'With ArcGIS, we work many times more efficiently on the railroad'

From excel lists to an up-to-date digital map

The way in which BAM Infra Nederland uses ArcGIS when planning and carrying out work on the railroad was this year's Dutch entry for the Digital Construction Awards, an internal competition at BAM. In this way, BAM works faster and more efficiently.

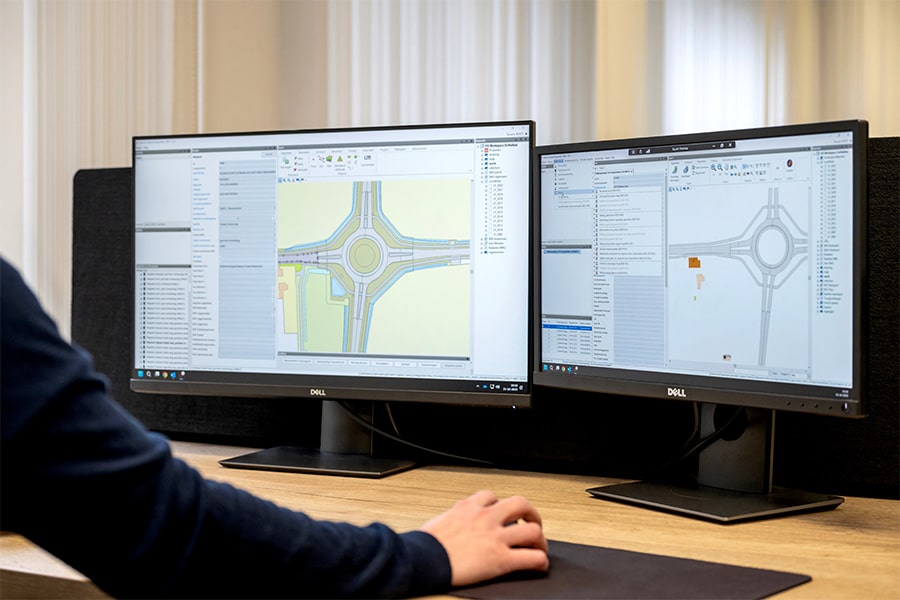

Wouter Könst is a GIS and geo-information consultant at BAM and designed the digital working method in ArcGIS. Könst: "A year ago, our employees working on the track at night were still working with a paper work drawing. This indicated where something had to be done. Besides the fact that working drawings are awkward in the dark, it increases the risk of error when changes are made and the information on paper is quickly out of date." That could be done differently. Könst went to work on a GIS that allows both planners and employees on the track to work directly and on location.

Current Dates

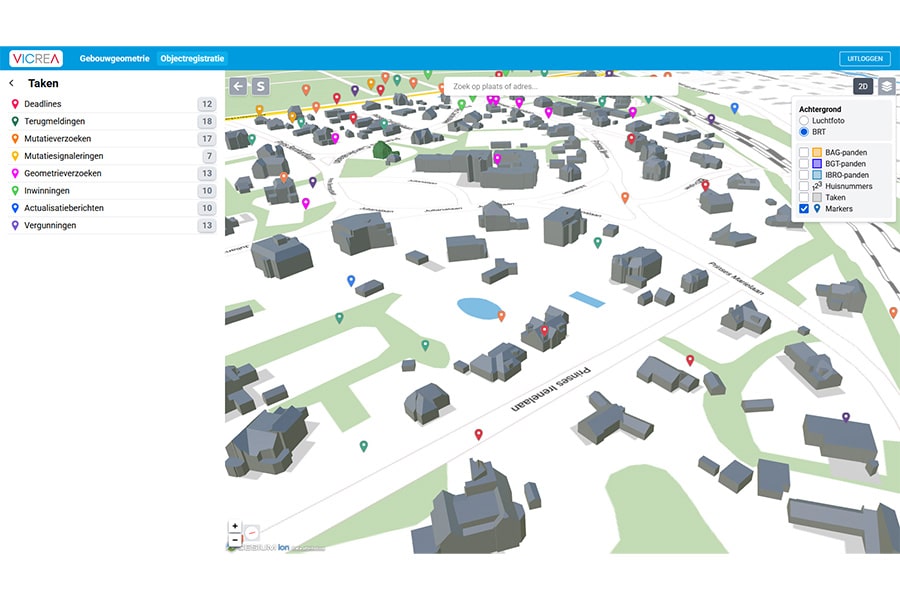

BAM uses ProRail's public data for this system. From data on track, signals and overhead lines to aerial photos of the locations in question. "There is no more up-to-date data about the situation of the track. If things change, it changes in our system immediately," Könst says. The data are incorporated into an app that can be operated on a tablet, mobile or PC. "Measurement results are displayed as dots on the map. Engineers study these measurement results and draw a line over pieces that need to be worked on. These become visible in the system as assignments. When employees on the track have finished an assignment, they can adjust it directly in the app and the dots change color. This system is linked to our SharePoint environment so everyone sees the current status immediately."

From excel list to clear map

But working in ArcGIS provides even more benefits for BAM. "Previously, we worked using excel lists with measurement data. With these we determined where work was needed. The disadvantage of this is that it is not easy to see which locations are close together. In the GIS, the map shows at a glance which locations require work, and therefore which jobs are close together. This allows us to schedule work more efficiently," Könst explains. But it also comes in handy during the work. "Sometimes things happen during the work and the machinists have time to spare after an assignment. They can now see for themselves in the GIS environment that there is another job to do nearby and pick it up immediately. That saves a lot of time." In addition, according to Könst, the improved communication is a big win. "Mutual cooperation is much easier. Employees have to explain less to each other because everyone has the same information at their disposal. So they can get to the heart of the matter faster."

Learning from each other

At present, the new way of working is not yet being used by all departments, but if it is up to Könst, that will soon change. "We are currently in discussions with the department that grinds tracks to also start working this way. ProRail is also involved in this because we notice that they are doing more and more with GIS. In this way, we hope to learn from each other and bring our working methods closer together." Now that the GIS is up and running at BAM, Könst's work for this department is over. "We have set up the system so that the user can do everything himself. Unless the technology needs to be expanded, they won't need me anymore."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Esri Netherlands.

Contact opnemen

Contact opnemen