Exhibition premiere: VTN now back on the Benelux market

SAES International, exclusive distributor of Epiroc and Erkat, among others, will take over distribution of the VTN program, consisting of attachments for demolition, recycling, transfer, offshore and earthmoving, starting January 2020.

Well known to many: Henk Saes, entrepreneur pur sang. When he was a student, some 40 years ago, Henk was a real enthusiast and went to every fair in the world. Nowadays he and his own company exhibit at trade fairs in the Benelux and beyond. At the Infrarelatiedagen in Hardenberg, the director and owner of SAES International BV from Weert has a first appearance.

Henk Saes: "It's great that we can add the VTN products to our Epiroc and Xcentric Ripper range."

SAES International distinguishes itself with its great brands and equally great equipment for demolition, recycling, transfer, offshore and earth moving. As an exclusive distributor, Henk can add VTN as a brand from January 2020! At the fair itself, Henk explains how this came about. "VTN was looking for a good partner to return to the market within the Benelux. SAES, as with Epiroc, offers the right know-how, support and service that VTN wants to offer its customers. Moreover, we are very active in the Benelux and rent total solutions to customers, also worldwide." Reasons enough for VTN to partner with SAES.

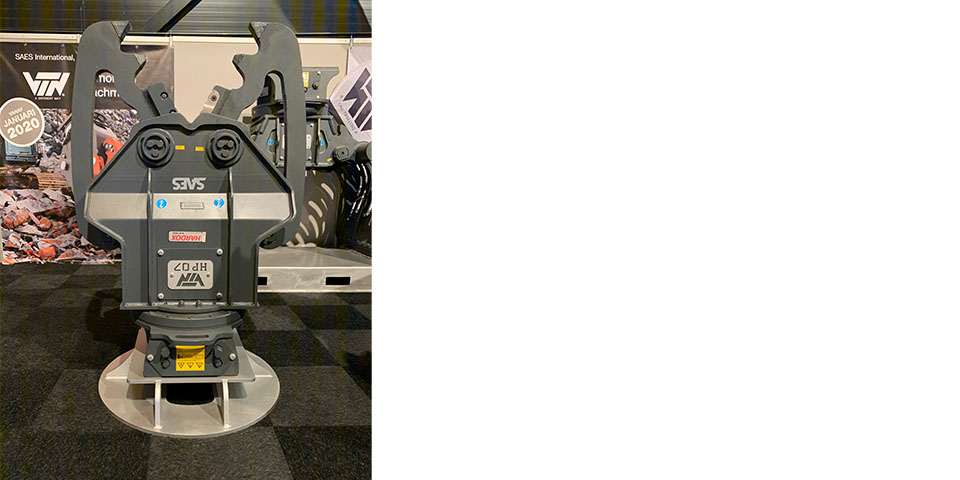

VTN HP07: the hydraulic demolition shears with booster technology.

With head and shoulders

"It is fantastic that we can add VTN's products to our Epiroc, Erkat and Xcentric Ripper range," Henk continues. "Because SAES stands for quality and the Italian brand VTN stands head and shoulders above the rest worldwide. The company continues to develop so that the products get better and better. So with the widest program and the most experience, VTN is a perfect complement." In addition to Epiroc's SDT line, SAES offers VTN's entire demolition line; from concrete shears, pulverizers, iron shears, demolition, poly and sorting grapples to combination shears.

SAES adds VTN to its product range as the exclusive dealer in the Benelux region.

Demolition shears with BOOSTER technology

In the booth behind Henk shows off the VTN HP07: the hydraulic demolition shears with booster technology from VTN's HP series. There are no fewer than 7 models within the HP series for excavators with a working weight of 1.5 to 30 tons. Henk: "VTN responds extremely well to the demand from the market to be able to work quickly in an efficient and effective manner. So too with this HP07. It is a compactly designed machine with 360° rotation, making it the ideal solution for primary demolition. The patented "BOOSTER Power Multiplier" technology, a pressure booster acting on the cylinder, makes the HP07 the perfect tool on the construction site. It has many advantages, such as low-noise and low-vibration operation. But especially in dismantling needs, where mostly smaller -less powerful- demolition machines are used, thanks to the BOOSTER technology you still achieve the high power level and power needed in demolition work."

SAES offers, both with VTN and Epiroc, the right know-how, support and service.

More with less

"A real improvement in the efficiency of excavators," Henk believes. "It's a challenge to do as much work as possible with as little plant engineering as possible. That's what VTN is good at and what we as SAES also stand for." The HP series has a lighter structure but is equally resistant and offers much more strength in its cutting phase. Another added advantage is that with VTN's basic machines, the variable jaws of the VTN MT and VTN CK Combi cutters can be quickly interchanged. "That," Henk continues, "and the synchronous jaw movement system contribute to short work cycles." A top product from an A-brand, in other words. "Certainly," says Henk and wants to add, "investing in quality material, at the bottom line, only makes money in the end. Because with a top product and the good service offered by SAES, you have a golden combination. Our specially equipped service vans on location can minimize downtime and experience shows that good solid products last years longer thanks to good maintenance. So we still provide service on equipment that, from an accounting point of view, has in fact been written off a long time ago ... because from a technical point of view they can still last for years," concludes Henk.