Modeling with 3D and Augmented Reality

Complexity requires prior understanding

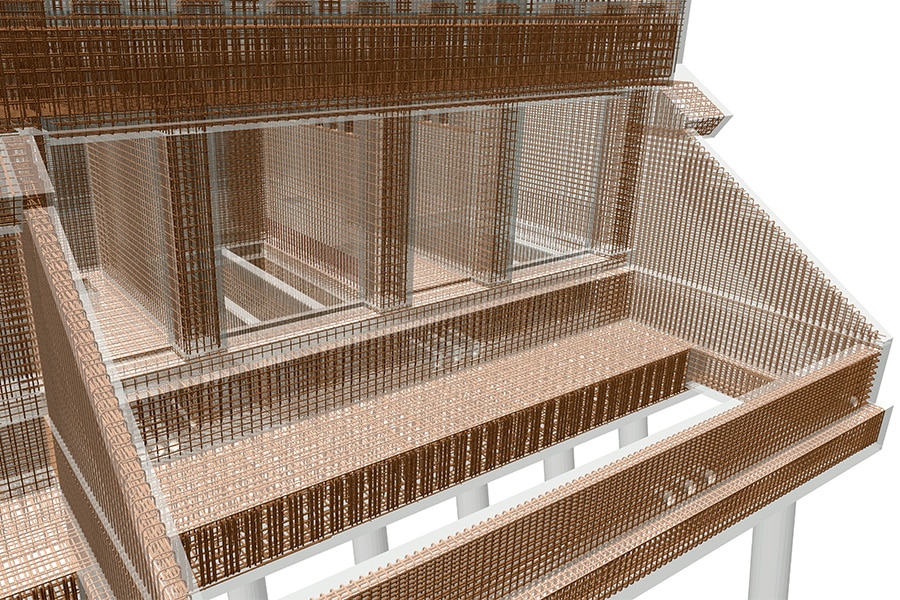

For the renovation of the Minervapassage and the construction of the Brittenpassage at Amsterdam Zuid station, a total of some 3,000 tons of reinforcing steel is needed for the first phase. Given the complexity of the work, safety and determining the correct reinforcement pattern in advance is important. Diepstraten Wapeningstaal therefore applies 3D and Augmented Reality.

Diepstraten Wapeningstaal is a renowned company in the civil engineering sector as well as in industry. It has been applying its expertise and craftsmanship in the field of reinforcing steel to larger infrastructure projects for almost ninety years. That's where the expansion and renovation of Amsterdam Zuid station, part of Zuidasdok, now comes in. "For the project we model the reinforcement in 3D," explains director Ed Schipper. "That is also immediately our strength; we have all disciplines in-house, from work planner to 3D modeler to executive staff on the construction site. 3D is indispensable in our profession today. We have immediate insight into whether the construction as we have conceived it is actually safely feasible and complies with the applicable standards. Thanks to the 3D impression, you have insight into aspects such as "which scaffolding is needed where?" and "what is the best working method for applying the reinforcement?". Especially with the expansion and renovation of Amsterdam Zuid station, where a lot of reinforcement is needed, the intensity is high and the working space is sometimes limited, 3D models are indispensable. We think along with our clients from the moment the reinforcement data are known. We work closely with Bouwcombinatie Nieuw-Zuid in order to achieve an optimal design. This cooperation is very pleasant and in the work so far, this working method has certainly proved its worth."

Virtual tour of design

In addition to 3D, Diepstraten also uses Augmented Reality. "Our employees have a special app that allows them to scan a flat drawing on their tablet or phone. They are then shown a 3D model and can virtually walk through the design. This gives them a good idea of the final product. In addition, each 3D model comes with a step-by-step plan that allows our executive staff to apply the construction step by step. An important plus point especially since the reinforcement patterns for Zuidasdok can be intensive."

SCL-4 certification

The logistical complexity of working in the Zuidas requires a lot of attention to safety. Diepstraten therefore has its own Safety & Quality department and even a special DWS safety team. That Diepstraten takes safety very seriously is shown by the fact that they have obtained SCL-4 certification. "We also have our own safety app," says Siham Tajjiou, responsible for quality and safety. The DWS Safety App was specially developed by Siham for the employees. "Because of all this attention to safety and well-being for our people, our employees' safety awareness has increased tremendously."