A durable, clean and safe alternative as an aggregate for the concrete products industry

The central government's program "The Netherlands Circular in 2050" offers an answer to the great challenge in the 21st century to deal more efficiently with raw materials. In the context of that resource efficiency, a green deal has been signed between the ministry and the association of waste companies, where it has been agreed to high-quality reuse of bottom ash.

One company that has been applying knowledge of (soil) cleaning and immobilization techniques in an innovative way to produce secondary raw materials for decades is Mineralz, a subsidiary of Renewi. Paul Dijkman, director Mineralz: "Based on the green deal, we looked at how we could apply our cleaning techniques to the cleaning of bottom ash. In 2016, we opened the FORZ®Factory, the first plant to convert bottom ash from waste-to-energy plants into sustainable, clean and safe raw materials that we sell under our brand name FORZ® marketing."

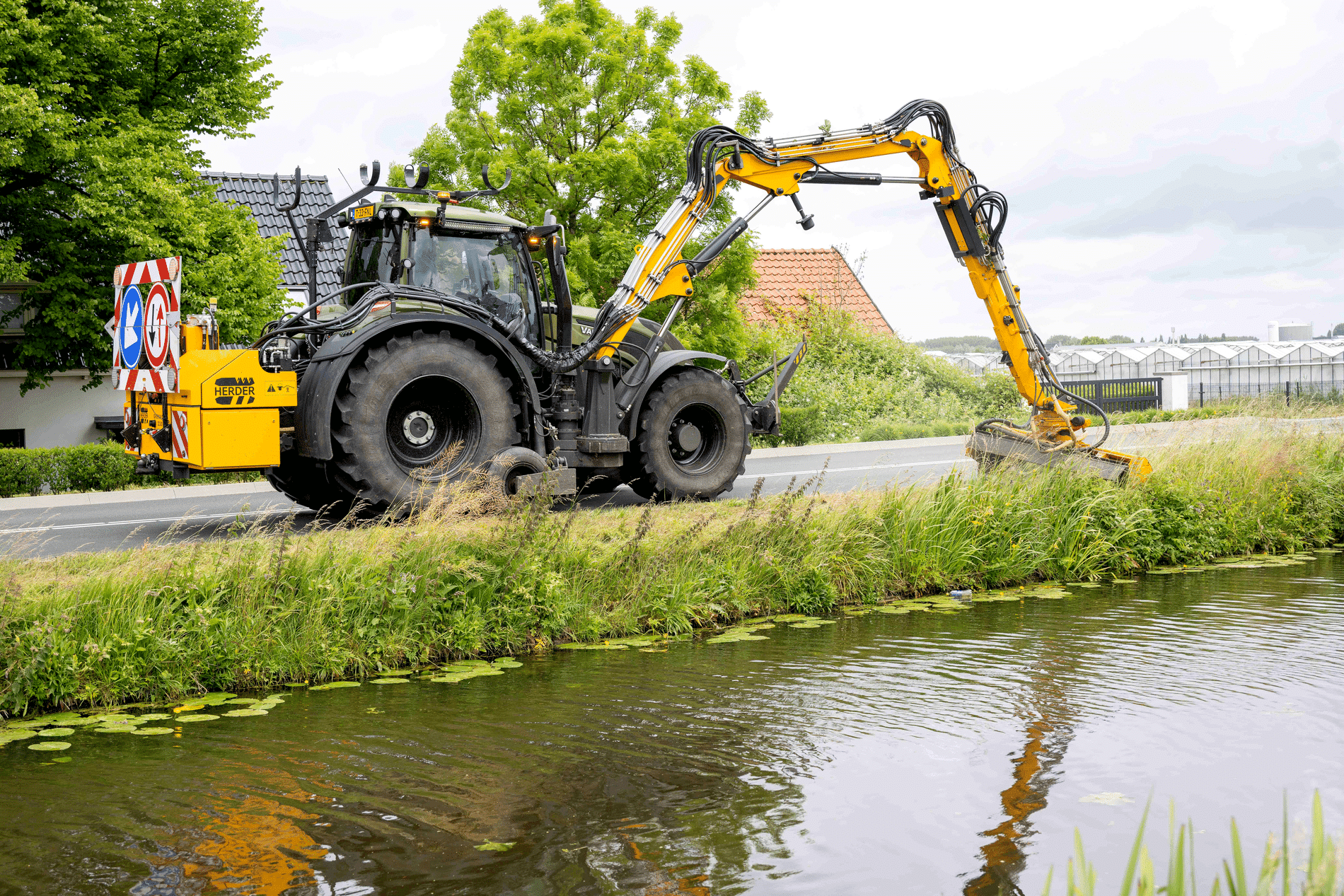

Grass concrete tiles from V.d. Bosch Beton b.v.

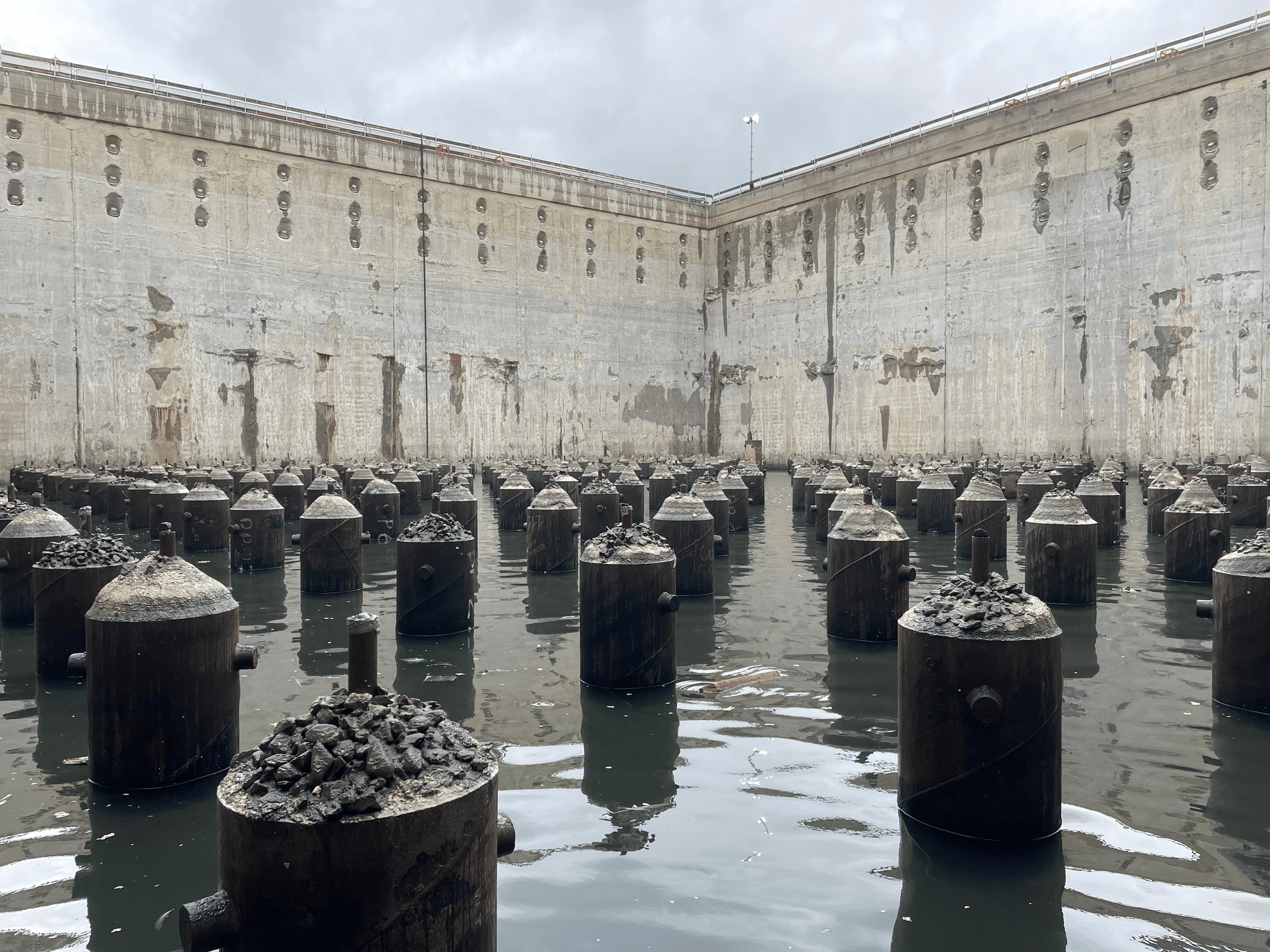

Urban Mining

"From municipal household waste, we produce an alternative to sand and gravel as aggregates for the concrete products industry, among others: FORZ®Aggregates. We supply various concrete product manufacturers and often the end product is used again by municipalities in the form of clinkers, curb stones, paving stones, et cetera. This way the waste goes 'Off the street, into the street' and is eminently a great way to make your municipality more sustainable!"

Clean, safe and sustainable

"We supply clean, safe and sustainable raw materials. The cleaning process is very important here. The concrete brick must be as hard in terms of compressive strength as a brick made purely from primary material. In addition, the concrete brick must be able to enter the reuse circuit, which makes the brick sustainable."

Cross-section of a concrete brick with FORZ®Inside.

Ceramic industry

As proof that our raw materials are clean as well as safe, we see that FORZ is used not only for construction and infrastructure.®. This is evident in a collaboration between Mineralz and Studio Mixtura, in which an innovative application of secondary raw materials for the ceramic industry has been developed. With FORZ®Glaze gives old tiles and dishes a second life.

Know-how and technology

"We also offer a solution for cementitious concrete," Dijkman continued. SQAPE, a joint venture between Mineralz and Cementbouw, developed a patented technology that provides an affordable and sustainable alternative to concrete that reduces up to 80% of CO2 and a particularly low MKI value can be realized. By working with tailor-made formulations we are able to control the shrinkage in the material and achieve a high (acid) resistance, making SQAPE a geopolymer system for sustainable and affordable building materials. Concrete manufacturers can use our technology prefabricated or as mortar." Dijkman mentions as examples V.d. Bosch Beton b.v. from Almelo, they supply Reduton® products made on the basis of SQAPE technology. Struyk Verwo Infra also supplies various stone and tile products made from Geopolymer concrete under the CERO name.

Traffic circle constructed with RAMAC.

Ready Mix Concrete

"To complete the overall picture, there is an alternative to conventional Ready Mix Concrete based on the patented and proven SQAPE geopolymer technology: RAMAC. A concrete mortar for durable and resistant construction, due to tailored strength, reduced shrinkage and cracking, high freeze-thaw resistance, high acid and chemical resistance and low chloride intrusion. Thanks to its excellent adhesion to (conventional) concrete products, RAMAC would also be applicable in combination." Some of the licensees are A. Jansen BV, Cementbouw Betonmortel BV and Rouwmaat Group.

Dijkman concludes, "We are a developer/supplier of practically applicable and future-proof secondary raw materials created through our own innovations. In collaboration with chain partners such as universities, knowledge institutes and customers. We link that knowledge to the needs of the market. This is how we make our world a little cleaner all the time."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met v.d. Bosch Concrete b.v..

Contact opnemen

Contact opnemen