Barriers to full digitization finally fall away

Digitalization seems to be the magic word of our time. Easily monitor and manage the entire construction site? It can be done, completely digitally. The desire to do so is great, but so is the threshold to actually take action. It is therefore real work for specialists, who bring software, hardware and Cloud connectivity together into a smart whole.

Thanks to specialists who make every effort to keep up when it comes to the latest technologies, machine control in all its complexity is available to everyone. Optima Infra is one such specialist. They work with Infrakit to make intelligent project information available in real-time. This innovative approach results in faster project completion while improving quality, reducing errors and decreasing delays, resulting in cost savings.

Cor Lont, director of Optima Infra.

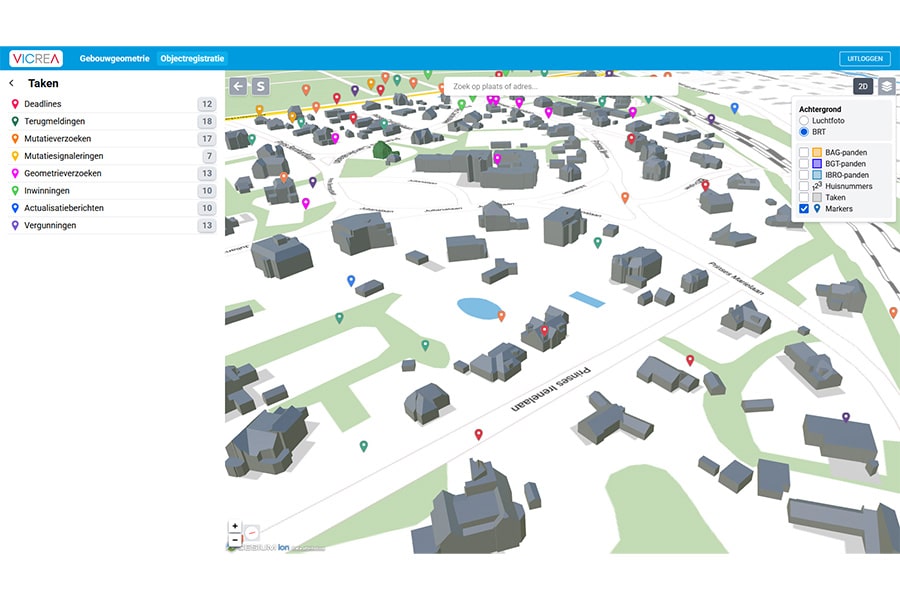

Connecting participants and sharing data easily Project participants are connected by Infrakit in a shared information management system. Open formats and Cloud technology create an optimized information flow that enables collaboration for all stakeholders within an infra-construction project. Cor Lont, director of Optima Infra, says, "Infrakit has an intuitive visual approach for accessing all information on the map or in automated reports. This ensures that the entire team works with common goals and has up-to-date information easily in hand, even on mobile devices. 3D machine control is often an underdeveloped child, many parties struggle to master all brands of machines. It is precisely Infrakit's independence in this that suits us. Open formats and Cloud technology enable interchangeability, accessibility and accessibility. Very comfortable, it works particularly fine."

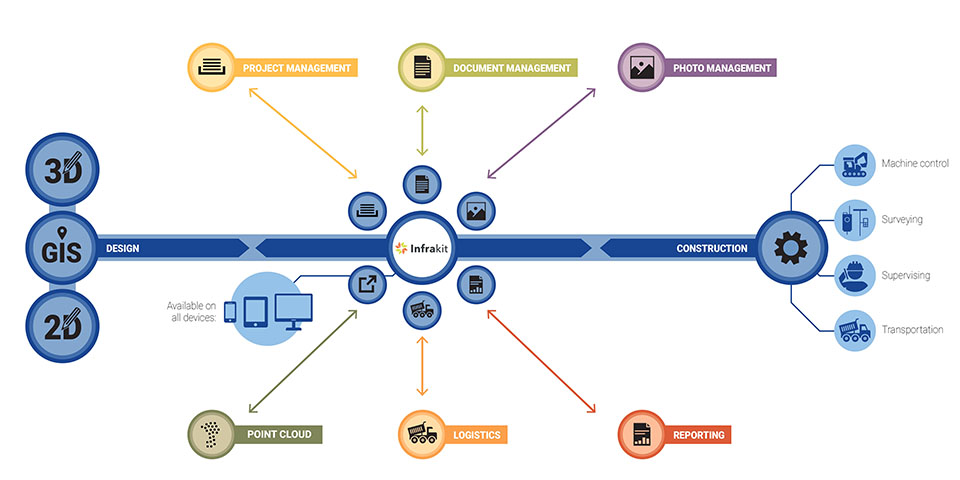

Schematic representation of the digitization process.

From office to cabin: everything digital and in 3D Optima Infra is a well-known player in the infrastructure sector. With a nice portfolio of assignments involving all kinds of surveying activities - for example, the creation of 3D models of projects or volume calculations - Optima Infra manifests itself as a specialist. Equally important, however, is their expertise in machine control. Lont explains: "We supply and install the hardware required for this purpose on the machines. Think of equipment such as control screens, GNSS receivers and sensors that are indispensable. Of course, everything is neatly installed and calibrated by us. When everything is up and running, the operator can see the relevant 3D models on his own screen."

Brand independence is a USP

Optima Infra offers its services-preparation, installation and support-for all brands of machines and machine controls. Lont is clear about it: "Working independently of any brand is a Unique Selling Point and allows us to serve almost anyone. We can only do that thanks to Infrakit. With it, we can initiate the entire digitalization of the construction process and easily remove all barriers for our customers."

Infrakit can enable the entire digitization of the construction process.

So in terms of compatibility and connectivity, Infrakit is imperfect. The package works Open Source and is therefore brand-independent. As a result, Lont is extremely enthusiastic about it: "Infrakit can be connected to other software, whether it's administrative packages, or remote machine control."

InfraBIM rollout

Optima Infra has its headquarters in Friesland, but now has a branch office in Didam. "We are serving more and more German customers, after all," Lont outlines. What about servicing Infrakit? "We take care of that together with Infrakit, but the main focus is always on us as a reseller." Lont gives another hint: "We are now rolling out InfraBIM, which allows data and processes to be coordinated. InfraBIM is BIM but completely focused on the Infra sector. Infrakit is now positioned as machine control, but it is certainly also ideal for inventory and data sharing. The nice thing is that with it, everyone within a project speaks the same language. In a nutshell: Infrakit provides the ability to share data, InfraBIM tells you how to share that data."