'Subsidy is the death knell for faster transition'

Netherlands at risk of losing pioneering role

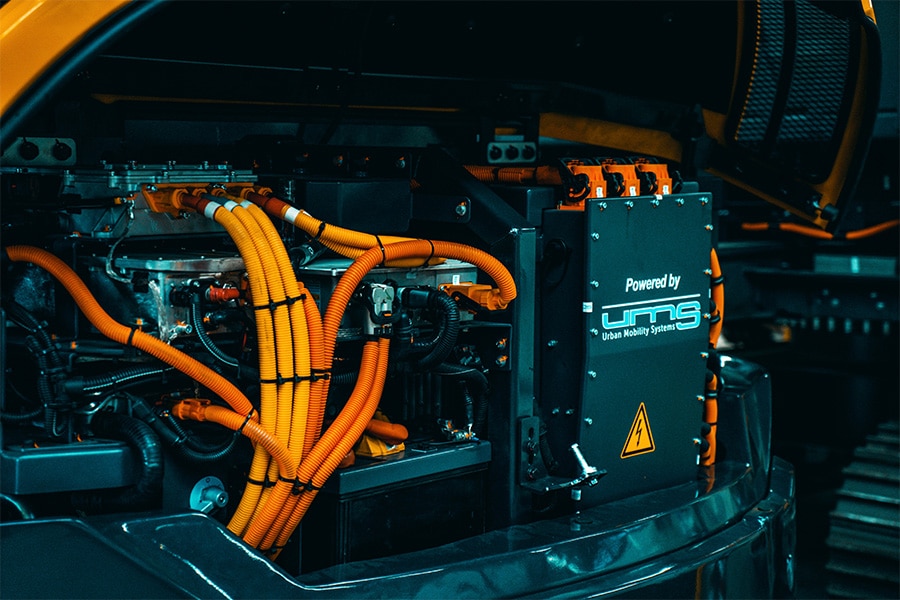

Lars Kool, founder/CEO of Urban Mobility Systems from Oss, is pretty much considered the founder of construction equipment electrification in the Netherlands. His company has so far built more than five hundred emission-free machines for leading brands such as Liebherr, Bobcat, Hyundai, DAF, Dynapac, Junttan and Knikmops. From compact wheel loaders, excavators or telehandlers to large crawler excavators, cranes and piling rigs. Delivering quality, guaranteeing safety and sharing knowledge are our watchwords.

We speak to Lars when he has just returned from America for a visit to the prestigious SEMA Show in Las Vegas. The enthusiasm splashes off immediately. The out-of-the-box thinking that is commonplace in the land of unlimited possibilities is right up Lars' alley. When he started Urban Mobility Systems in 2016, he could never have imagined that within a few years, the company would extend its tentacles to every corner of the globe. Stubborn as Lars is, he chose to walk his own path. That is precisely what has brought UMS this far. A week after America, Lars travels to Dubai, and soon the technology trade show CES is on the schedule again.

Because of the nitrogen issue, the idea quickly arises that the Netherlands is the epicenter when it comes to electrification of construction equipment. How do you view that?

Lars: "The 'real' manufacturers are not looking at the Netherlands; we are too small a market for that. Of course, it is interesting to see our country serving as a testing ground for the rest of the world. As UMS we can thus gain a lot of experience in a relatively short time with sustainable battery-electric powered construction machinery and vehicles from renowned brands such as Hyundai, DAF, Liebherr and Bobcat."

Should the cooperation with AIH Group and the commissioning of a brand new battery plant in Arnhem ensure a new growth spurt?

"AIH works for big brands like Mercedes, BMW and Porsche. It's a huge company. You can't choose them to work with; they choose you. Based on my vision of quality and safety - two core values embedded like DNA in our operations - AIH stepped in. With their cooperation, we will be able to build 300 conversion kits by the end of this year, and once the new production facility in Arnhem opens, that number will be increased to 3,000 kits. This is sure to succeed, as they have a track record of successfully delivering complex, challenging projects. As a global collective, AIH offers a lot of added value, providing a springboard to conquer the rest of the world."

Earlier this year, a collaboration with Ampowr on state-of-the-art energy storage systems was already established, and in partnership with 3ME Technology, UMS Australia was formed. Do the plans extend that far?

"Together with AIH, we are exploring the possibilities of setting up UMS production sites elsewhere as well. This has already been anticipated in recent years through various joint ventures. Following in the footsteps of the United Arab Emirates and North America, we now want to spread our wings in Australia and Argentina. This choice is as surprising as it is obvious. These are the producers of raw materials for batteries. That way we are not dependent on China and can sail our own course."

A course that should bring UMS (even) more international recognition?

"By operating globally, we are an attractive supplier to major manufacturers. After all, that is what we as UMS primarily focus on. Nothing against conversion companies, but I believe more in OEM products. Not only for acceleration, but also when it comes to dealer service, brand warranty, software updates and trade-in value. End users live too much in the now instead of looking at the big picture."

Explain that.

"The purchase of an electric machine often hinges on obtaining a subsidy, but in my view it can easily be done without this extra. This can be done, for example, by taking the batteries out of the purchase price and leasing them. You can apply for an EIB subsidy for that. Bare it is even cheaper than a diesel version. Then you still have the possibility of using the MIA/Vamil scheme. Add to that the lower fuel plus maintenance costs and the fact that you can easily run it two years longer, then the TCO is significantly more favorable."

The subsidy pot of 1 billion euros through 2030 for Clean and Emission-free Building is better spent?

"Absolutely! In fact, I think the SSEB regulation hinders rather than accelerates the transition. Our country is in danger of losing its pioneering role as a result. This is mainly because this subsidy is not available to everyone, which means that some benefit maximally and others are left out. In other countries, the money is not put into the purchase, but into the hourly wage. Those who work emission-free simply earn more. I suggest that the subsidy should be used on the procurement side. On average, an excavator runs 1,600 hours annually. Suppose you could then rent it out for 50 euros more, paid for partly by the client and partly from the SSEB pot, that would generate 80 grand a year. Then tomorrow everyone will order an electric machine and the whole chain will benefit. Now both the developer and manufacturer and end user can apply for subsidies for one and the same machine. That is economically irresponsible. The pot is thus emptied by a relatively small group, making it impossible to also get small and medium-sized enterprises to join in the transition, which is precisely what is essential to really get it going."

That sounds worrisome...

"The transition to zero-emission construction is mainly floating on the cork called subsidy. The current regulation is the death knell for a faster transition. We are already producing more kits, than converters in the Netherlands build electric machines annually. So it makes perfect sense to look across the border, especially now that other countries are catching up. Electrification seems to be moving faster in many countries than it is here. This is not so strange, because we have already eliminated many teething problems for them. Not only technically, but also in terms of charging infrastructure and power failures."

There you say. Opponents will cite that to argue for HVO diesel or - if it must be zero-emission - hydrogen.

"I believe for 100% in hydrogen, but in specific applications. UMS, through Nuvera, a subsidiary of Hyster-Yale, builds in fuel cell engines for trucks, buses, ships and generators. It's an ideal energy carrier for stationary applications, not for machines in the field. Besides posing considerable logistical and safety challenges, it breaks down irrevocably in dusty environments. For machines up to, say, 35 tons, I would always go for electric. Beyond that, hydrogen may be an option, although it's barely affordable now. A crane or piling rig with hydrogen cells, I can still see that. Still, H. van Dieren proves with the Junttan PMx22e that it can be done just fine electrically. That foundation machine has been driving piles into the ground for over a year with zero failures. I'm super proud of that."

In past years you constantly hammered on security, but by now everyone seems convinced of that.

"The collaboration within ENI (Emissionless Network Infra) has meant that the bar has been set high. Customers also appreciate it when you are transparent and honest, because clearly not everything has gone smoothly. All partners within the chain work closely together and exchange a lot of knowledge. In order to multiply, you must also be able to share. It makes no sense to hold all the cards up to the chest, because it is a common interest to accelerate the transition to zero-emission construction."