Unique combination of sealing principles make self-closing barrier leak-tight

Waterproofing a dam is the "most normal thing in the world," so to speak, for Trelleborg Infrastructure. However, this does not apply to the Float Barrier® at the dyke reinforcement Steyl - Maashoek. Other forces are at play here. Literally and figuratively. Nevertheless, Trelleborg's experts know how to manufacture a custom rubber seal for this "daring feat" as well, using an unprecedented combination of sealing principles.

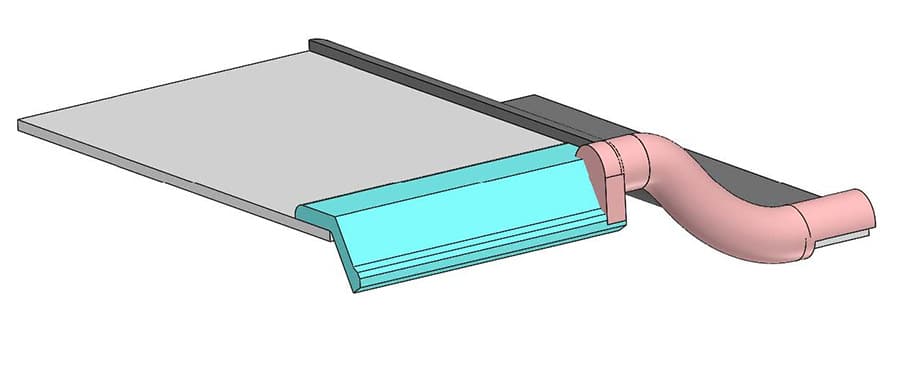

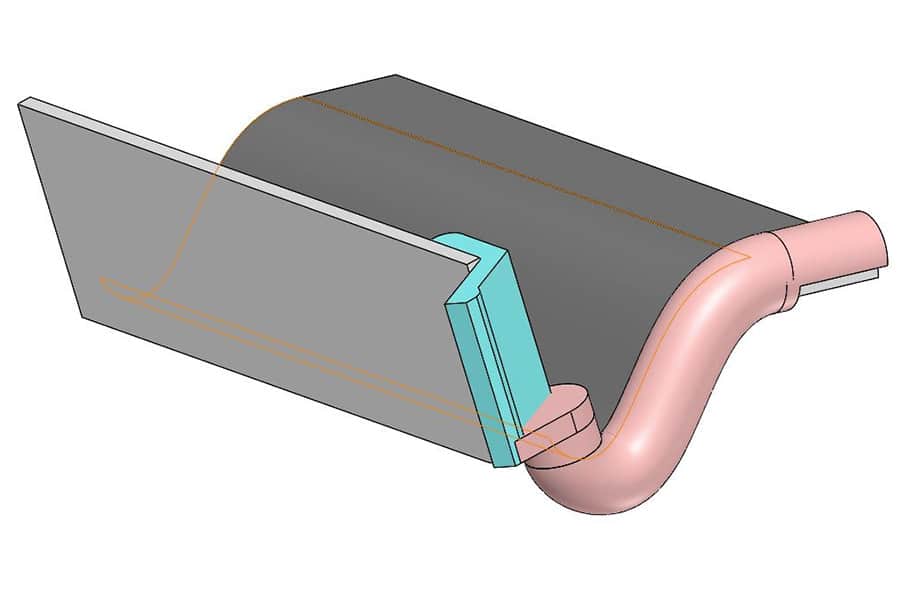

The Float Barrier® at Steyl - Maashoek consists of a series of steel valves that autonomously move upward from a concrete container as the water level rises. "We were asked by Hollandia Infra (as a combiner of the Dike Zone Alliance) to shine our light on the sealing principles required that would ultimately make the barrier sufficiently leak-tight," begins Bob Rijnders, Global Sales Manager at Trelleborg. "It basically involves three different rubber seals: between the steel valves themselves, on the underside between the valves and the static bucket structure and a seal for the corner points."

Difficult nodes

Trelleborg is used to realizing custom rubber seals. "You can't get the products we supply off the shelf anywhere," says Olivier Schuringa, Design Engineer at Trelleborg Infrastructure. "We feel comfortable enough to go into a design process together with the customer, in this case Hollandia Infra, on a project like this to ultimately create an object such as now the Float Barrier® sufficiently leak-proof. That is what we are good at and is where our added value lies." Nevertheless, it took the Design Engineers at Trelleborg a lot of brainpower and calculation to make the difficult junctions, especially at the corner points, leak-tight according to the requirements set by Waterschap Limburg.

Corner Solution

Trelleborg provides several sealing principles. "For the Float barrier® we combine two sealing principles, namely a membrane seal with a self-activating seal," Bob explains. Olivier adds: "The great thing about this project was that Hollandia Infra engaged us at an early stage so that we could optimize the design together. It resulted in a membrane seal between the concrete container and the valves, while between the valves themselves a different type of membrane seal was chosen that can handle more movement. We solved the waterproofing at the corner points by a combination of a membrane and lip seal with a flexible 'tendon' attached that is compressed as the valve moves upward, thus achieving the seal." Compression of the corner piece listened more closely than initially expected. Compressing the 'tendon' evenly over the sealing surface was therefore a challenge in itself, but was solved with a robust design through the combined knowledge of Trelleborg and Hollandia Infra."

Wonderful interplay

The sealing methods were extensively tested in a mock-up. "We had many test moments where we managed to optimize the concept further and further," Bob reflects. "A nice interplay between the expertise and specific design of Hollandia Infra with the theoretical and practical knowledge of rubber of Trelleborg Infrastructure as well as the solution orientation of the designers." Trelleborg will also handle the installation of the seal. "We are involved in the project from design to implementation. The seals are delivered in parts. Where necessary, fitting pieces are measured and vulcanized on site according to the design, so that the different types of rubber seals eventually form one integral system with a life span at least equal to that of the water barrier."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Trelleborg Ridderkerk B.V..

Contact opnemen

Contact opnemen