One-stop shop for testing, inspection and certification

Normec QS has been the independent one-stop-shop in testing, inspection and certification for more than twenty years. As part of Normec, a leader in testing, inspection, certification and compliance, its scope has expanded considerably in recent years. In addition to foil constructions in sunken layers, at landfills or in seals with AEC bottom ash and steel slag, Normec QS can, for example, also make statements about the residual life of plastic pipe systems and constructions.

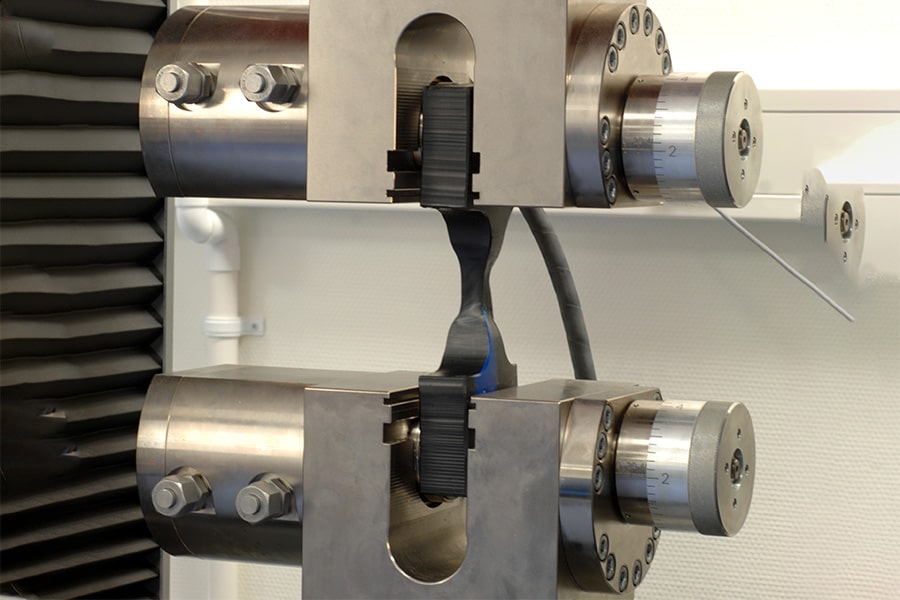

In addition to landfills and the sealing of steel slag, foil structures are increasingly being used in the deep construction of road structures. In many cases, it is a more economical and sustainable alternative. "And in this we are a one-stop shop," says general manager Iljo Fluit. "For foil structures, for example, we act as an accredited inspection body during construction and perform destructive tests on plastic welded joints in our own laboratory accredited for that purpose. We are also allowed under accreditation to make a statement about the expected residual life of foil structures due to the fact that we have our own accredited long-life behavioral expert in-house."

Knowledge partner

Normec QS also maintains a one-stop-shop principle for plastic pipework. "We provide personal certification of both plastic welders and welding supervisors, visual inspection during construction (verification of welding parameters, visual inspection of fabricated welded joints), destructive testing of both randomly tested field welded joints and representative test welded joints, and ultrasonic NDT testing (ToFD for mirror welding and PAUT for electrofusion welding)," Fluit lists the tasks and continues: "Uniquely, our services fall under intellectual property as well as accreditation. In addition, we profile ourselves emphatically as a knowledge partner; we take our responsibility in the chain by actively participating in standardization committees and in industry associations. In this way we can anticipate developments in laws and regulations and proactively unburden our customers."

Residual life determination

Normec QS has developed a methodology for determining the residual life of plastic piping systems. "We have developed a practical and effective research method to test the degree of aging and determine the expected residual life under the same usage conditions," Fluit clarifies. "In many cases, this demonstrably extends the lifespan by many more decades and can postpone replacement investments. The method is based on a scientific foundation by TNO."

Geoelectric measurement

Also accredited and with ministerial recognition is the GEM2 system developed by Normec. "We use it in particular to issue a Declaration of Impermeable Provision on foil structures. Again, a unique methodology, because not only is a 'close-tight measurement' performed, but also the location of the leakage is located after performing the geoelectric measurement."

Since joining Normec, we are able to serve our customers in a much broader sense, Fluit summarizes. "For example, we make grateful use of the services of our sister organization Normec Certification (see article elsewhere in this magazine, ed.) and of Normec OWS in Ghent (B), which does a lot of research into, among other things, the biodegradability of plastic materials." Normec OWS is on the front line in the development of new analysis methods and performs sustainability analyses such as LCA (life cycle analysis), carbon footprint, EPD (Environmental Product Declaration) and PEF (Product Environmental Footprint).

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Normec QS.

Contact opnemen

Contact opnemen