Colorless binder in Warm Mix color asphalt

A high-quality, circular and safe application

The Netherlands has one of the most densely branched road networks in the world, of which some 130,000 kilometers are paved roads, mostly made of asphalt. In order to ensure a sustainable and safe road network in the Netherlands, a lot of hard work is being done on solutions and improvements of the asphalt, its service life and maintenance, among other things. Latexfalt and Ooms Products are the leaders in innovation processes and doing research in the field of asphalt and bitumen. "We see innovation, sustainability and cooperation as the way to success for road construction, among others," says Dr. Ir. Eyassu Hagos, senior R&D specialist at Latexfalt.

Recently, Latexfalt in cooperation with Ooms Products BV - Sealoflex conducted research into the use of colorless binder in Warm Mix color asphalt. The lead-up to it and the main conclusions from that research can be read here.

Colored pavements

In the Netherlands, and increasingly abroad, colored pavements are used. Often this is to promote traffic safety by adding accents to the road, such as the well-known red or yellow colored bicycle lanes and at intersections, traffic squares and speed bumps. It may also be that colored pavements are applied for aesthetic reasons, or to improve the well-being of residents by reducing heat stress in inner cities. Lightly colored road surfaces also contribute to CO2-reduction by requiring less lighting.

Different techniques

The way colored pavement is achieved can vary; from painting (painting) the road surface to applying an epoxy resin coating or using colored crushed stone in combination with synthetic pigmentable (colorless) binders. "Each application has specific advantages and disadvantages both in terms of quality and service life. The various techniques are also clearly different from each other in terms of cost," says Hagos. According to him, bituminous surface treatment with colored crushed stone is the cheapest. "However, the weather conditions during road construction determine the service life to a large extent. If the crushed stone does not bond well with the emulsion, when laid in poor weather conditions, for example, the service life is very short. The same applies to an epoxy resin coating, which can only be applied to a dry surface." Hagos knows that colored asphalt, produced with standard black bitumen and lots of color pigment, is regularly used because of its lower (initial) cost compared to asphalt with a colorless binder. "A disadvantage with this, however, is that the color is much darker than what you can achieve with a colorless binder. Moreover, due to the large amount of pigment in black bitumen, the quality seems to decrease compared to standard black asphalt." A possible cause of this may be that the pigment used is not compatible with certain types of bitumen, according to Hagos. "This may even manifest itself immediately after asphalting in the form of an almost non-compactable 'dry' asphalt mixture."

Best result with pigmentable colorless binders

A colored hardening with a (high-quality) colorless binder has been shown in practice to yield the best results with a long service life, according to Ir. Kees Plug, specialist at Ooms Products. "Colorless binders have the advantage that a bright color can be obtained with relatively little pigment. This is in contrast to conventional black bitumen with which a dark color is still obtained with a lot of (powder) pigment. However, doubts have arisen in the market about the quality and workability of colorless binders and whether colored asphalt with a colorless binder is circular and sound from a health and safety perspective. This is because of possible emission of fumes during production and processing." The recent research conducted by Ooms Products together with Latexfalt shows that these doubts are unfounded and that a high-quality hot mix asphalt can be produced responsibly with a colorless binder. In this article we will discuss the specific aspects of pigmentable colorless binders and how they can best be applied in practice, also with regard to health and safety aspects. We will do this using a simulation test in the laboratory. The circular aspects of colored asphalt will also be discussed.

Visual inspections

But first, let's look at colored asphalt in practice. Because little research has been done on the properties on a laboratory scale and colored asphalt with a colorless binder is not CE-compliant, only visual inspections can give an impression of the performance of colored asphalt. "More research should be done on this," Plug believes. "We have, to assess the performance of colored road surfaces, looked at several locations with red asphalt in the Koggenland/Beemster region in 2019. Although the exact construction date of most locations is not known, it can be assumed that in most cases the asphalt has been there for more than 10 years. These visual inspections have shown that the damage pattern at locations where a polymer-modified colorless binder has been applied is limited.

Especially compared to the cheaper variants," Plug says. He concludes that, in the past, the unmodified variant was mostly often used in situations for which it was not suitable. "Such as at speed bumps, resulting in premature damage."

Thus, based on these (summary) visual inspections, it can be said that the best quality colored asphalt is obtained by applying colored asphalt with a modified colorless binder.

Specific aspects

"A synthetic pigmentable binder has similar properties to a conventional (polymer-modified) bitumen," Plug said, stressing that it is important, however, to use a high-quality colorless binder. "This is because the asphalt quality to be obtained depends on the type of synthetic pigmentable colorless binder applied. Because there is no standardization for colorless binders in the Netherlands, the quality can vary quite a bit. Therefore, there are unfortunately colorless binders available on the market with mediocre performance that are used for the wrong application. Therefore, an unmodified low-grade colorless binder may perform worse than a standard black asphalt. On the other hand, it appears that a good quality synthetic pigmentable colorless binder can at least meet the performance of a standard polymer modified bitumen (PmB), provided that the asphalt mixing and processing temperature are also well matched to it. "The resistance to fatigue and rutting is very high, so premature failure on mechanical properties is therefore not to be expected for this type of binder," Plug says. He acknowledges that although stiffness is lower due to the modification, this parameter is not normative for an overlay.

Asphalt mixing temperature

"As mentioned, the mixing and processing temperature of the asphalt is very important for the processing process and the final quality of the asphalt. It is therefore important to adhere to the supplier's recommended temperatures for the specific type of binder," Plug says. "Not only is the pigment itself sensitive to excessively high temperatures that can cause it to discolor, but excessively high mixing temperatures (180 °C) can also cause unnecessary emissions of asphalt fumes. For safe processing, these emissions must be as low as possible. Thanks to new developments, it is possible to produce colored asphalt with synthetic pigmentable colorless binders at a low temperature (120-140 °C) Warm Mix Asphalt (WMA) with similar emission fumes as a standard bitumen. In addition to saving gas, emissions of volatile compounds during production and processing will also be significantly reduced."

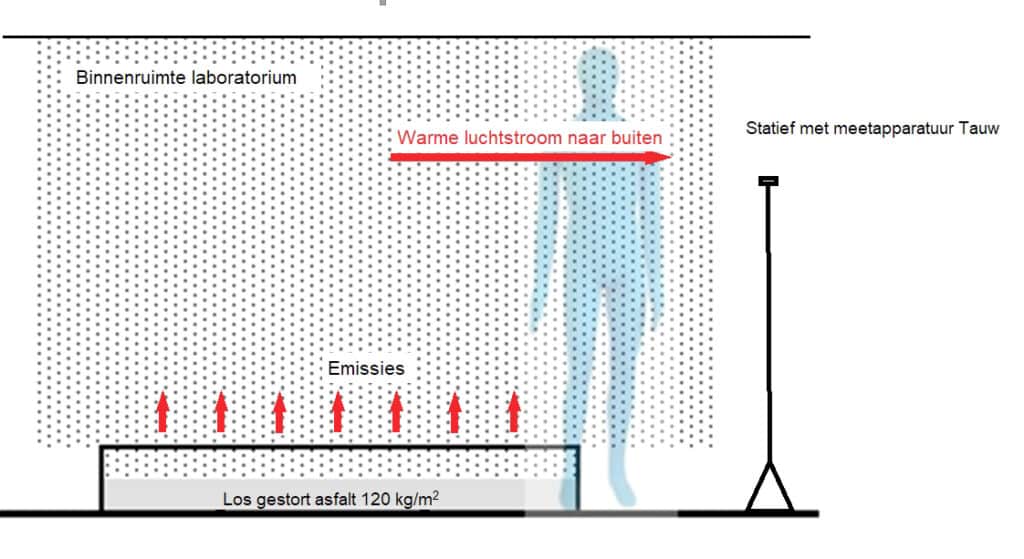

Laboratory simulation test emissions

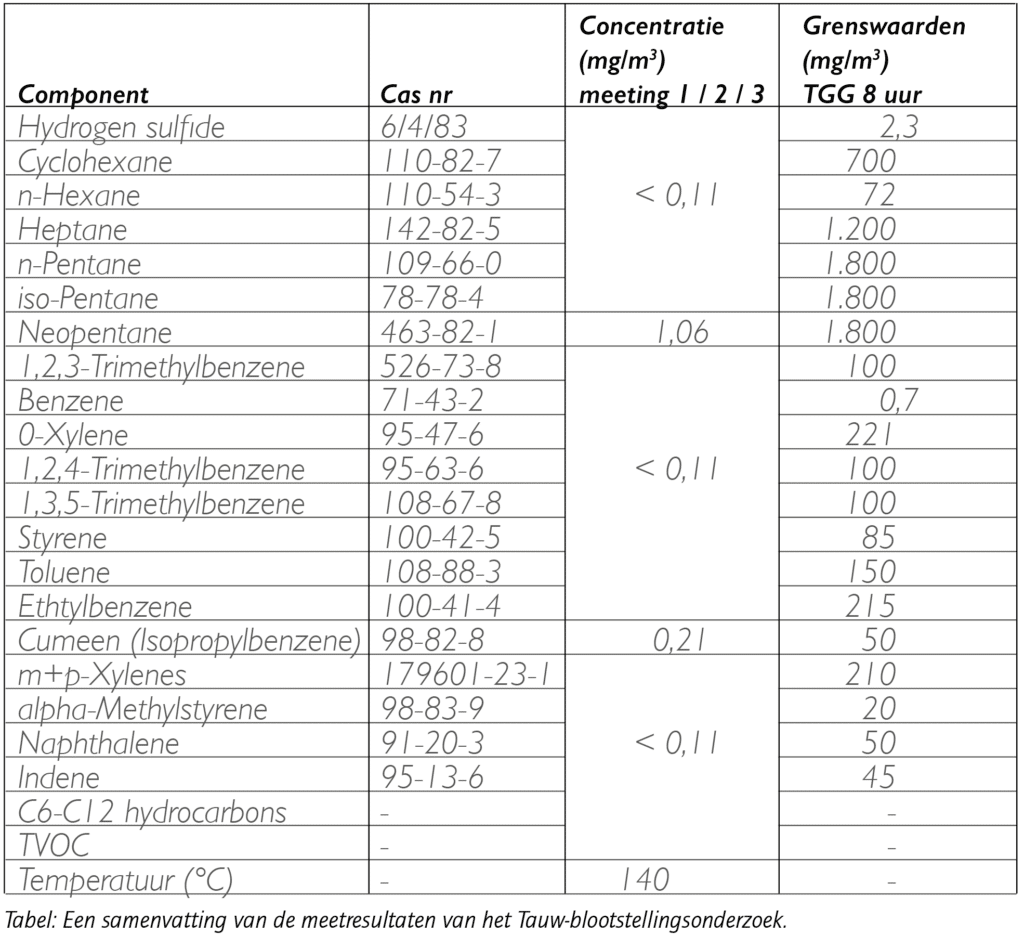

"We don't just say that, we naturally want to carefully substantiate it," Plug continues. "That's why we set up a simulation test in our laboratory to quantify the emissions during the hardening process for a red-colored asphalt mixture with a synthetic pigmentable colorless binder." The measurements show that even in a worst-case scenario (measurement in enclosed space), the limit value is not exceeded as time-weighted average (TGG). The measurement in the open space (simulation emission behind the asphalt spreader) shows that in this case the emission is in all cases below the detection limit and thus well below the limit value as time-weighted average (TGG). It can therefore be concluded that there is no health and safety problem in applying colored asphalt as Warm Mix Asphalt, because the emission of emissions, vapors and aerosols at these lower temperatures is minimal and well below the limit values as included in the occupational health and safety standards.

Tauw exposure study results.

The table below summarizes some of the measurements from the exposure study. The full results are included in the Tauw report.

Circular aspects of colored asphalt

Because asphalt is widely reused in the Netherlands in the form of partial recycling (PR) in new asphalt, the circularity of colored asphalt was also examined. "This showed that colored asphalt with a synthetic pigmentable colorless binder is in principle just as circular as conventional asphalt. Because of the smaller volumes of colored asphalt, it does present a challenge to reuse old colored asphalt in new colored asphalt. And it is not preferable to apply it in a standard (black) overlay, because of the different color crushed stone," Plug said. "However, low-grade reuse in standard asphalt sub-layers is something that can be done without much effort or problems. The quality of the new asphalt obtained to date is at least comparable to the quality of standard asphalt without PR material. This is because a colorless binder is fully compatible with (rejuvenation) bitumen and also still contains active polymers. Horizontal recycling of color asphalt granules can therefore certainly make a significant contribution to achieving road authorities' goals of achieving more sustainable asphalt mixtures. Unfortunately, for logistical reasons, color asphalt granulate is not currently kept separately at the asphalt plant. Should this be the case in the future, color asphalt could easily be produced from recycled asphalt as well.

Conclusion

With the right selection of materials and when the right production and processing instructions are applied, it is possible to produce colored asphalt in a responsible manner with a life span at least equal to standard (black) asphalt. The emission study of the processing of colored asphalt with a synthetic pigmentable colorless binder shows the following:

- Colorless binder is at least equivalent in quality to black bitumen, and has a more consistent quality;

- To obtain a bright color, the application of a synthetic pigmentable colorless binder is required herewith;

- Colorless binder has better compatibility with color pigments, the asphalt therefore has a longer life, which is also more predictable;

- The new generation of colorless binder (low temperature) can be effortlessly produced and processed at temperatures between 120-140 °C (hot mix);

- Emissions of emissions, vapors and aerosols at these lower temperatures are minimal, remaining well below the limits set forth in the Occupational Health and Safety Standards;

- It thus fits perfectly within the ambition of Bouwend Nederland to stop producing high-temperature road asphalt (hot mix) by 2025;

- Colorless binder is fully compatible with standard bitumen. Recycling of colored asphalt is therefore quite possible. For horizontal recycling, creating optimum reuse, the advice is to store color asphalt PR material separately at asphalt banking and power plants.

Therefore, based on practical experience, there is no indication that synthetic pigmentable colorless binders would be less responsible, sustainable and circular than currently available alternatives.

The full research report by Latexfalt in collaboration with Ooms Products BV - Sealoflex can be read on the Ooms Products website.