ACDE Netherlands now sells quality reconditioned machines

Circular and economic a win-win situation

The Netherlands wants to have a circular economy by 2050 in which waste does not exist, renewable raw materials are primarily used and products are reused as much as possible. In conversation with Joost Wassink of ACDE Netherlands, we quickly find out that his company is already responding to this. Not only new and young used machines are for sale in Duiven, but from now on also qualitatively reconditioned machines.

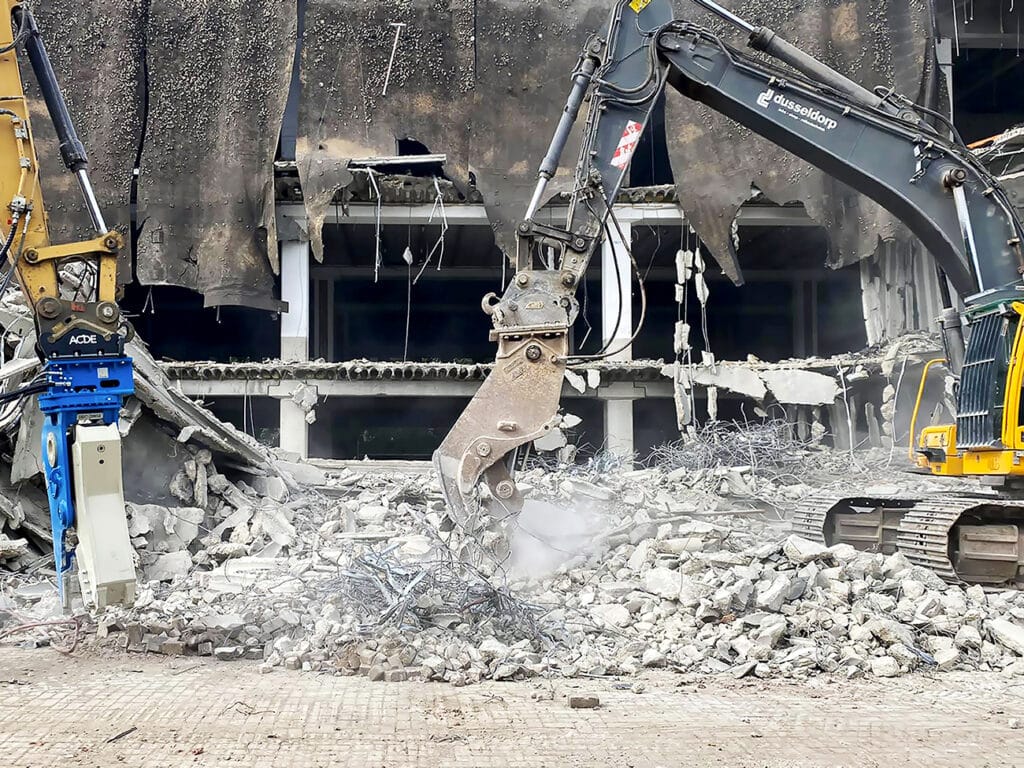

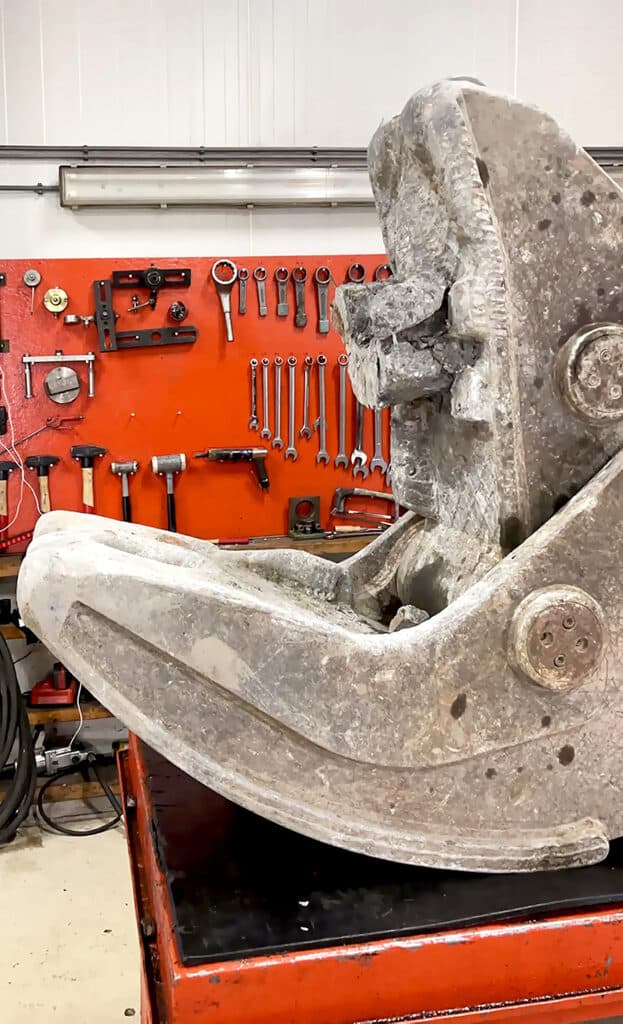

ACDE has been a household name in the demolition and recycling world for more than a quarter of a century. Not surprisingly, with those years of experience, the step towards a more circular economy is being taken. This step is partly due to the increasing number of customers who are themselves involved in circularity. Take BMG from Wageningen, for example, which presents itself as the total partner for demolition work, asbestos remediation and infrastructure and groundwork. BMG not only buys new machines from ACDE Netherlands, but has now also purchased a reconditioned sorting grab, demolition hammer and two pulverizers. Understandable from a company that is primarily concerned with "circular, customized and careful demolition.

Rental companies also see the value of reconditioned machines. Take Bunnik Verhuur from Zegveld, for example, which has included two reconditioned demolition hammers and a reconditioned Okada pulverizer in its rental program. And that to everyone's satisfaction, because the overhauling is done in-house by ACDE Netherlands, so by professionals who know what is expected of a demolition and recycling machine. In that respect, these are used machines that are as good as new after overhaul. That is why there is a one-year warranty on them, where normally it is six months for used machines.

Also economically smart

Is buying reconditioned machinery an act of environmental consciousness? Yes indeed. But there are other reasons to take that circular step. Joost Wassink: "We are not doing it out of luxury. We are currently plagued by delivery problems. We see the delivery times of new machines rising sharply, causing stocks at suppliers to melt away and manufacturers to no longer be able to meet demand.

In addition, we see all around us that everything is becoming more expensive thanks to rising inflation and the war in Ukraine. So price is also a topic of discussion more than before. With reconditioned machines, we can keep the price relatively low while the delivered product continues to meet the desired high standards. Just say a circular and economic win-win situation."

View of machines

Finally, Joost Wassink has some fun news to report: "We have developed our own tracker and tested it in practice over the past three years and with results: the first customers are ordering trackers for machines not supplied by ACDE with some regularity. Also, some stolen machines have already been recovered and retrieved with it. So now it is time to go broadly into the market with this FG tracker."

The FG tracker is very compact and therefore easy to hide. It can even be potted, making removal almost impossible. The battery lasts at least 4 years. In particular, the tracker can also be used to monitor the condition of machines. It records the exact number of hours worked and how a machine - for example, a demolition hammer - was used. This also makes it possible to intervene in time if something is threatening to go wrong.