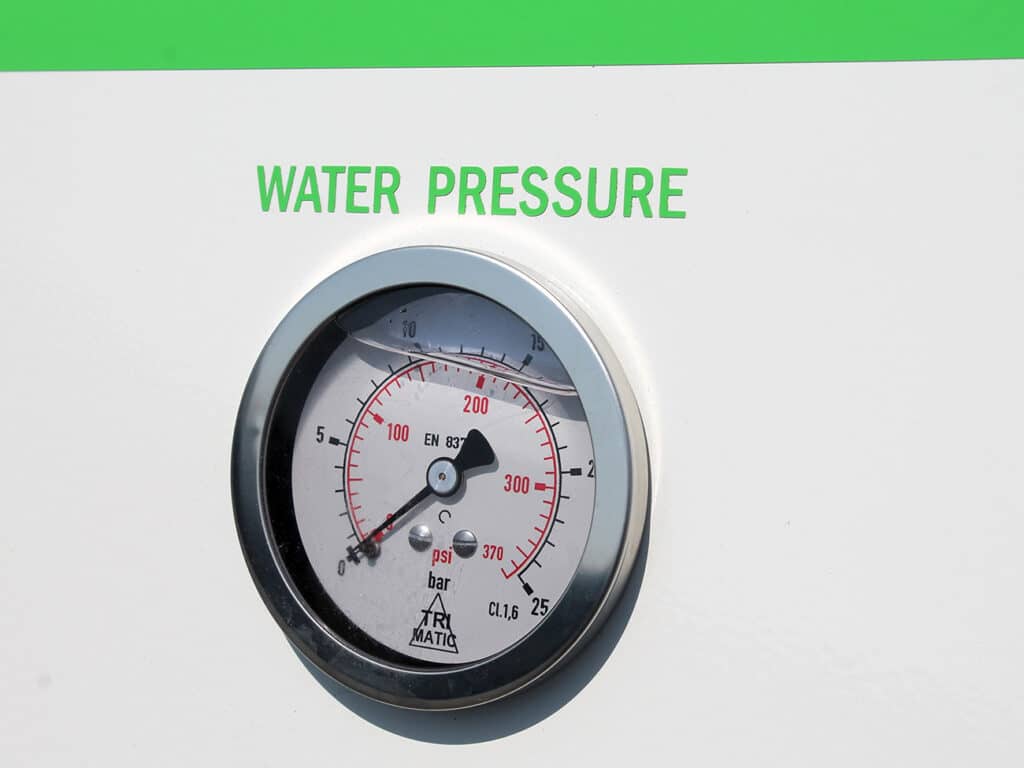

WATUCAB makes it possible to fit longer cables than has traditionally been the case. Arie: "The total length of cable that fits on the reel has now become the limiting factor. This is because the water pump delivers a continuous pressure, which is related to what the pipe can take. You can keep feeding cable, up to lengths of about 2 kilometers." Another added benefit is that with the use of WATUCAB, fewer operators are needed. "In these days of 'hands shortages,' that's a very welcome bonus," Arie outlines. "If you add up all the factors, it's pure profit at the bottom line. Longer cables in one go, fewer splices, less chance of cable damage and then also having access to valuable data generated by the WATUCAB's computer. Our expectations of this new machine are high."

Cross-border testing

Van de Beek conducts tests on its own initiative on the equipment used there. "We built a test route with several bores, running a medium-voltage cable through a jacket pipe. There are extreme bends in the route, which you will almost never encounter in practice. There is a transparent piece of pipe in this route, which provides a view of the propulsion process. Our engineering department collaborated with Willem Griffioen of Plumett, the parent company of HMS Machines. Together the test track was designed and the tests were done. We already have a job in store for the WATUCAB and our client is coming to see for himself how well this method works."

Total Cost of Ownership decreases

"We have been working as in good partnership with Van de Beek Kabels en Leidingen for more than 25 years," says Friso Talsma of HMS Machines. "We are more or less 'court supplier' in Neerijnen and work intensively together to take the market for installing cables and pipes to a higher level. On the one hand to provide maximum relief to clients, and on the other hand to respond to the increasingly stringent requirements imposed on the work. Less disruption is one such requirement that will only get tougher. Less damage to the cables is good for the economic interest and providing continuity for BV Nederland."

When asked whether working with WATUCAB drives up the cost price, Friso replies, "On the contrary. If you look at the bottom line, you will see that because of all the advantages this new system offers, the TCO (Total Cost of Ownership) goes down. You cannot compare this method with the traditional pulling of cables. Besides the totally different methodology, WATUCAB also leads the way when it comes to generating valuable data. The machine logs a lot of data and you can see in "real time" how the cable is doing. The reason for being the first to introduce WATUCAB to Van de Beek is not only because of our good relationship, but certainly also the testing capacity in Neerijnen." Arie adds: "We have the technology in-house to measure tubes to the nearest centimeter. For this we use a gyro that we pull through the route and accurately log the position centimeter by centimeter. We then feed the route data into the WATUCAB computer, which uses it to calculate how much water is needed." Friso: "The WATUCAB data dump is 100% compatible with the Jet Planner software. The outcome is no longer an estimate, but accurate 'as built' data." Added Arie, "This is so far the most intelligent and controlled way of installing cables we have ever seen. We also reduce the tuning moments with this, because you install the cable in one go."

WATUCAB contributes to the customer promise

In conclusion, Arie says, "Van de Beek Kabels en Leidingen is not at all about increasing our market share. What we do care about is keeping our promises to customers. We are not volume driven, but quality driven. This allows us to anchor our existing position in the market even more firmly. WATUCAB helps us do that."