Thanks to innovation on the way to 100% Predictive Maintenance

Much infrastructure from the second period of the last century is in need of major maintenance. Croonwolter&dros specializes in such maintenance. We sit down with Celeste Martens and Guido Koopmans, both Maintenance Manager in the Infra division of Croonwolter&dros, to talk about practice and the future of major maintenance.

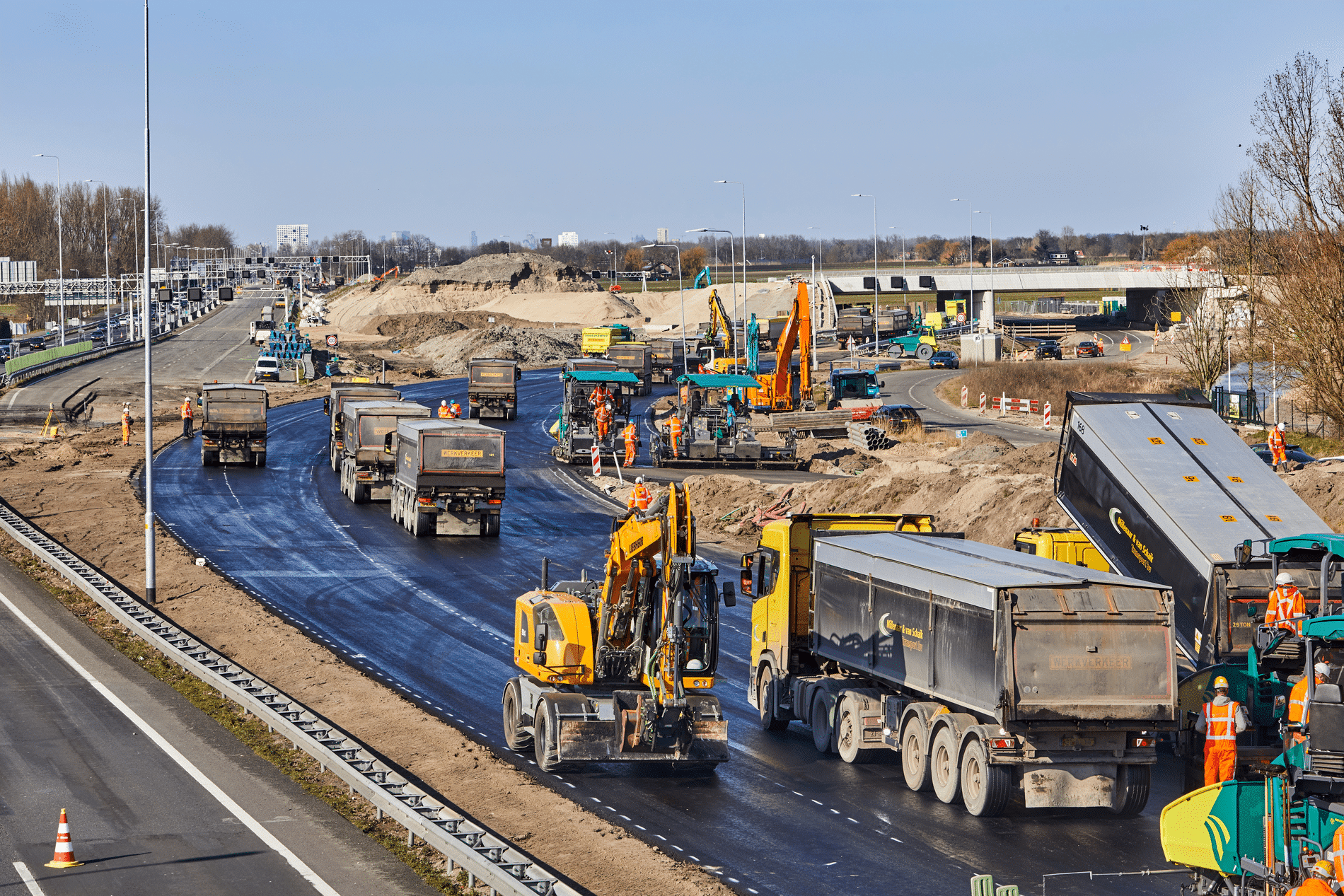

Guido Koopmans opens the talk, "25 % of Croonwolter&dros Infra's revenue comes from long-term maintenance contracts. Our strategy is aimed at further revenue growth in maintenance, up to half of total revenue. This is in line with the vision of Rijkswaterstaat. We are currently facing a major renovation task for the existing tunnels and civil engineering works, and we as Croonwolter&dros are happy to help.

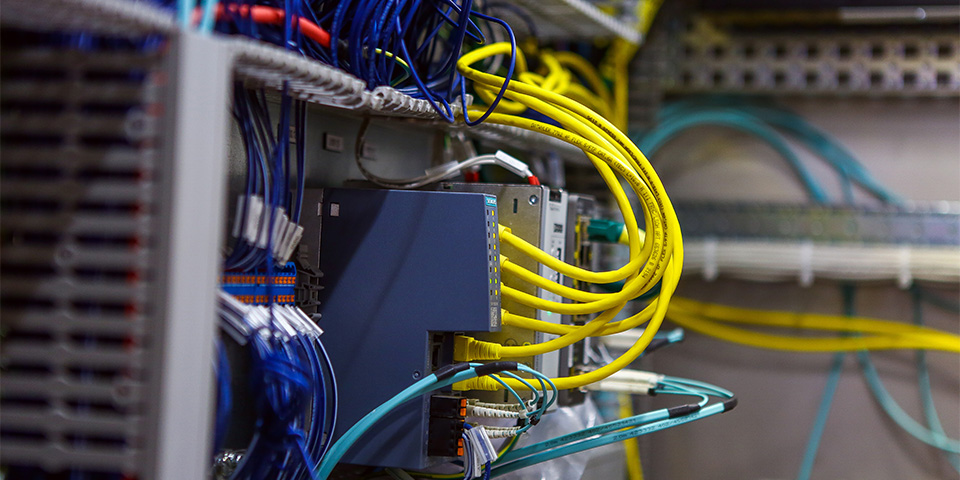

With new techniques, sensors generate data and transmit it via Internet of Things to intelligent systems that analyze that data.

Sustainable and future-proof

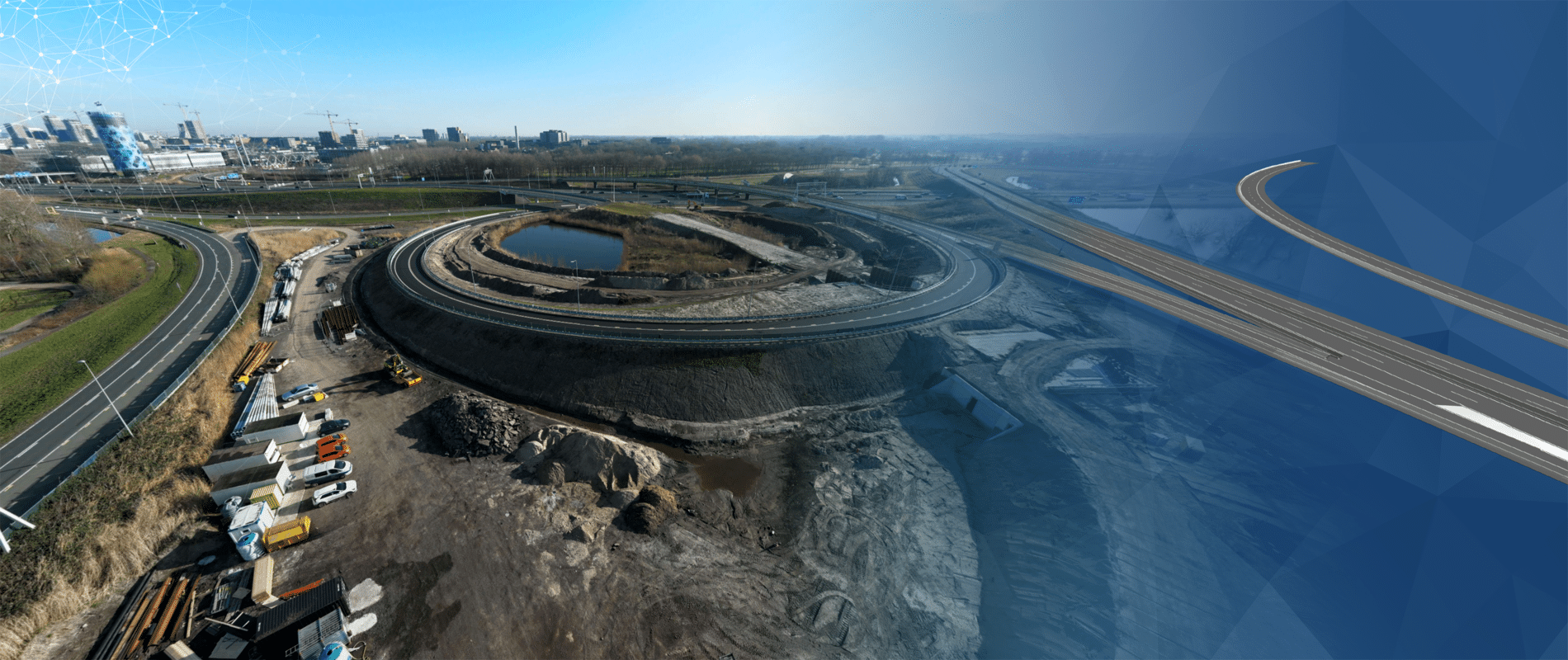

Instead of talking about an "assumed maintenance contract," we prefer to talk about a "conservation contract. Conservation goes beyond just performing maintenance. By performing analysis, you can increase availability and quality of service. Because you have to grow along with developments in technology, this is not just about maintenance, but also about sustainability and future-proofing," explains Guido Koopmans.

We provide clients with advice on how to reduce CO2-emissions, sustainability and circularity. That's the beauty of maintenance, we tackle the technical challenges together with the client and achieve our goals together."

Guido Koopmans, Manager of Maintenance at Croonwolter&dros' Infra Division.

Proactively looking ahead in a maintenance plan

Customers are still sometimes surprised by what Croonwolter&dros offers them. "With an eye to the future, we offer a maintenance plan proactively. People often haven't thought about this themselves. We can do that because we are constantly innovating ourselves. That requires a culture change in our own organization. To be innovative, you need an innovative corporate culture. For culture change, you need leaders who set an example, who inspire the followers through their enthusiasm. That is very contagious and ensures acceleration," explains Guido Koopmans. "For that reason, we organize conferences on innovation and sustainability, where participants, clients and contractors meet to share knowledge."

Maintenance when needed

Celeste Martens, responsible for Asset Management, notes that Predictive Maintenance is in line with the fourth industrial revolution (Industry 4.0): "With new techniques, sensors generate data and transmit it via Internet of Things to intelligent systems that analyze this data. This allows maintenance to take place at the right time. So no longer preventive or corrective, but when needed. With enough data and the right algorithmic calculations, predictive maintenance can be done. Predictive Maintenance is now a reality and has the future, especially since the technology needed for it is becoming more and more affordable."

Celeste Martens, Manager of Maintenance at Croonwolter&dros' Infra Division.

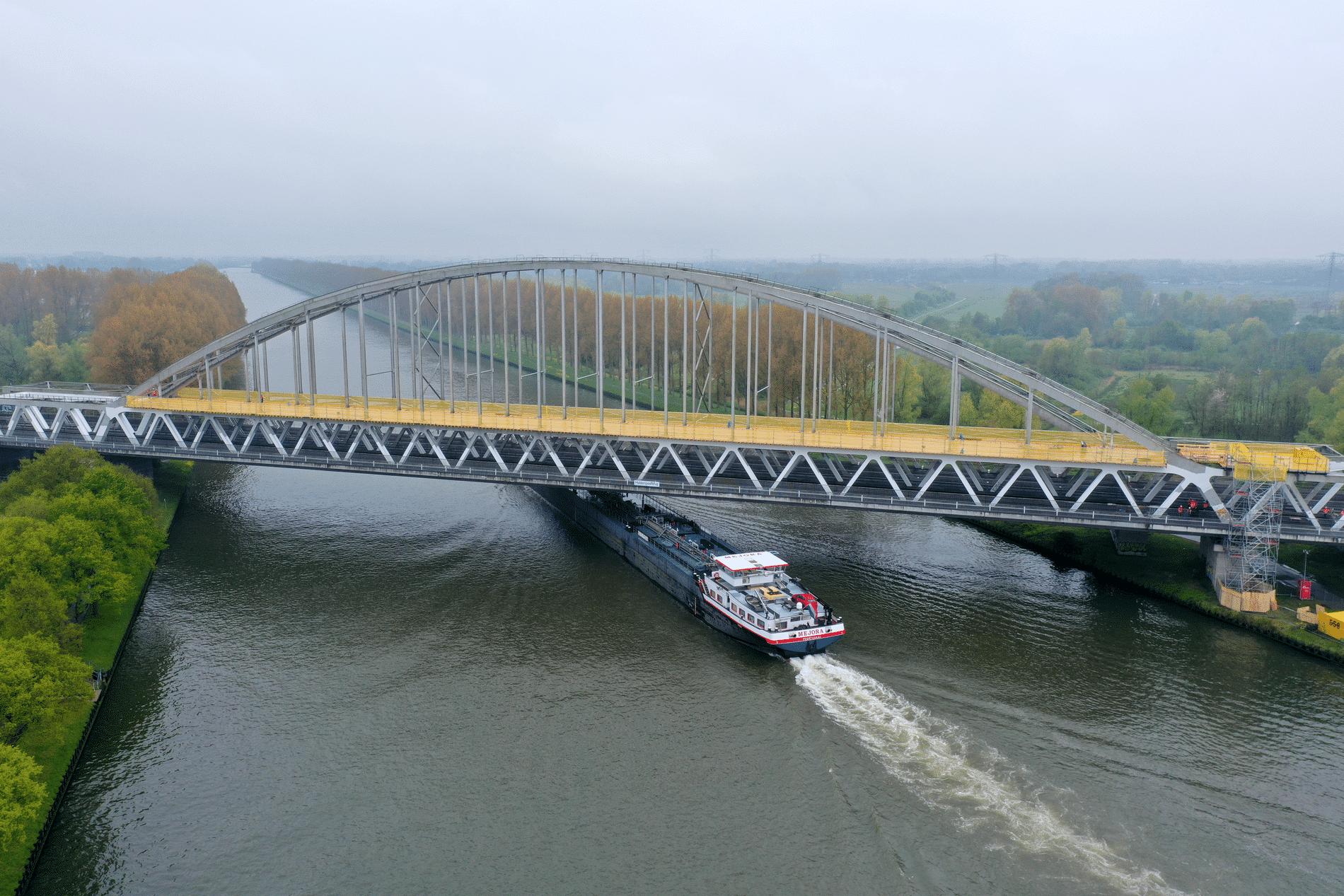

Predictive Maintenance is an ideal working method for the assets maintained by Croonwolter&dros. "Long-term contracts we carry out anyway on the basis of Predictive Maintenance," Celeste Martens continues. "As an example, I like to mention Sluis Eefde. In the design, we have well justified where and why we want to monitor with sensors. We can make things like energy consumption, wear and tear and sustainability transparent. Now it's still a voyage of discovery as to which things to monitor, because the possibilities are almost endless. Asset management is about the entire life cycle, from tender to demolition, about optimizing the balance between costs, risks and performance over the lifetime of the assets. To do this well and make good decisions, you need good people, with the right knowledge and reliable data. Condition monitoring is here to stay and is expected to become the norm for 75% of assets," Celeste Martens concludes.

Croonwolter&dros

P.O. Box 6073, 3002 AB Rotterdam

T +31 88 923 58 99

E remmy.uffen@croonwolterendros.nl

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Croonwolter&dros.

Contact opnemen

Contact opnemen