On the need for a baseline measurement

And how it is embedded in the work process

We cannot overstate the importance of the construction baseline measurement. This accurate 3D recording of positions, areas and spaces of the construction site, ensures that the dimensional assumptions of a project are correct. It helps prevent duplication and adjustments during execution and reduce the associated failure costs. Not for nothing have big names in real estate, construction, engineering and infrastructure firmly integrated zero measurement into their work process. In this article we learn more about zero measurement in Heijmans' construction practice. And we present you with a practical white paper about the zero measurement they collaborated on.

Accuracy beforehand, demonstrability afterwards

Heijmans has fully integrated zero measurement into the work process. "In civil maintenance projects, the zero measurement already starts in the tender phase, in most projects it is only after the contract is awarded," says Pieter van Dueren den Hollander, project manager at Heijmans. "But always before the start of the design phase, so that we define correct starting points in advance, tackle challenges in time and adjust the design where necessary." Van Dueren den Hollander believes it is better to work on the design two weeks longer than to encounter all kinds of surprises during the implementation phase. "We also use the baseline and interim measurements for demonstrability afterwards, so we can always show what the situation was like before we started working on it."

Zero measurement in practice: project Zuidas

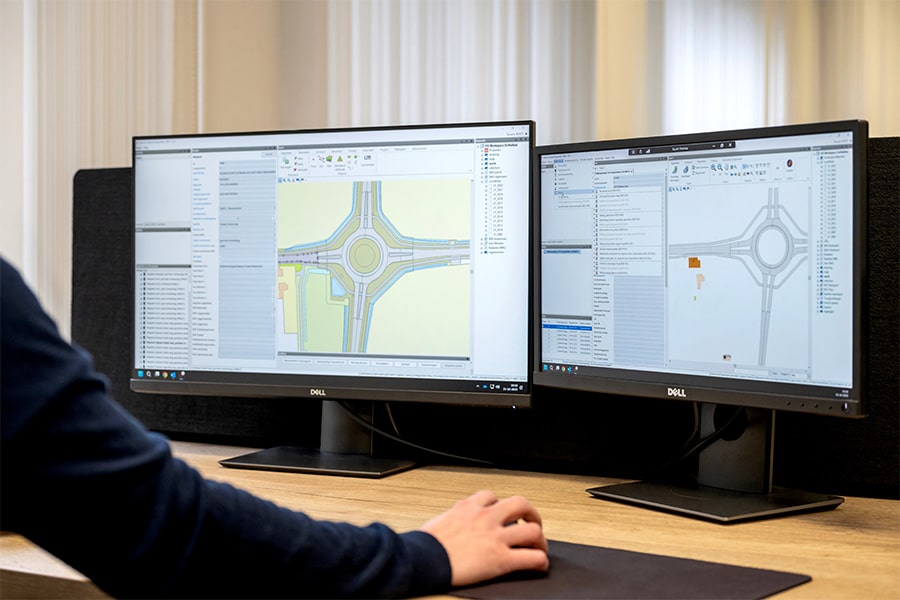

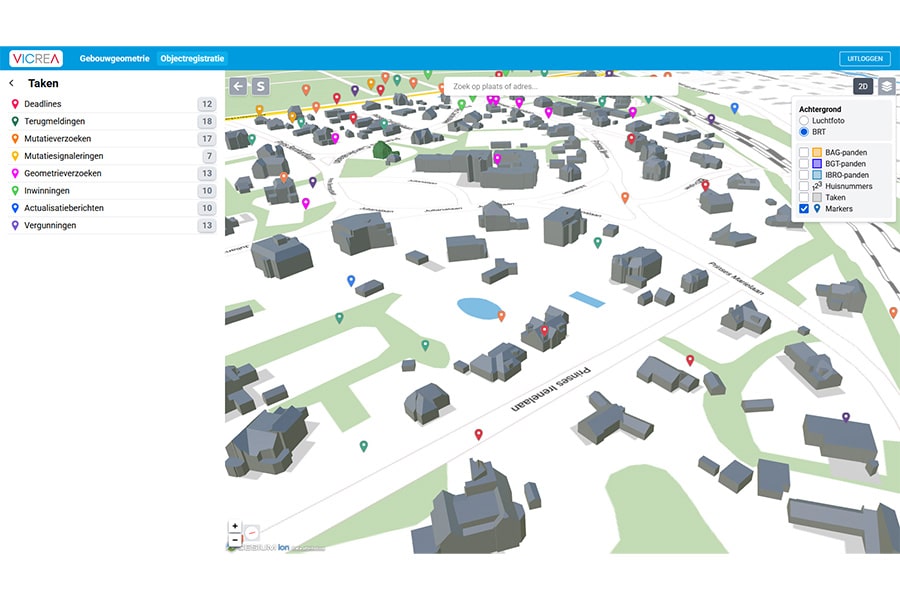

A good practical example is the construction of a new public transport terminal on the Zuidas in Amsterdam, where Heijmans carried out a detailed zero measurement after being awarded the contract. "The design phase starts with checking the data collection drawing made during the tender. This incorporates all the data provided by the client. A data-collection coordinator is appointed, who connects all disciplines and ensures that all parties involved supply the necessary data. Then - with Total Stations and 3D laser scanners - the construction site and surroundings are measured. Sometimes we do that ourselves, sometimes we outsource it. We find it important that the measuring equipment used is calibrated annually, so that we can assume that the data generated is reliable. We then make a Digital Twin, a virtual copy of the construction site, from the 3D point cloud that emerges from the scan. The digital design is based on this Digital Twin. And then we actually rebuild the work on the construction site." The zero measurement keeps the risks for the Zuidas project manageable. "By checking everything in advance on the scan and including it in the design, you avoid surprises during execution and stagnation of construction. The costs precede the benefits. After all, prevention is better than cure," says Van Dueren den Hollander.

Looking even wider

Robin Dullens, also project manager at Heijmans, emphasizes the importance of such a construction baseline measurement. "To embed it in the work process, it is important to involve new colleagues in this process immediately. Because checking is also a matter of cultivating habit," he knows from experience. And he is not just talking about gathering information for the baseline measurement: using the baseline measurement in the rest of the project is also crucial. "In addition to the process and technology, you have to deal with people," Dullens says. "The plans and measurements can be as good as they are, if people don't use them properly you are nowhere. That means training, communicating well and making sure everyone knows what their job is every day. That is why the data acquisition coordinator remains a crucial pivot during the implementation phase." Dullens also emphasizes that it is important to look beyond just the construction baseline in the present: "Look at the past and the future as well, so that you have all the information from the construction site before you start the execution phase."

How to get a good architectural zero measurement in practice, what the tasks of the main contractor and subcontractors are, and handy tips for embedding the zero measurement in the work process can all be read in Topcon's white paper, which can be downloaded via: topconpositioning.com/en/zero-measurement-the-construction.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Topcon Positioning Netherlands.

Contact opnemen

Contact opnemen