Volvo Trucks' I-Shift: still a groundbreaking innovation after 20 years

By the end of 2020, more than one million Volvo Trucks worldwide were already sold with I-Shift. And even twenty years after its introduction, development is not standing still.

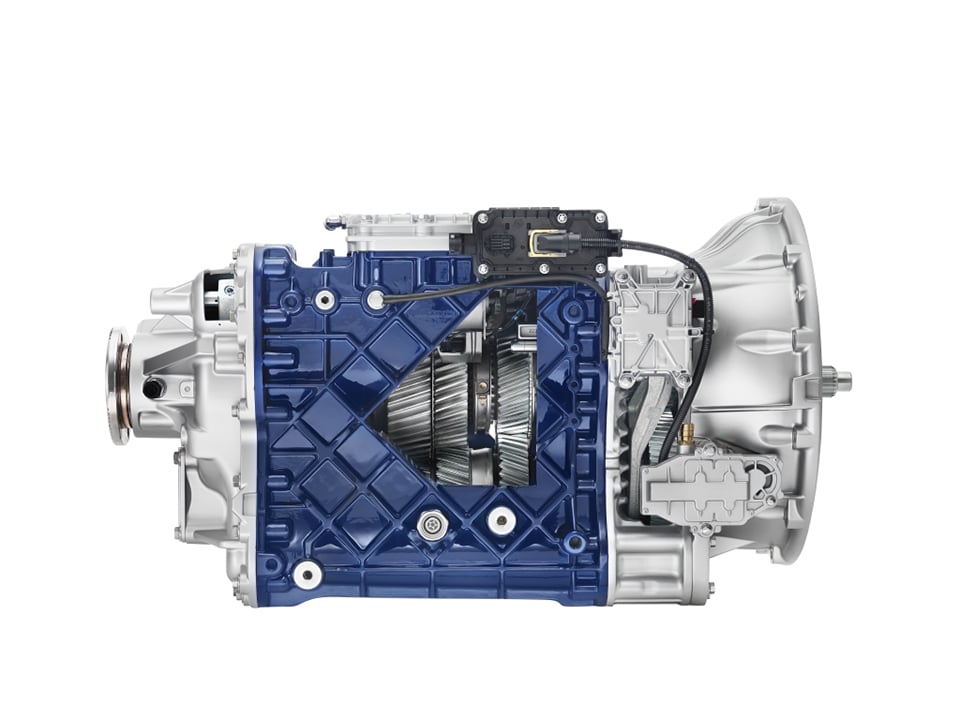

When I-Shift was first launched in 2001, Volvo Trucks confirmed its strong belief in a clutch-based transmission system as the most efficient design for automatic shifting. Since then, more than one million trucks worldwide have been sold with I-Shift technology. Today, all Volvo FH, FH16, FM and FMX trucks are equipped with I-Shift as standard. Because it is an automated system, I-Shift contributes to lower fuel consumption - and thus a reduced impact on the environment - and also improves safety and driveability benefits in terms of reduced noise, vibration and physical strain on the driver.

"I-Shift was and still is a big game changer. Today we sell I-shift all over the world. In North America, we have gone from single-digit numbers in 2007 to more than 90% of all Volvo Trucks there now being equipped with I-shift. This impressive development clearly reflects both increased efficiency and driver appeal, " says Pär Bergstrand, manager Heavy Duty Transmission at Volvo Trucks.

I-Shift, developed by Volvo, is fully synchronized with the rest of the truck, as the transmission uses the information available from both the engine and the vehicle to work together in the most optimal way for different applications and truck combinations.

"This synchronization distinguishes I-Shift and makes it equally versatile. I-Shift is the positive result of years of hard work by our skilled engineers, valuable field tests with customers and technological advances throughout the Volvo Group ", explains Pär Bergstrand.

The success of I-Shift lies in its ability to form a unit with the entire powertrain., Through continuous improvements over the years, I-Shift meets the requirements of a wide range of transportation applications, not only for high performance and efficiency, but also for optimum driveability and comfort.

Over the years, Volvo Trucks has pioneered numerous new intelligent features that both drivers and carriers have come to appreciate. Here are some examples.

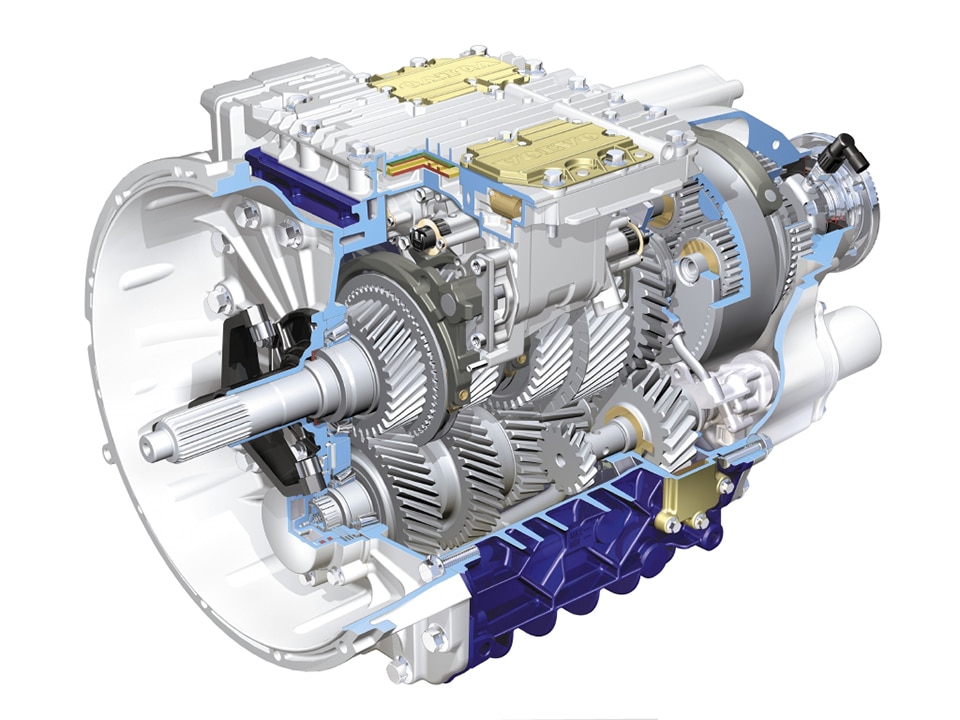

I-Shift with Dual Clutch

In 2014, Volvo Trucks introduced the I-Shift with Dual Clutch: a heavy-duty dual clutch for smooth acceleration and seamless shifting. Inspired by the gearboxes used in racing cars, the I-Shift Dual Clutch shifts with no loss of power. Torque remains optimal and the truck does not lose speed while shifting gears.

I-Shift with creep gears

In 2016, Volvo Trucks brought I-Shift with creep gears on the market. It allows effortless driving off with a heavy load from a standstill or in hilly or poor terrain. I-Shift with crawl gears allows a truck with a train weight of up to 325 tons to start from a standstill on a flat road. The gear ratio allows the truck to crawl at speeds as low as 0.5 km per hour, which is useful when performing precision maneuvers, such as on construction sites, building roads or transporting timber.

I-See uses cloud-based map data

I-See is a separate system that can be added to I-Shift, designed to analyze the topography of the route and use that knowledge to keep the truck in the most fuel-efficient gear. I-See, updated in 2017, assists the truck in maintaining a consistent average speed by analyzing cloud-based map data about the topography of the road ahead and telling I-Shift when it is the most appropriate time to change gears to save energy, and thus fuel.

I-Shift with Change Direction function

The 2020 launch of Volvo Trucks' new heavy-duty series brought with it the introduction of another innovative feature: I-Shift with Change Direction function. This new feature allows the truck to change direction without the driver having to use the brake pedal, a feature that is particularly useful for construction, forestry and mining operations where it is more productive to perform repetitive maneuvers back and forth at lower speeds.

The latest generation of Volvo Trucks also further reduces fuel consumption. For example, the new Volvo FH with I-Save technology, Volvo Trucks' most fuel-efficient long-haul truck to date, can reduce fuel consumption by up to 10 percent*

But development certainly does not stop here. "I-Shift will be further enhanced in the near future both for diesel trucks and alternative fuel trucks. I-Shift will also be an important part of our electromobility journey. As an advanced automation technology, I-Shift offers unique opportunities to contribute to Volvo's fully autonomous transport solutions of the future ", concludes Pär Bergstrand.

*The difference in fuel consumption is calculated by comparing the cost of diesel and AdBlue for I-Save: the new generation Volvo FH with D13TC Euro 6 step D including the long-haul fuel package, with the classic Volvo FH with D13 eSCR Euro 6 step D without the fuel package

for long distances. Actual fuel economy depends on many factors, including driver experience level, use of cruise control, vehicle specifications, vehicle load, current topography and weather conditions.