Pumps are the beating heart of the Dutch water market

We only need to look at two important, current issues to see the importance of pumping: a changing water regime due to climate change and the increasing demand for clean drinking water. We fight against and live with water in the Netherlands, from time immemorial. In absolute correlation, Flowserve has a unique historical heritage, namely expertise in pump technology. In a conversation with Bart van der Slik, Manager Sales Netherlands and Jan van Diesen, Manager Project Management, they explain to us where the leading position in pump technology comes from.

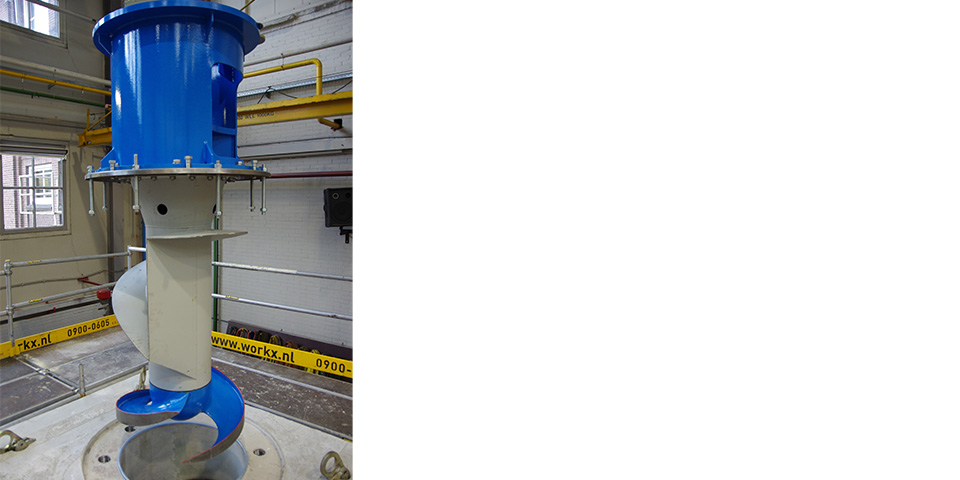

Flowserve fish-safe concrete volute pump CVPS-F85.

Owner of intellectual property and heritage

"Generally speaking, Flowserve is associated with pumping oil and gas. In addition, the expertise of the Dutch branch of Flowserve, which was originally American, is very clearly in the water market," Van der Slik opens the conversation. Added Van Diesen: "Stork was split into parts at the time and Flowserve took over Stork's pump division in Hengelo at that time. Thus Flowserve became the owner of the intellectual property and heritage of Stork Engineered pump technology. We then proceeded with this knowledge and expertise under our own banner. Flowserve should therefore not be confused with the Stork brand name, which still exists."

Strong presence in the water market

Flowserve has several "strike zones"-read: markets-in which it moves with a strategic focus, water being one of them. "The specialism in water displacement and drinking water, strategically speaking, is a truly Dutch matter for Flowserve," Van der Slik suggests. "That doesn't take away from the fact that we use our local expertise on a global scale. We even employ a Global Business Developer for that purpose." That Flowserve Netherlands operates globally is evident from an example that Van Diesen cites: "The hurricane-ravaged south of America and the resulting danger of flooding prompted the American city of Dallas to purchase large water displacement pumps from us. A salient detail here is that Flowserve's headquarters is in Dallas : a fine example of Flowserve's reach as a multinational company."

Installation of precast concrete slug houses.

What does the strategic vision mean at the local level?

Flowserve has a stringent legal profile, we learn. Van Diesen says: "However, the UAV conditions in the Netherlands did not match this legal profile. Flowserve therefore spoke intensively with customers, carried out risk assessment and benchmarking, and on the basis of this decided to translate the global risk profile into a local profile, taking into account the specific requirements of this market." Van der Slik adds: "Our clients still sometimes had the idea that we had adopted a strict attitude in recent years, but thanks to the new risk screening we can once again compete in the market. To put our money where our mouth is, the organizational set-up has also been adjusted. For example, we now have a specific Water Unit, including two sales engineers-Jan Vervoort and Ronald Lammerink-who are 100% focused on water. With this organizational set-up, with specifically market-oriented teams for both customer contact and operational execution, we can once again serve the water market optimally."

Several entities under one roof

The translation of Flowserve's strategy to the local level is done in a smart way. Etten-Leur is home to the Flowserve Campus: "There you'll find several entities under one roof: the Seal Manufacturing Hub, the Seal Quick Response Center, the Pump Parts Manufacturing Center and the Pump Quick Response Center (QRC). It's an aftermarket operation. The Pump QRC specializes in upgrading and repairing existing pumps. Consider that the Netherlands is full of pumps once supplied by Stork and you understand the importance of this unit," Van Diesen said.

In addition, we find within the Flowserve Campus the International Field Service group, specializing in installation and maintenance. "The Central Engineering group also operates out of our Campus, serving the various entities. They are leading in product engineering and development and do this for Flowserve worldwide. Even installation abroad is done by our own teams," Van Diesen outlines. "Add to that the fact that we have our own test center where we can test up to 18 megawatts and we are directly connected to the power grid at 150 kV. We also test there for third parties. Finally, a Pump Quick Response Center of Flowserve is also stationed in Hulst, for fast and effective repairs. Hulst is equipped, among other things, for the drinking water market."

Cross-sectional spui and pump complex Den Oever, source: Levvel - Project Afsluitdijk.

Fish safety guaranteed

Van der Slik: "Flowserve is known for its fish-safe pumping solutions. This has therefore been tested extensively. We have done a lot of research into this; our experts even helped develop a NEN standard for this for the water market." Sustainability doesn't stop there for Flowserve, however. "A nice example of one of our market distinctive applications are our special bearings, without grease lubrication. Emission-free, therefore, due to less release of harmful substances into the water," Van Diesen concludes.

Flowserve B.V.

Parallelweg 6, 4878 AH Etten-Leur

T +31 76 502 8100

+31 76 502 8200

E RLammerink@flowserve.com

JVervoort@flowserve.com

www.flowserve.com