Sewage pumps: customization from start to finish

Pentair has been commissioned to supply ten Pentair Fairbanks Nijhuis sewage pumps for the renovation and renewal of the Brabantse Delta Water Board's wastewater pressure pipe (AWP). According to project manager Edwin Wolterink, customization from start to finish, with the pumps in the two pressure stations also being fitted with low-clogging impellers.

On behalf of GMB Water Quality & Installations, Pentair's Winterswijk branch will supply the pumps for the pressure stations in Roosendaal and Bergen op Zoom and the effluent pumping station of the WWTP in Bath. "The project has two major challenges for us, for which we have found a suitable solution. First, to address the clogging problem in the two pressure stations and second, to achieve the requested high efficiency in order to operate the effluent pumping station as efficiently as possible. Because the existing pumps are from a different supplier, the new pumps had to be customized to fit one-to-one in the existing installation. A nice custom solution, with which we keep the conversion costs to a minimum."

Clogging problem

AWP 2.0 is one of the larger sewage systems in the Netherlands. "Like many other systems, Brabantse Delta's 60-kilometer AWP is struggling with clogging problems," says Ester Reusink, manager of communications at Pentair. "The proliferation of non-soluble fiber-rich wipes is a growing problem in the sewer world. Current pumps regularly suffer downtime due to clogging caused by these wipes ending up in the sewer, among other things." According to Wolterink, this has to do with the wrong geometry of the impellers that cause a lot of trouble. The Winterswijk branch of Pentair is constantly engaged in the further development of pumps and pumping systems. "The composition of sewage water has changed enormously. For example, the amount of fibrous wipes increases every year. Pentair has delved into this issue in recent years and we are responding to it by continuing to improve our impellers."

With its own foundry, machining, assembly and testing facility, Pentair Fairbanks Nijhuis takes care of its customers from start to finish.

Scale model test

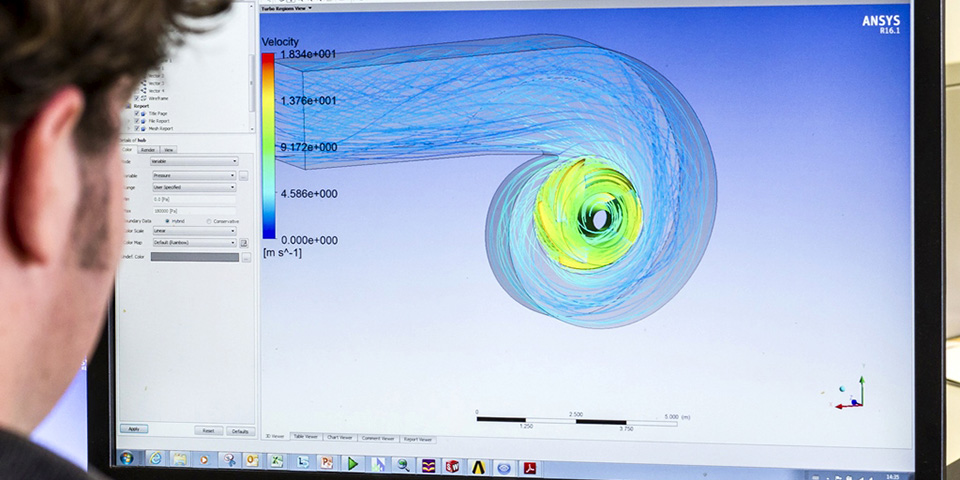

Another advantage of Pentair's pumps is that they have a very wide operating range. Wolterink: "The capacity of the pumps we apply in West Brabant varies from 2,000 m3 per hour in dry weather up to 20,000 m3 during rainfall. In all conditions, the pump performance is excellent, so the discharge capacity is maximized at all times. We realized the design and calculation of the pumps entirely in-house and tailored them to the specific situation. In fact, we have our own R&D and engineering department in Winterswijk. With our own foundry, machining, assembly and test facility, we relieve our customers of all their concerns from start to finish. All pumps have already been successfully tested during our scale model test in December last year."

The renovation is being carried out in phases because the sewage pumping stations and the WWTP effluent pumping station must continue to operate as usual during the renovation. The first pump will be replaced in December this year.

In addition, Pentair has entered into a multi-year maintenance contract with the Brabantse Delta Water Board "After the large-scale replacement task, we provide maintenance on the pumps for fifteen years," says Reusink. "So we facilitate the water board from start to finish, from design and production to installation and maintenance."