Sustainable use of foundations overpasses and bridges

In construction, it is increasingly common to consider whether the pile foundation already in place can be (partially) reused during reconstruction, expansion or complete new construction. In infrastructure, on the other hand, it has not previously been applied on a large scale. Thanks to Fugro's expertise in the widening and deepening of the A9 motorway between Badhoevedorp and Holendrecht (BaHo), this will now change for at least five viaducts.

"Because of the difficult weak subsoil, especially in Amstelveen, we, as a reputable party, were asked by VeenIX to support them with the geotechnical soil testing and consulting," begins Diederick Bouwmeester, Manager Sector Infrastructure at Fugro.

Geo-risks

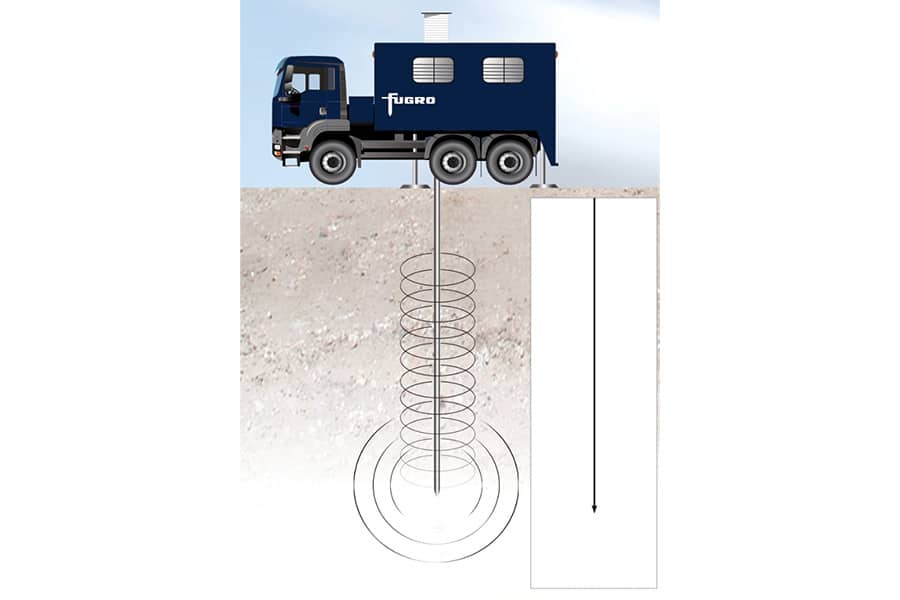

"To do this, we did an analysis on the ground surveys already available and those in our archives," Bouwmeester continued. "Around Amsterdam we have done a lot of research in the past. We then listed this and estimated what additional soil research would be needed with probing and drilling, to get a good picture of the geotechnical soil parameters. In addition, it was considered whether additional geological investigations were needed. It is important to find out whether you are dealing with multiple geological deposits, which means that different parameter sets have to be used.

In this project, Fugro surveyed more than 2,500 sites with probing and drilling. "Based on this, we created a basic geotechnical report and a 3D subsurface model, or 3D ground information model (GIM), which everyone can work with. Together with the Department of Public Works, we are therefore the interlocutor for geotechnical engineering within VeenIX and all the design firms and subcontractors."

Furthermore, Fugro made another proposal for the monitoring work, so that during the execution of the earthworks, anomalies can be closely monitored by means of pocket beacons, pore pressure gauges, inclinometers and monitoring wells and directly interpreted to the design requirements.

Calculation rules

Eleven viaducts within the project will be demolished and rebuilt in a widened form. A requirement from the Department of Public Works was to reuse parts of several viaducts. "In the bid design, VeenIX made an overview of the foundations that were eligible for reuse and whose feasibility had to be tested during the project," says Johan Schuringa, Geotechnical Consultant at Fugro. "In particular, the goal was to reuse foundations from the 1960s and 1970s. But these were calculated using different standards than what current foundation design must meet. Special calculation standards have been established to test the old piles, the most important condition of which is surely that the pile load does not increase by more than 15% (see NEN8707). Otherwise you have to design according to the latest standards and then you will never come out with regard to the bearing capacity of the foundation piles. Especially because in 2016 the calculation rules were tightened and the pile factors (for the pile point bearing capacity) were reduced by 30%."

Pole bearing capacity

So when possibly reusing existing foundation piles, you will first have to see if the pile load increases by less than 15% in the new situation. "That's actually a question for the structural engineer," Schuringa says. It has now been concluded that the pile foundations of five viaducts can be (partially) reused, and Fugro has already fully calculated the concept for structure four (KW4 - a viaduct on the west side of Amstelveen, ed.). For KW4, there was intensive contact between the structural engineer and Fugro's Geotechnical Department. It was estimated that the total weight of KW4 in the new situation would increase by 11%, within the margins. Mind you, the viaduct will be widened from 27.5 to 50 meters. "So the first hurdle was taken, but then we just fell short of the pile bearing capacity in the first design phase. Still, we had enough leads to continue, because we could always take additional control measures."

Additional management measures

If the bearing capacity is not met, as is the case with almost all existing overpasses on the A9 BaHo, it is permissible, for example, to conduct additional probing to further determine the homogeneity of the subsurface. "A sounding only provides information about one point. The rationale behind this measure is that if you conduct multiple investigations (read: soundings) you can say something about the homogeneity of the subsurface with more certainty," Bouwmeester further explains. "In the calculation rules, a certain ξ-factor, a correlation factor for the number of soil tests, is included for this purpose. This often becomes more favorable with more soil tests, resulting in a more favorable/better bearing capacity. So you can attribute additional bearing capacity to the existing pile foundation. So additional soil testing pays off."

Stiffness differences

The old piles, together with the new piles, should eventually form the foundation for the new and widened viaduct.

"However, old piles are a lot less stiff compared to new piles because they used to be driven on breech to just into the Pleistocene sand," Schuringa knows. "With the current calculation rules, the new piles have to be a lot deeper to achieve the required bearing capacity. That creates quite a lot of stiffness differences in the foundation and that can have a negative impact on the force transfer. That all has to be calculated as well. In addition, the prevention of installation damage or temporary reduction in load-bearing capacity of the old foundation due to the installation of the new piles must be taken into account. These are important points of attention in the execution."

Control probes

Fugro had access to old specification drawings from the 1960s/70s on how the overpasses were built and where the piles were located. Whether they were braced or to lead, the dimensions and the pile tip level. "Experience shows that the drawings don't guarantee whether it was actually built that way in reality," Bouwmeester says. "Piles that qualify for reuse we want to be able to assess properly so we can be sure they are at depth to the Pleistocene sand. This can be done in several ways, and at KW4 it was done by probing with a so-called magnetometer taper. A special cone that detects the reinforcement in the pile. For this it was necessary to carry out the probing within a distance of one and a half meters from the pile. Since the piles were mostly driven on braces, that too was a matter of good puzzling. Wherever it was at all possible, we carried out control probes and thus demonstrated with reasonable certainty the realized fence levels."

In the end, KW4 managed to include all 208 old piles in the Final Design of the new foundation. This, according to Fugro, will also save about 200 new piles which is equivalent to 1,200 tons of CO2-emissions (which is equivalent to about ten transatlantic round-trip flights). Apart from the fact that every pile that does not have to be installed saves in concrete, reinforcement, transportation and installation: thus time AND money. "And that's just for KW4," Schuringa stresses. "There are four other viaducts whose piles will be (partially) reused, including the bridge over the Bullewijk and the bridge over the Amstel River." ■

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Fugro.

Contact opnemen

Contact opnemen