Three construction team projects serve one purpose

More water into the hinterland

Southeastern Brabant and Northwestern Limburg depend largely on the Peel canals for water supply and distribution. As a result of increasingly dry summers, there is a water shortage on these higher sandy soils during the summer months. So more water must be brought into the area. And for this purpose, not only have the main arteries been widened, but the entire system of dams and pumping stations in the hinterland has also been adapted to this higher capacity. Contracting company Vissers Ploegmakers was responsible for the 'Optimization of the Peel Canal Water Supply' program, consisting of a combination of three separate construction team projects.

Before the optimization, a maximum of 3.4 m3 of water per second was supplied from the Meuse to the entire system; now this has been increased to 5.4 m3 per second. "A water agreement for this was already concluded in 1994 between Waterschap Aa en Maas, Waterschap Limburg and Rijkswaterstaat," knows Ron de Mol, project manager at Vissers Ploegmakers. "So now that plan has come to fruition with a clear distribution key: Waterschap Aa en Maas is taking care of the upgrading of the canals, while Waterschap Limburg is taking care of the task of adapting all the engineering structures. Vissers Ploegmakers prepared all projects in a construction team with both water boards in order to achieve the most optimal end result with the knowledge and experience from the market."

Underwater sludge depot

To handle more water at all, an upgrade of the Peel canals was necessary, more specifically the Deurne Canal and the Helena Canal. "Due to various (environmental) factors, the canals were suffering from overdue maintenance and were fairly silted up," says Ron. "They needed to be 'dredged' considerably. In addition to removing more than 100,000 m3 of silt over a length of 21 kilometers, the embankments were repaired to prevent nutrient-rich Maas water from running into the Deurnese Peel and Mariapeel raised bog areas, both Natura2000 areas. In addition, 4.5 kilometers of beaver-proofing has also been installed." Working in the Natura2000 areas meant that Vissers Ploegmakers could not simply drive the contaminated sludge out of the area. "Together with Smals Dredging and Kurstjens, we devised an innovative method in which the sludge was pumped to an underwater depot at four strategic locations in both canals outside the Natura2000 area. Such an underwater depot involved a strip about 100 meters long and 10 meters wide (the canal is 15 meters wide, ed.) with several basins. First, sand was extracted from the silt, which in turn was used for the closed-soil quay rehabilitation. Then a thickener was added to the sludge to make it thicken faster and allow it to be disposed of."

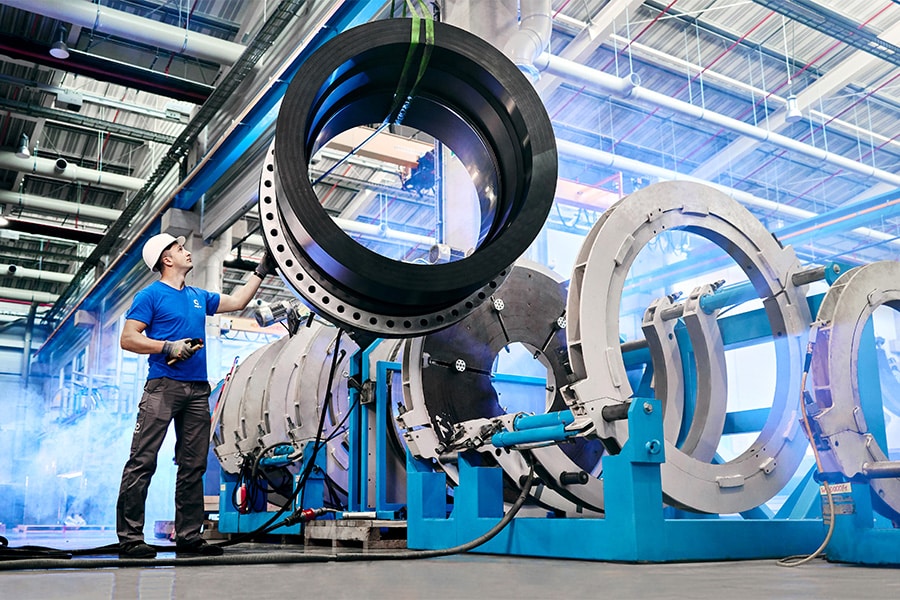

New dams and pumping stations

Artworks in the canals and the existing water system in the hinterland have also been adapted to the higher capacity. "A total of seventeen engineering structures (weirs, pumping stations, inlets) have been widened and modernized to allow more water to pass through," says Ron. "The weirs have all been automated and remotely controlled. Where there was already a power supply, we used the existing network. In those places where that was not the case, we used solarmasts from Modderkolk. HC Waterbeheersing in turn was responsible for the delivery of ten new weirs and two overflow pits."

Even during realization, the supply and discharge of water into the Peel Canal and the water system behind it is of course important. "Therefore, during the realization, depending on the location, we either dug a temporary bypass or constructed a temporary siphoning installation. Also special was the section where the Peel Canal runs through the Vredepeel defense base. Under the runway, the three tubular culverts, each 300 meters long, were completely silted up and silted up and were cleaned 'in the wet' using a special cleaning technique with jet pumps and sliding windows and inspected with an underwater drone."

First polder in Limburg

The final construction team project within the program involved water management in and around Griendtsveen. "For 20 years, work has been done in this high moorland area to retain as much water as possible. This caused the village of Griendtsveen to slowly begin to be inconvenienced by rising water levels," says Ron. "In order to properly control the water level in the area and limit flooding in the village, we firmly adjusted the water system. Within this project, water courses were modified, culverts and siphons were constructed and two new pumping stations were built to keep the first polder in Limburg artificially level."

Meanwhile, all three projects have been completed by Vissers Ploegmakers and the hinterland of southeastern Brabant and northwestern Limburg is more resilient to dry summers.