3D scanning: obtaining 3D images quickly, easily and accurately

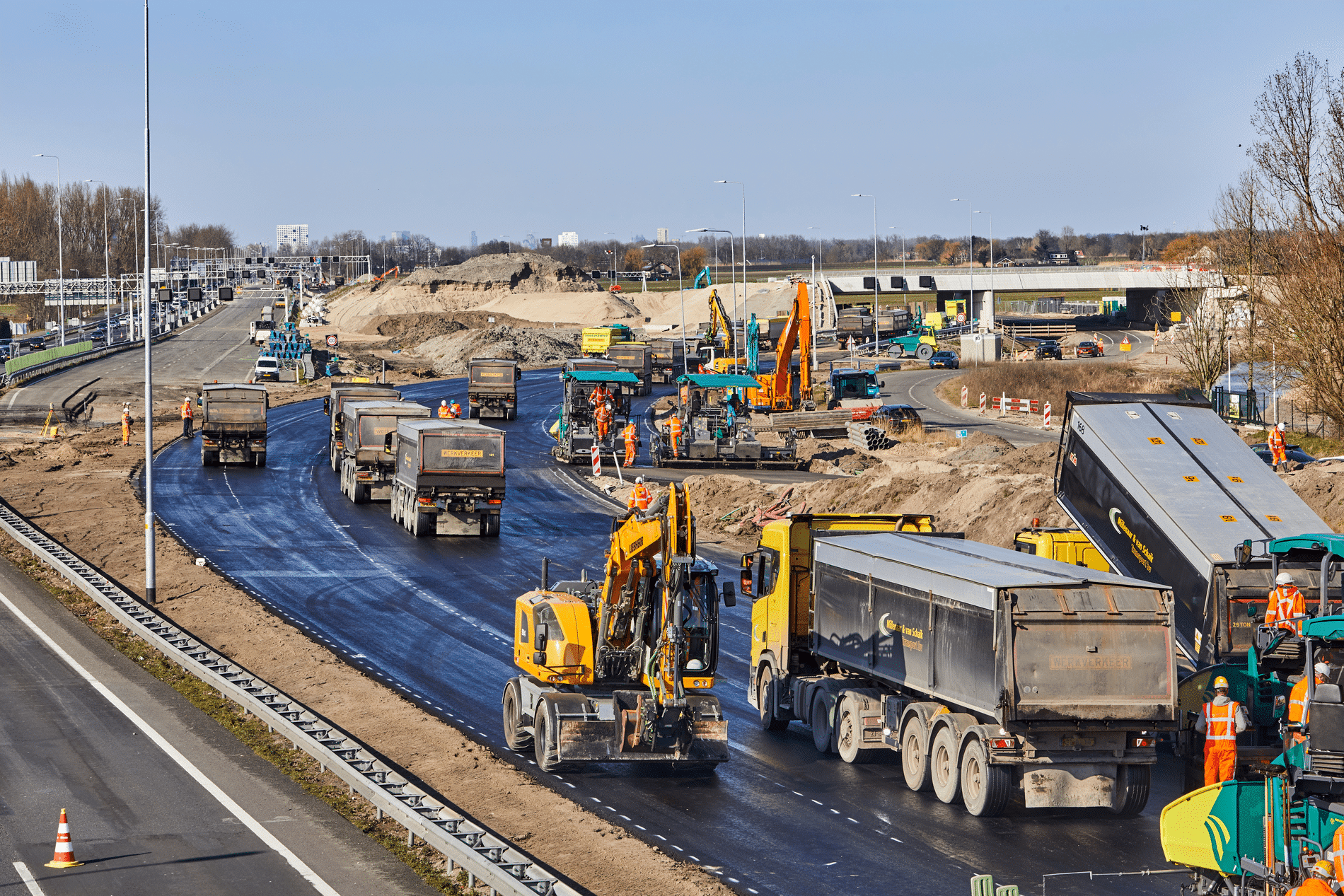

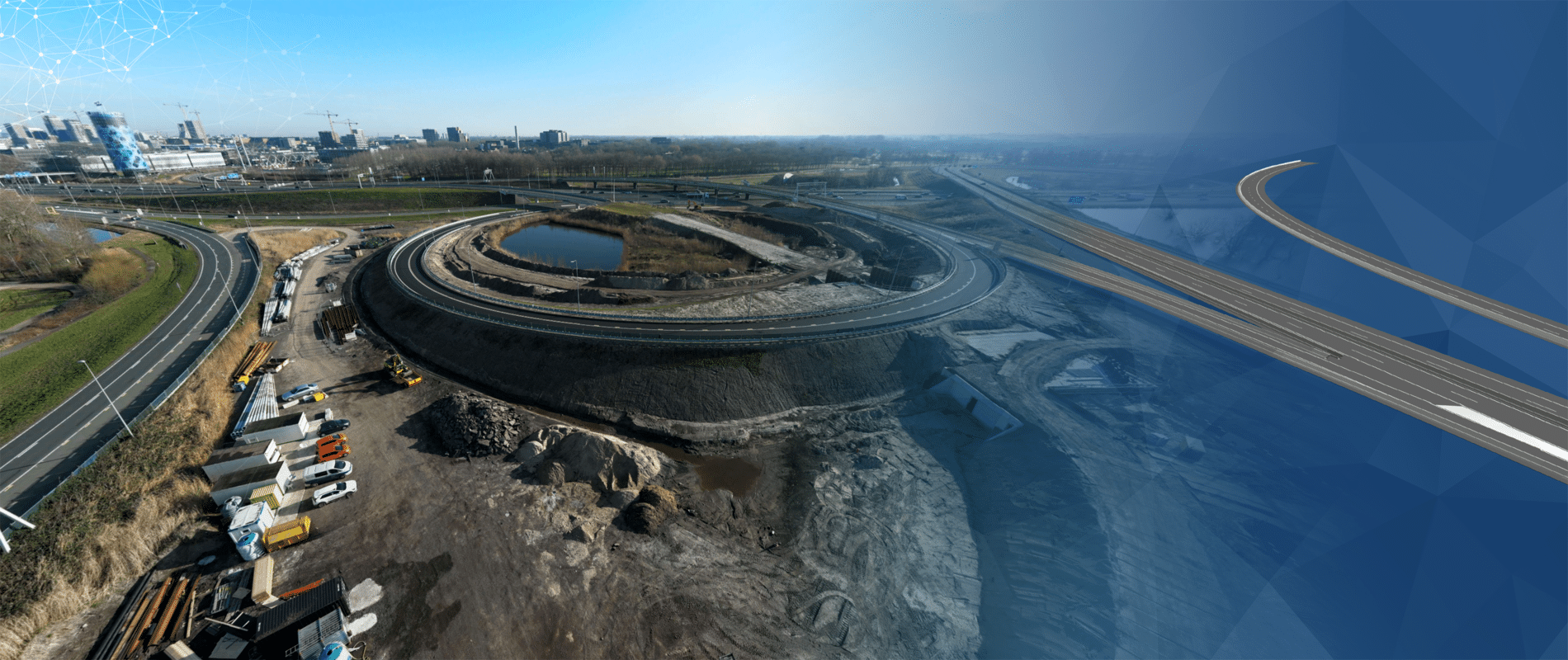

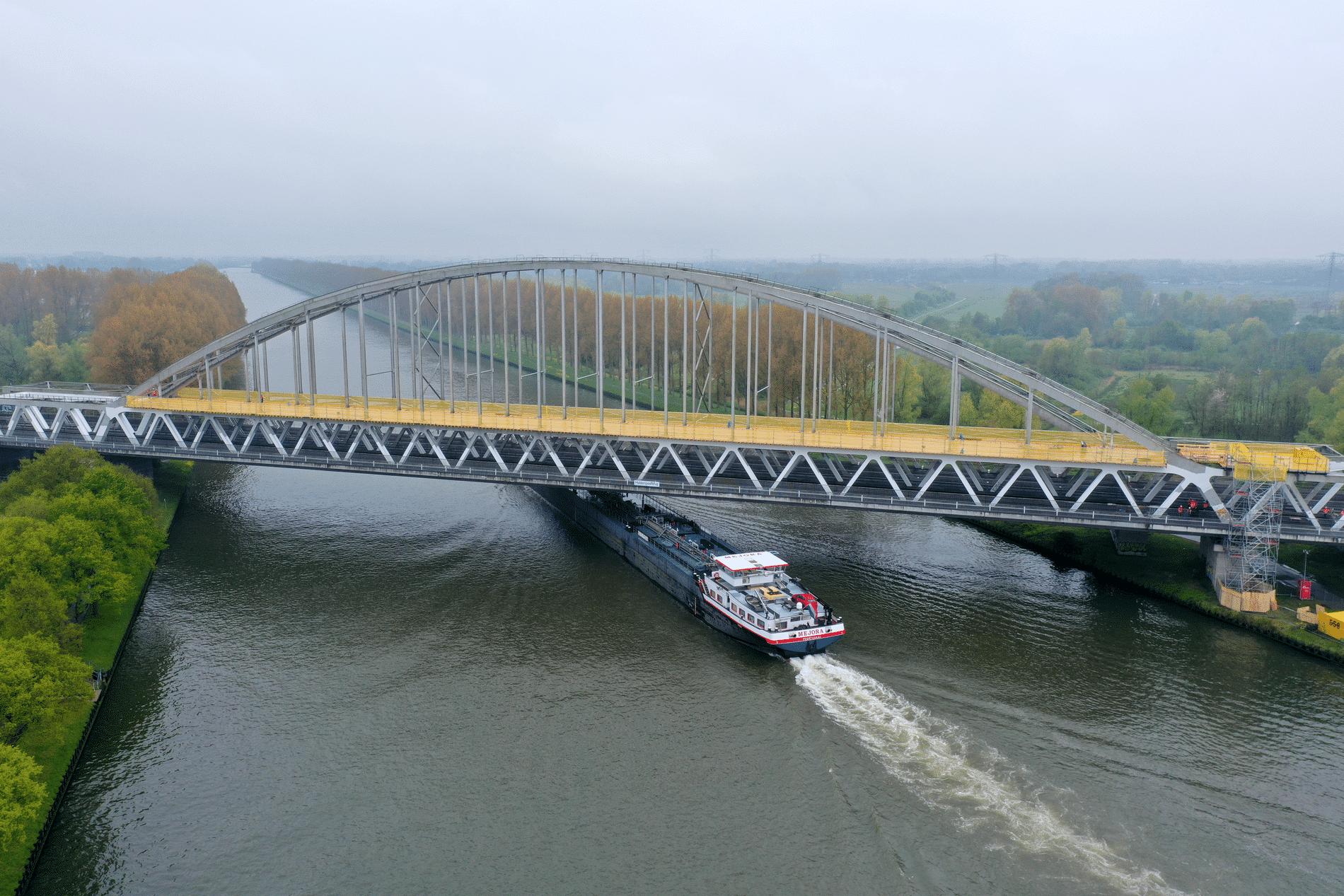

When developing a new project such as a traffic circle, road, structure or bridge, the first thing to do is to accurately visualize the existing situation. Using 3D scanners, surveyors and professionals are able to generate 3D images very quickly, easily and extremely accurately. With the acquired data, a designer can get to work and it becomes clear to the client exactly how much soil must be supplied or excavated for the construction. Not surprisingly, 3D scanning is becoming increasingly common.

Surveying 2.0

Geometius, supplier of measuring equipment and systems for positioning (GNSS) and surveying, geographic and hydrographic applications, really takes surveying to the next level. With a wide range of UAVs, 3D scanners and user-friendly processing software, images can be captured and processed both on the ground and in the air. Geometius is a supplier of Trimble instruments and software in the Netherlands, including the Trimble SX 10 Scanning Total Station.

Surveyor Rein Blokhuis (ADCIM) at work with Geometius' Trimble SX10 at the Maasvlakte.

3D scanning and measuring in one instrument

The SX10 is an accurate Total Station and high speed 3D scanner in one instrument. It features 3 HDR cameras with VISION technology and works to millimeter accuracy. With a measurement range of up to 600 meters, the SX10 scans as many as 26,600 points per second, making it unique on the market.

'Cool tool with handy scan tool'

That the Trimble SX10 is completely changing the way we work, agrees Rein Blokhuis, surveyor at ADCIM. Blokhuis worked on the Maasvlakte on the construction of the Princess Amalia flyover and now on the CER (Container Exchange Route) track between container terminals. "Truly a cool instrument with handy scanning tool that allows you to measure large areas and collect a lot of data in a short time. During the construction of the Princess Amalia Viaduct, the client Port of Rotterdam wanted to know what the deflections of the reinforced soil were. Now we are in the process of creating a fourteen-kilometer-long runway on the Maasvlakte. This can be beautifully visualized using the 3D scanner." In the meantime, Blokhuis visualizes the progress so that the client and contractor can see for themselves whether it meets the set requirements.

Blokhuis, in the business for 34 years, once started with an angle mirror and measuring tapes. I was one of the first Dutch with a robotic instrument from Trimble. For many a big transition but I was enormously interested in the technology and soon became more and more handy." He finds the move to scan mode and 3D imaging a hugely fun and interesting development.

The Trimble Total Station Studio SX10.

Convenience. Quality. Speed.

Blokhuis works with the SX10 by default. "It's so much more than a conventional tool. That you're not looking through a telescope is a matter of getting used to," Blokhuis believes. "On the field book, I see exactly what the SX10 sees. At any time. This changes everything in the field. You can zoom in and out excellently, and instead of measuring samples you now scan the whole plane. With the familiar survey workflow, you collect all the data you need at once. It's not just a Total Station, it's also a laser scanner and camera."

Software

In addition to measuring, Blokhuis says data processing is also simple and insightful. "The software and the measuring instruments fit together perfectly, the same goes for machine control. Thanks to the good link, the data is easy to read and process." Blokhuis concludes, "People nowadays ask if I can scan something instead of measuring it. Then you know it's a good development."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Geometius.

Contact opnemen

Contact opnemen